Integrated control system of wheel type engineering machine

A technology of construction machinery and comprehensive control, applied in the field of control systems, can solve the problems of not taking into account the directional stability of the whole vehicle, no real-time monitoring system of the whole pipeline, and low mobility of the vehicle, so as to ensure braking safety and safety. Reliability, improved braking maneuverability, natural pedal feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

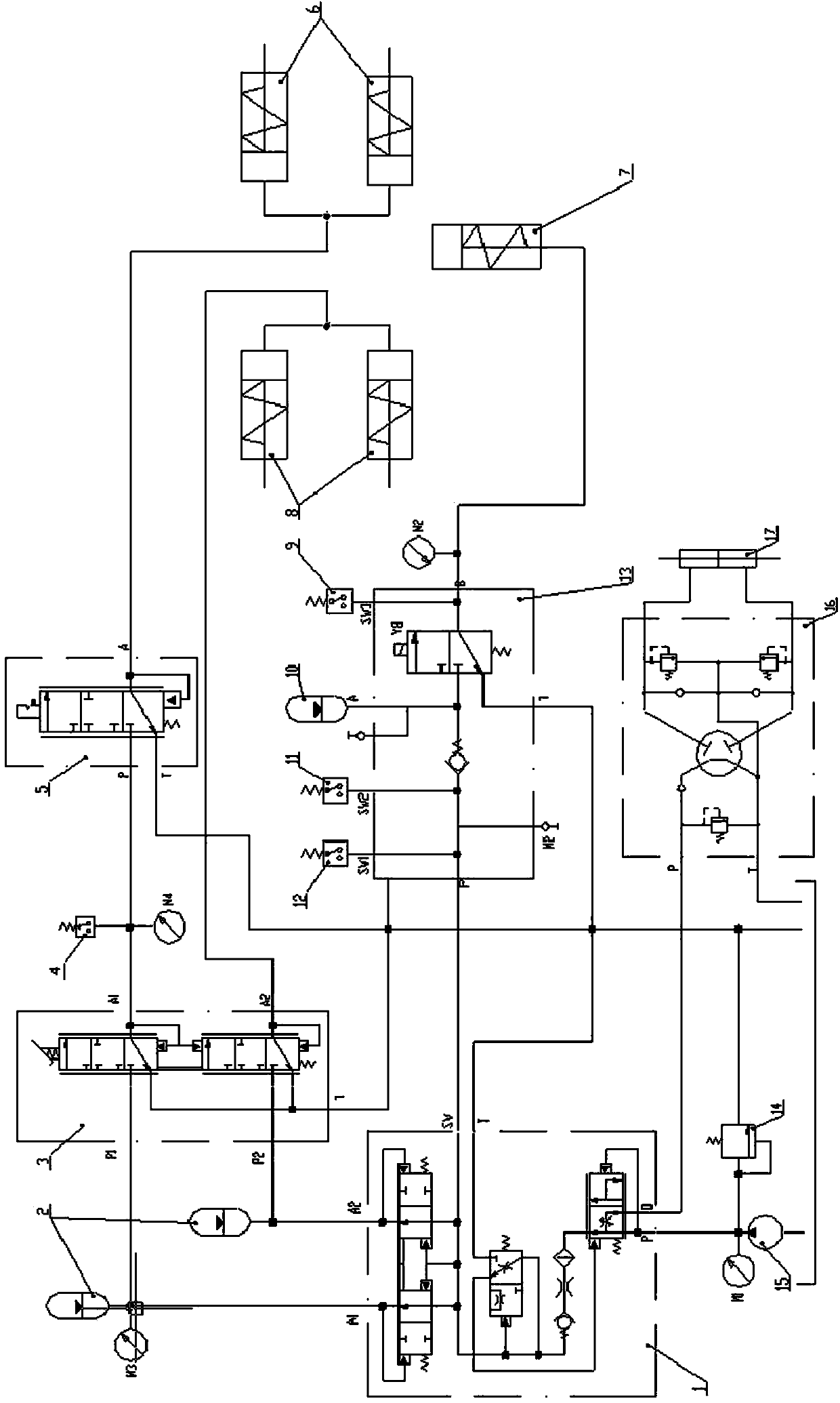

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] like figure 1 Shown: the present invention includes two-way fluid charging valve 1, first accumulator 2, series pedal valve 3, brake tail light pressure switch 4, pressure reducing valve 5, rear axle brake 6, parking brake 7, front axle brake 8 , parking alarm switch 9, second accumulator 10, emergency brake action switch 11, low pressure alarm switch 12, parking and emergency brake valve block 13, overflow valve 14, dual gear pump 15, steering pump 16 and Steering oil cylinder 17; dual gear pump 15 and steering pump 16 are respectively connected to dual charging valve 1, the oil outlet of dual gear pump 15 is connected to port P of dual charging valve 1, and the outlet of dual charging valve 1 A1 port and A2 port are respectively connected to the P1 port and P2 port of the series pedal valve 3 through pipelines, the first accumulator 2 is connected to the pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com