Liquid crystal compound containing isothiocyanic acid radical as well as preparation method and application thereof

A compound, liquid crystal technology, applied in chemical instruments and methods, organic chemistry, liquid crystal materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

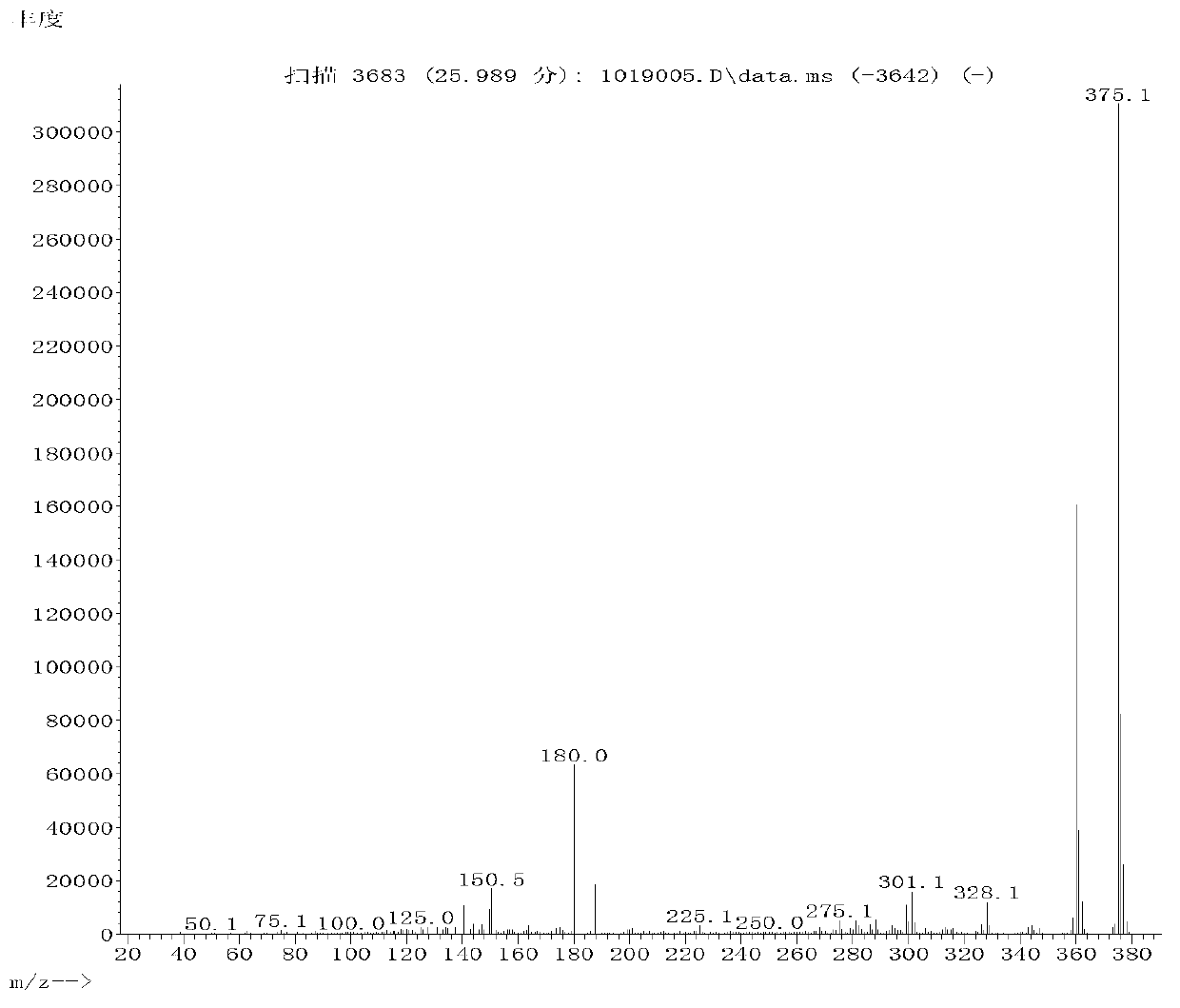

Examples

Embodiment 1

[0090] preparation of

[0091] Step 1) a, preparation of p-iodonitrobiphenyl

[0092]

[0093] Add 254g (1mol) of biphenyl (solvent) and 280g (1.1mol) of iodine particles (reactant) into a 1L three-necked bottle, and add 200ml of concentrated nitric acid (reactant) with a mass percentage concentration of 68% dropwise at about 70°C ), keep the reaction temperature between 65°C and 75°C, when red gas appears during the reaction, import it into an alkali bottle to remove it, after the dropwise addition, cool down to about 40°C, add 40ml of dichloromethane (solvent), heat to reflux again, reflux 4h, the reaction is complete, lowered to room temperature, filtered to obtain a brown solid, 500ml of deionized water (solvent) to wash the filter cake, after draining, add 500ml of toluene (solvent) to boil the solid for about 30min, let it cool, filter, and dry to obtain yellow 322g of solid product, GC: 92.4%, yield 91.5%.

[0094] b, the preparation of p-iodoaminobiphenyl

[00...

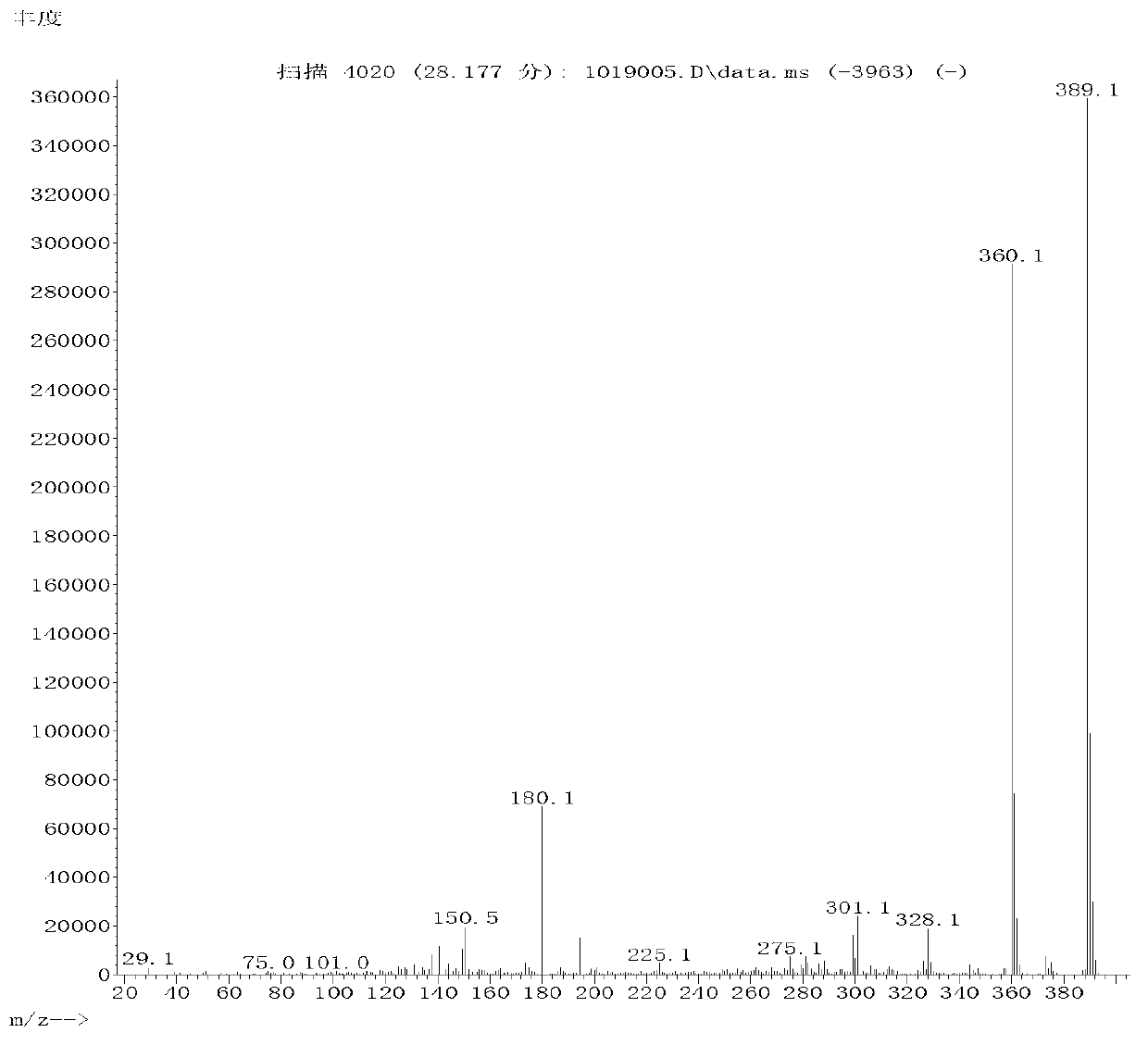

Embodiment 2

[0123] preparation of

[0124] Step 1) Prepare p-iodoaminobiphenylacetylene according to the same steps as in Example 1

[0125] Step 2) Preparation of 4-iodo-3,5-difluoropropylbenzene:

[0126]

[0127] Add 27g (0.173mol) of 3,5-difluoropropylbenzene (reactant) and 100ml of dried THF (solvent) into a 250ml three-necked flask. mol) n-butyllithium (2.5M) (solvent), keep the temperature at -70--80°C, after the dropwise addition, keep the reaction at low temperature for 30min, then dropwise add 53.5g of iodine (0.21mol) (reactant) 50ml of THF (solvent) solution, keep at -70--80°C, after the dropwise addition, raise the temperature naturally, add 50ml of saturated sodium bisulfite (reducing agent) aqueous solution at about 0°C for hydrolysis, separate the liquids, take the upper organic phase, and remove it by rotary evaporation Solvent, 46g (0.155mol) of the product light yellow liquid was obtained, GC: 95.1%, yield: 89.7%, set aside.

[0128] Step 3) Preparation of 4'-((...

Embodiment 3-4

[0140] Referring to Example 1 in this example, replace 3,5-difluoroethylbenzene in step 4 with 3,5-difluorobutylbenzene and 3,5-difluoropentylbenzene respectively, and other operations are the same as in Example 1 , to prepare the following compounds.

[0141]

[0142] The physical properties of liquid crystal monomers 1-3 and 1-4 were tested, and the following results were obtained:

[0143] Table 2 Liquid crystal application property data of liquid crystal monomer

[0144]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com