Stirring friction diffusion welding method used for connection of dissimilar materials

A friction stir, dissimilar material technology, applied in welding equipment, non-electric welding equipment, edge parts of workpieces, etc., can solve the problem of high cost, achieve the effect of low cost, high quality combination, and reduce preparation quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention provides a friction stir diffusion welding method for connecting aluminum alloy and stainless steel, comprising the following steps:

[0035] A. Ni powder and Cu powder are mixed uniformly, are prepared into spraying liquid, adopt the mode of thermal spraying to spray described spraying liquid onto the welding face of described stainless steel plate 2, form the Ni-Cu coating that thickness is 100 μm, described Ni-Cu coating as the intermediate layer material of aluminum alloy and stainless steel3;

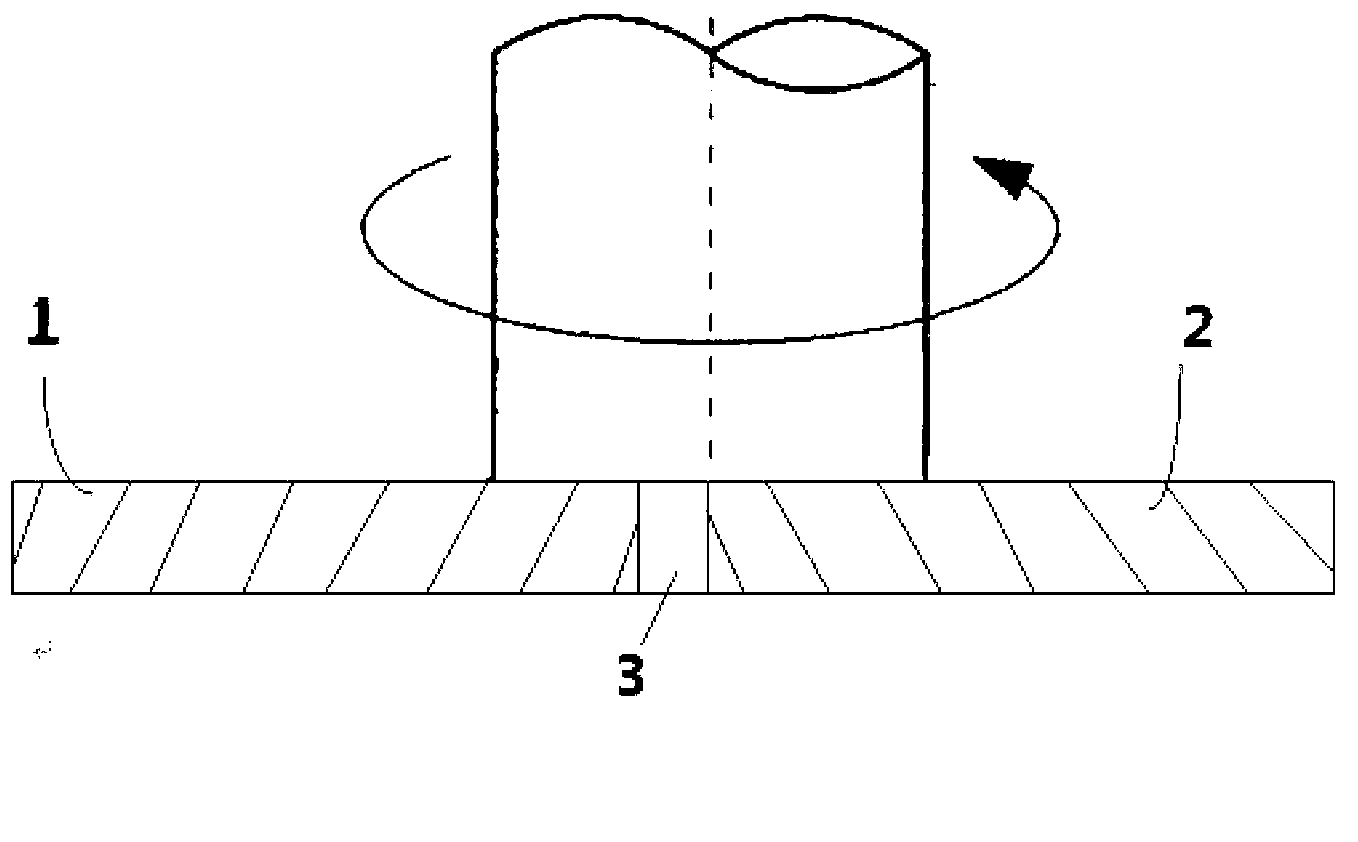

[0036] B. Put together the stainless steel plate 2 and the aluminum alloy plate 1 through step A to form a butt joint, see figure 1 ;

[0037] C. Rotate the stirring head and insert it into the joint to be welded, and generate heat by friction with the joint to be welded, and keep it warm for a period of time. Composition changes to carry out isothermal solidification and composition diffusion and homogenization, and finally form a joint of continuous metallu...

Embodiment 2

[0043] This embodiment provides a friction stir diffusion welding method for connecting aluminum plates and stainless steel plates and includes the following steps:

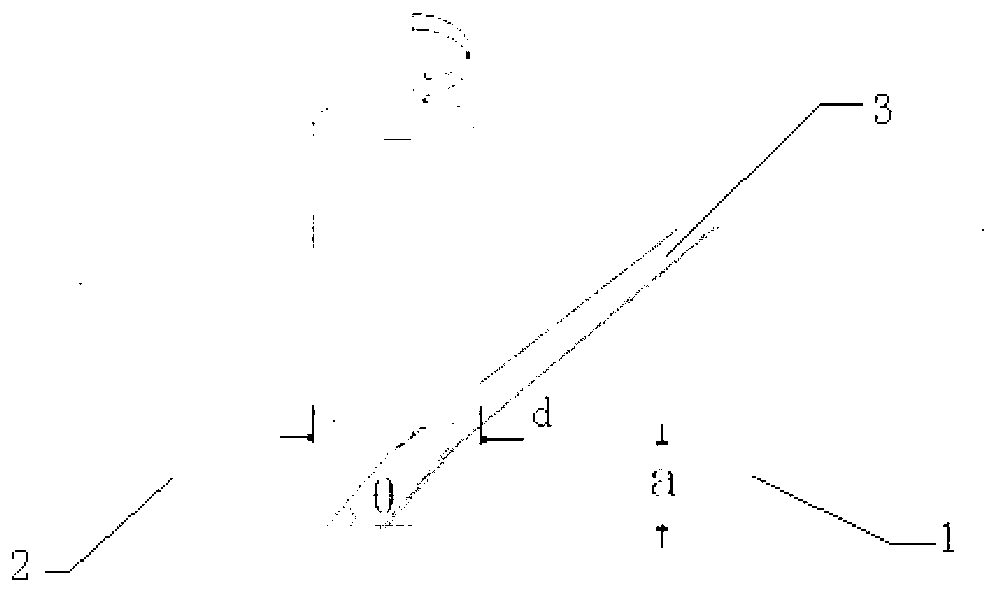

[0044] A. The stainless steel plate 2 and the aluminum plate 1 are combined to form a horizontal lap joint, and the aluminum plate 1 and the stainless steel 2

[0045] Each has an inclined horizontal lap interface, the horizontal inclination angle θ of the horizontal lap interface of the aluminum base material and the horizontal inclination angle of the horizontal lap interface of the stainless steel base material are complementary angles to each other, and the two pass through the lap interface mated to form the horizontal lap joint, see figure 2 ;

[0046]B. Add a metal sheet made of nickel between the aluminum plate 1 and the stainless steel plate 2 as a middle

[0047] The interlayer substance 3, the thickness of the interlayer substance 3 is 700 μm;

[0048] C. Rotate the stirring head and insert it i...

Embodiment 3

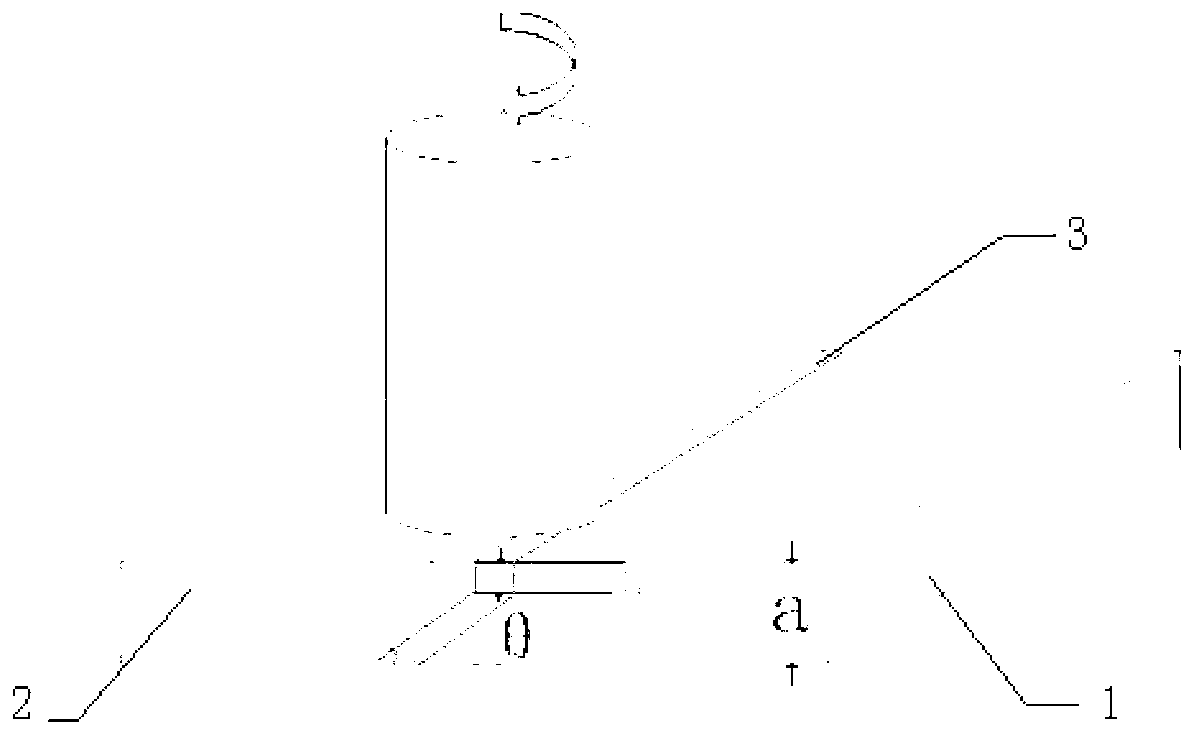

[0054] This embodiment provides a friction stir diffusion welding method for connecting an aluminum plate and a titanium plate, comprising the following steps:

[0055] A. The titanium plate 2 and the aluminum plate 1 are put together to form a horizontal lap joint, and the aluminum plate 1 and the titanium plate 2 respectively have an inclined horizontal lap interface and a vertical lap with a height h on the horizontal lap interface interface, the horizontal inclination angle θ of the horizontal lap interface of the aluminum plate 1 and the horizontal inclination angle of the horizontal lap interface of the titanium plate 2 are complementary angles, and the two form the horizontal lap joint after cooperating through the lap interface connector, see image 3 ;

[0056] B. Adding a metal foil made of nickel as an intermediate layer between the aluminum plate 1 and the titanium plate 2

[0057] Substance 3, here, the intermediate layer substance 3 can also be added in the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com