Dredging system and dredging method during boiler coal bin shed coal

A technology of boiler coal and coal bunker loosening machine, which is applied in the field of boiler coal bunker, can solve the problems of power plant production impact, furnace extinguishing accident, long time consumption, etc., and achieves the effects of low operation cost, convenient installation and maintenance, and improved operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

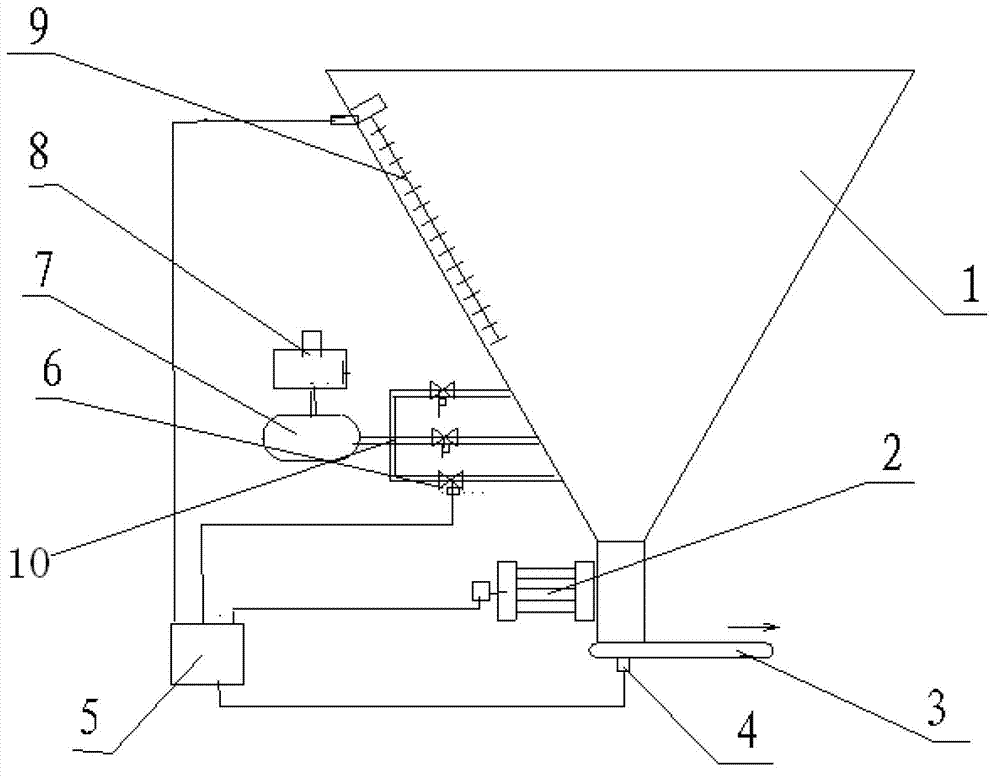

[0012] Such as figure 1 Shown, a kind of dredging system when coal bunker sheds coal of boiler, it is to install rapping motor 2 at the discharge port of coal bin 1, has three holes in the middle and lower part of coal bunker 1, and air guide pipe 10 is installed on the hole, guides The air pipe 10 is connected to the cylinder 7 through the solenoid valve 6, and the cylinder 7 is connected to the air compressor 8. The air guide pipe 10, the solenoid valve 6, the cylinder 7 and the air compressor 8 form a high-pressure gas impact device. When the coal is blocked, the solenoid valve 6 is opened. Use high-pressure airflow to produce point-shaped impact on the coal-blocking place to dredge the coal-blocking. The coal bunker loosening machine 9 is installed on the inner wall of the coal bunker 1, and the coal breaking signal sensor 4 is installed on the belt 3 in front of the furnace. The coal breaking signal sensor 4 is connected to the signal input end of the DCS control system 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com