Boiling type concentrating machine

A boiling type concentrator and concentrate technology, which is applied to centrifuges and centrifuges with rotating drums to achieve the effects of large enrichment ratio, low power consumption and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

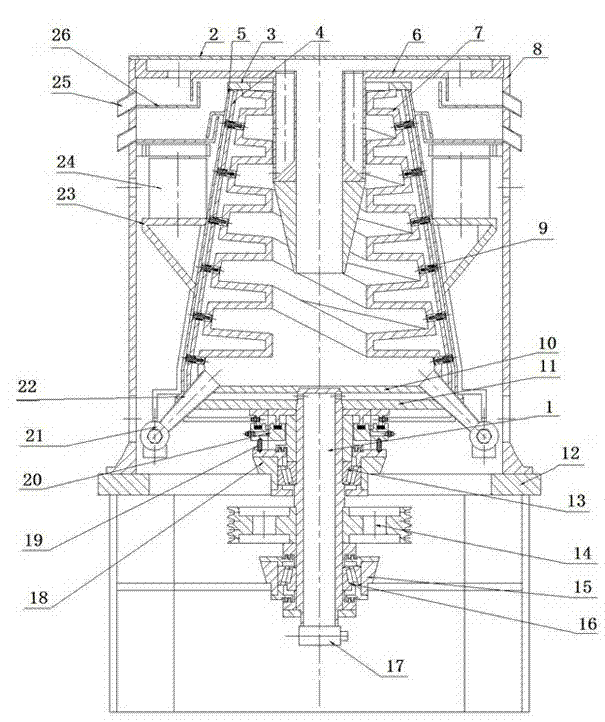

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

[0030] Such as figure 1 As shown, the fluidized mineral concentrator includes a casing 8, a support 12 connected with the bottom of the casing 8 by bolts, the top of the casing 8 is connected with a casing end cover 2 by bolts, and the casing end cover 2 is connected with a feeding device 6 by bolts, and The main shaft 1 located in the inner center of the housing 8 is characterized in that: the main shaft 1 is provided with a hub chassis 10 which is connected by a key connection, is sealed by an rubber ring, and rotates together with the main shaft 1, and is provided with a step positioning on the hub chassis 10. And welded, and the spiral hub 7 that rotates with the main shaft 1; the described main shaft 1 is provided with a water air jacket chassis 11 that is connected by a key, sealed by an rubber ring, and rotates with the main shaft 1; on the water air jacket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com