Formula for viscosity reducer

A technology of viscosity reducer and formula, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of poor salt resistance, short maintenance cycle, narrow application range, etc., to reduce viscosity, improve fluidity, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A formulation of a viscosity reducer, which is formulated from the following components (percentage by weight):

[0027] Industrial grade potassium aluminum sulfate dodecahydrate 35%; Industrial grade sodium hexametaphosphate 28%; Industrial grade sodium bicarbonate 26%; Industrial grade sodium citrate 11%;

[0028] The viscosity reducer of the present invention is prepared by fully mixing the aluminum potassium sulfate, sodium hexametaphosphate, sodium bicarbonate and sodium citrate in the above weight percentage.

[0029] Laboratory preparation of mud: Measure 1000 mL of mud, add 10 grams of bentonite, and stir until uniform. Measure mud viscosity with engineering viscosity test funnel, pH value is 9-10.

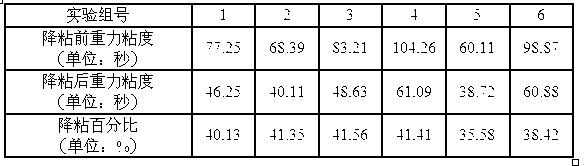

[0030] Measure 700mL of the above mud, add the prepared viscosity reducer to reduce the viscosity of the mud (the weight of the added viscosity reducer is 0.13% of the weight of the mud), stir it evenly, and count the time when 500 mL leaks out, the measured The v...

Embodiment 2

[0034] A formulation of a viscosity reducer, which is formulated from the following components (percentage by weight):

[0035] Industrial grade potassium aluminum sulfate dodecahydrate 35%; Industrial grade sodium hexametaphosphate 25.7%; Industrial grade sodium bicarbonate 25.1%; Industrial grade sodium citrate 14.2%;

[0036] The viscosity reducer of the present invention is prepared by fully mixing the aluminum potassium sulfate, sodium hexametaphosphate, sodium bicarbonate and sodium citrate in the above weight percentage.

[0037] Laboratory preparation of mud: Measure 1000 mL of mud, add 10 grams of bentonite, and stir until uniform. Measure mud viscosity with engineering viscosity test funnel, pH value is 9-10.

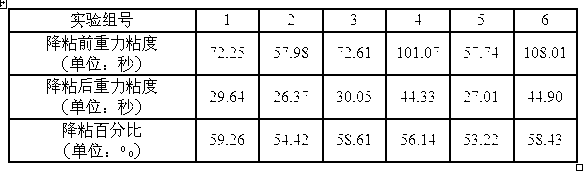

[0038] Measure 700mL of the above mud, add the prepared viscosity reducer to reduce the viscosity of the mud (the weight of the added viscosity reducer is 0.18% of the weight of the mud), stir it evenly, and count the time when 500 mL leaks out, the measured ...

Embodiment 3

[0042] A formulation of a viscosity reducer, which is formulated from the following components (percentage by weight):

[0043] Industrial grade potassium aluminum sulfate dodecahydrate 32.8%; Industrial grade sodium hexametaphosphate 25.2%; Industrial grade sodium bicarbonate 22.4%; Industrial grade sodium citrate 19.6%;

[0044] The viscosity reducer of the present invention is prepared by fully mixing the aluminum potassium sulfate, sodium hexametaphosphate, sodium bicarbonate and sodium citrate in the above weight percentage.

[0045] Laboratory preparation of mud: Measure 1000 mL of mud, add 10 grams of bentonite, and stir until uniform. Measure mud viscosity with engineering viscosity test funnel, pH value is 9-10.

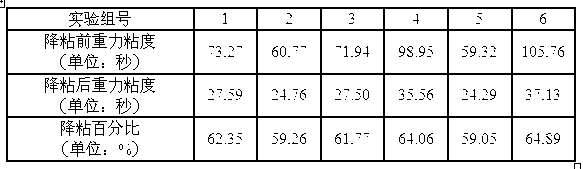

[0046] Measure 700mL of the above-mentioned mud, add the prepared viscosity reducer to reduce the viscosity of the mud (the weight of the added viscosity reducer is 0.23% of the weight of the mud), stir it evenly, and count the time when 500 mL leaks out, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com