Method for recycling gold and cyanides in surface treatment wet-process cleaning solution

A surface treatment and cleaning solution technology, applied in the direction of metal cyanide, simple alkali metal cyanide, chemical instruments and methods, etc., can solve the problems of expensive operation of recycling equipment, inability to further reduce manufacturing costs, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in more detail below with reference to the drawings and reference symbols, so that those skilled in the art can implement it after studying this specification.

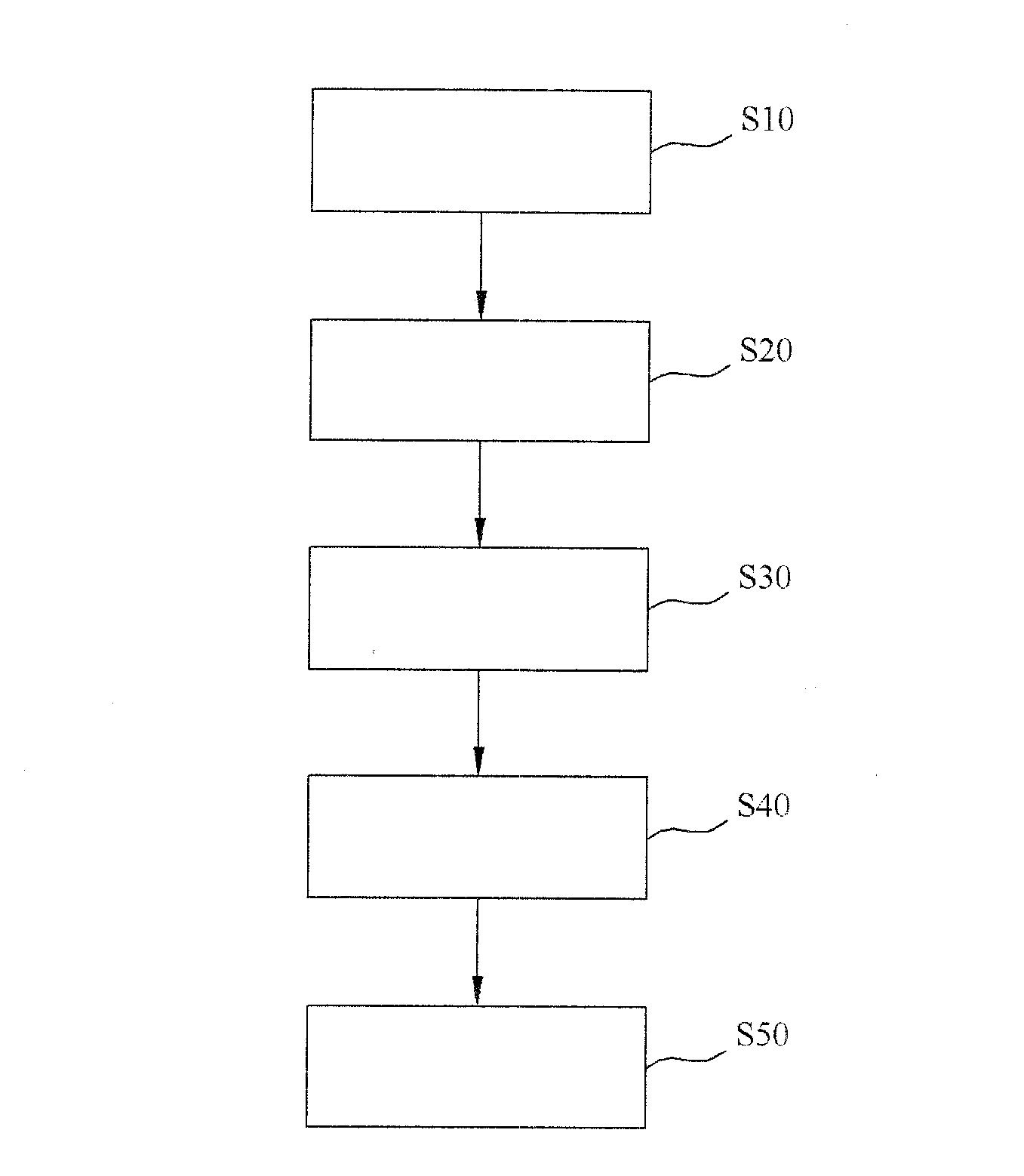

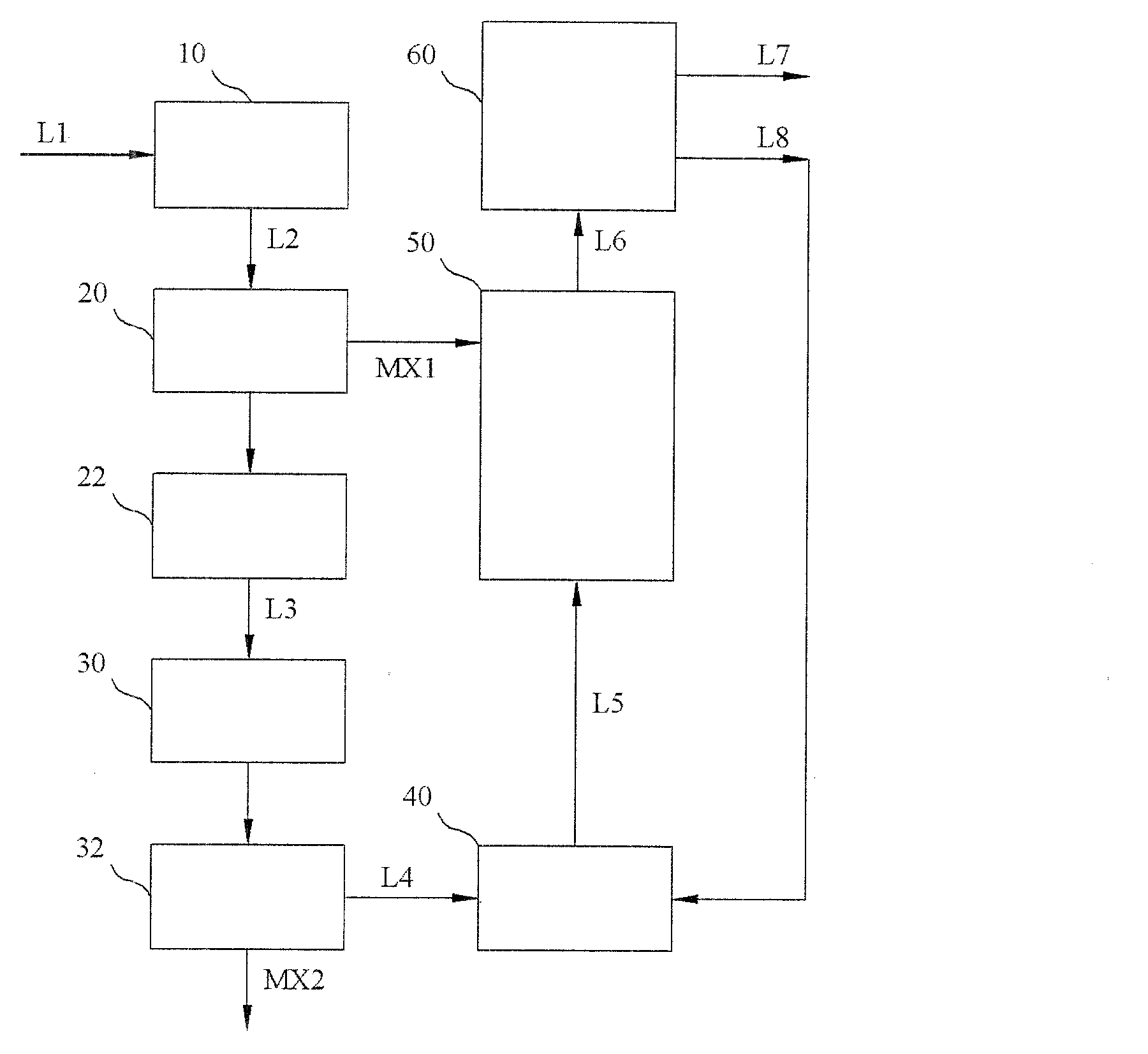

[0018] refer to figure 1 The recycling method of gold and cyanide in the surface treatment wet process cleaning solution of the present invention includes steps S10, S20, S30, S40 and S50, for respectively carrying out gold-containing slurry collection treatment, gold separation treatment, calcium borate separation treatment, gold Dissolving treatment and reverse osmosis separation treatment, so as to recover the gold contained in the plating solution or cleaning solution in the surface treatment process, wherein the plating solution or cleaning solution may further contain at least solid impurities, organic impurities, boric acid, citric acid, potassium cyanide, Any one of potassium hydroxide and heavy metal impurities, which may include nickel or c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com