Multi-functional quickly-constructed house die room plate structure system and construction method thereof

A multi-functional, panel-structured technology, applied in formwork/formwork/work frame, building structure, and on-site preparation of building components, can solve problems such as increased labor and auxiliary material costs, not portable, and unsatisfactory solar energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] The present invention will be described in further detail below in conjunction with the examples in the accompanying drawings, but the examples are only used as preferred illustrations and do not limit the protection scope of the present invention.

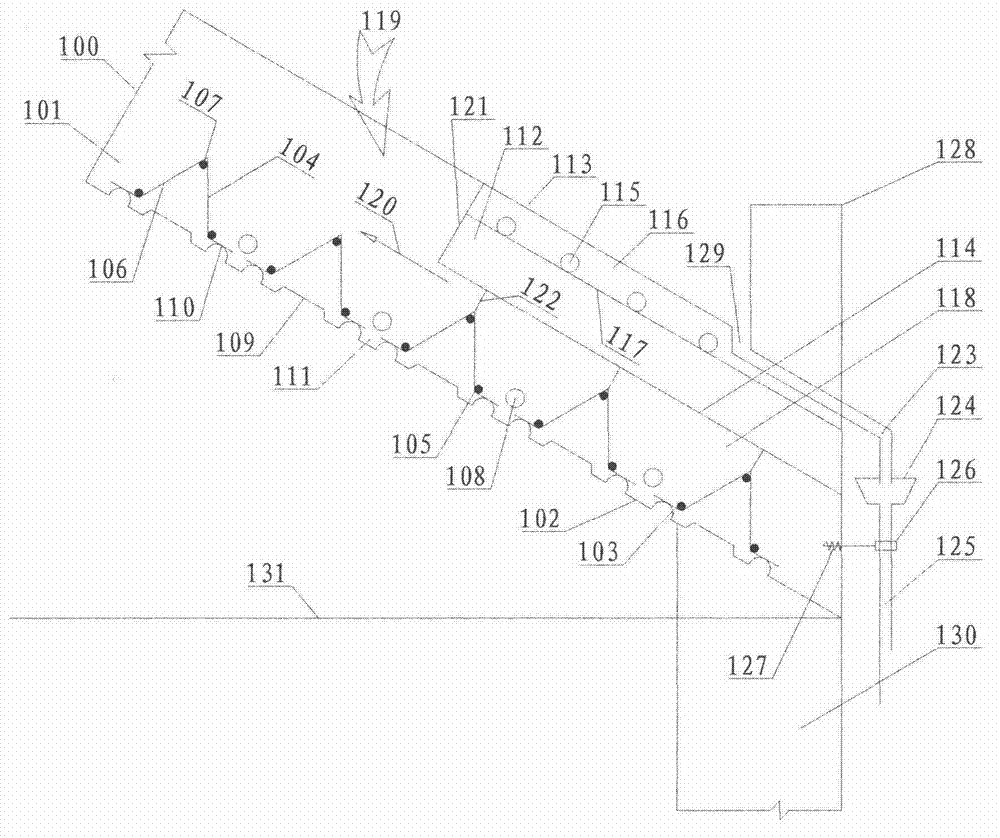

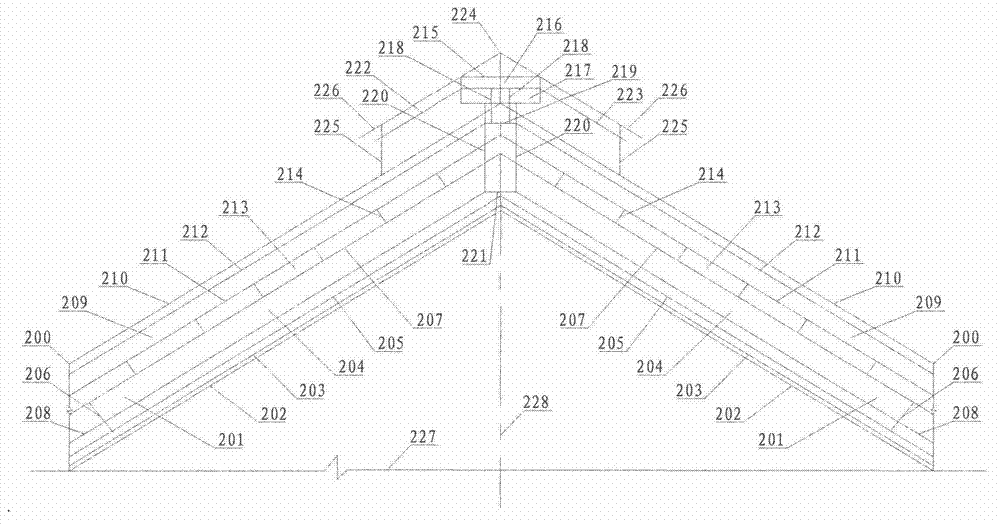

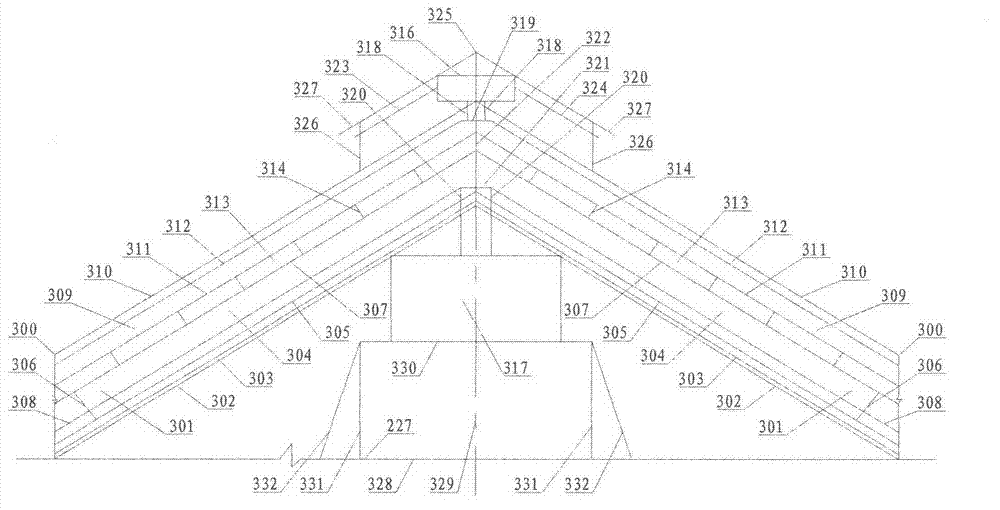

[0099] see figure 1 , figure 2 , image 3 , the technical scheme that the present invention can provide is implemented like this: the purpose is to provide a kind of multi-functional fast house-building formwork roof structure system and construction method thereof; Described a kind of multifunctional rapid house-building formwork roof structure system, Specifically by:

[0100] First use the improved formwork slab as the base plate 101 / 201 / 301 of the formwork slab, and install various required functional pipes 108 / 208 / 308 and binding upper / lower distribution steel bars on the base plate 101 / 201 / 301, install The fixed support connecting rod 122 / 214 / 314 perpendicular to the base plate, and the panel 112 / 209 / 309 of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com