Intercalation polymer gel diversion agent

A technology of polymer and diverting agent, applied in drilling composition, production fluid, wellbore/well components, etc., can solve the problems that restrict the large-scale application and popularization of diverting technology, high sensitivity and high cost, and achieve improvement Water injection profile, improved sweep efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

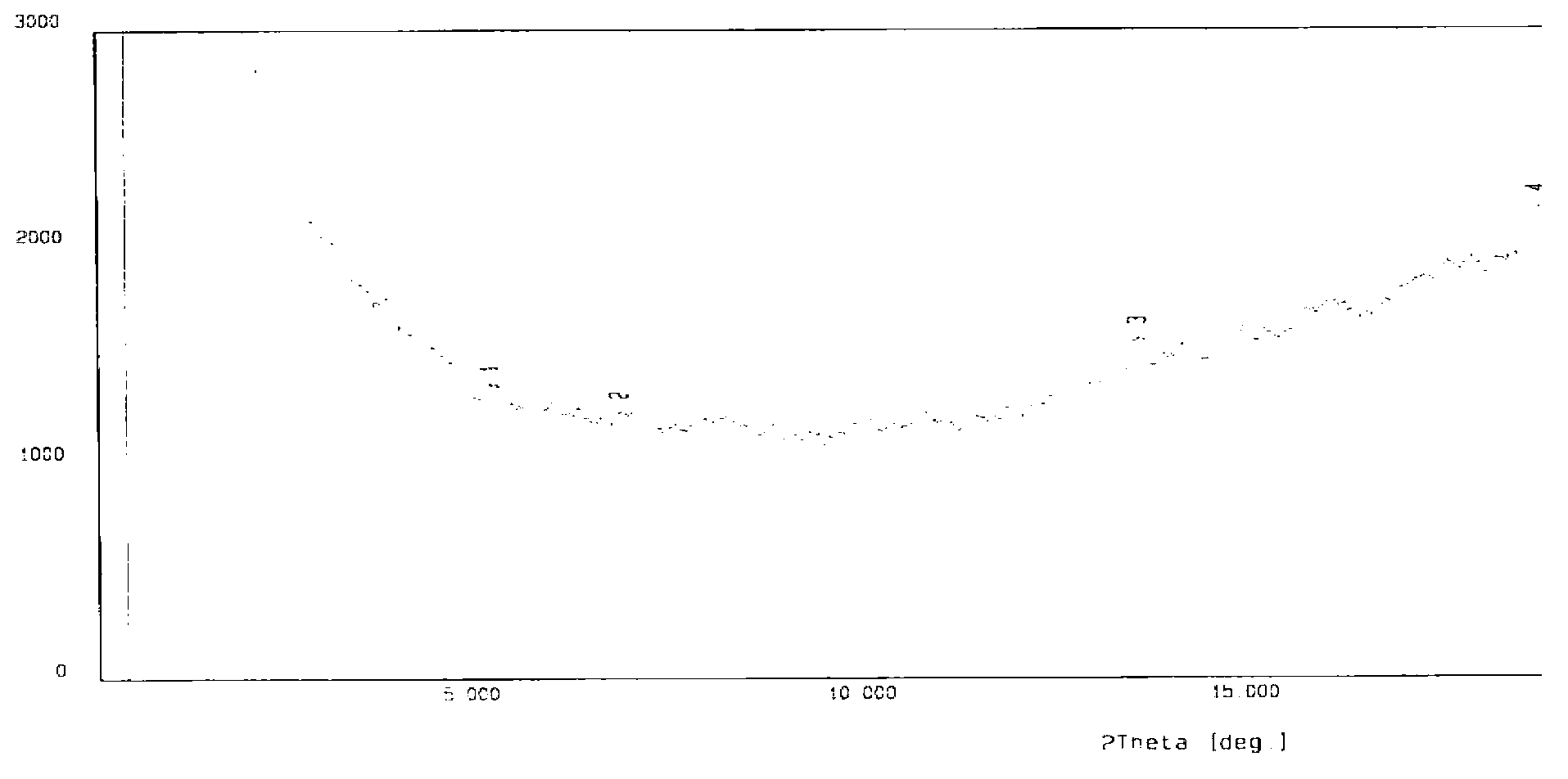

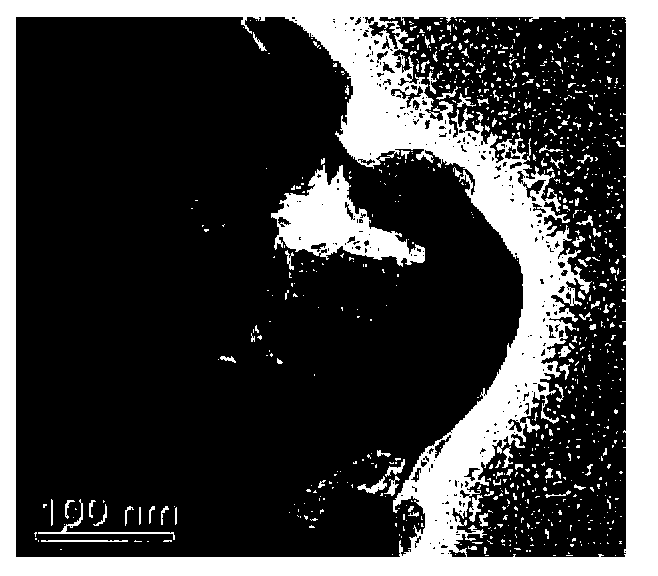

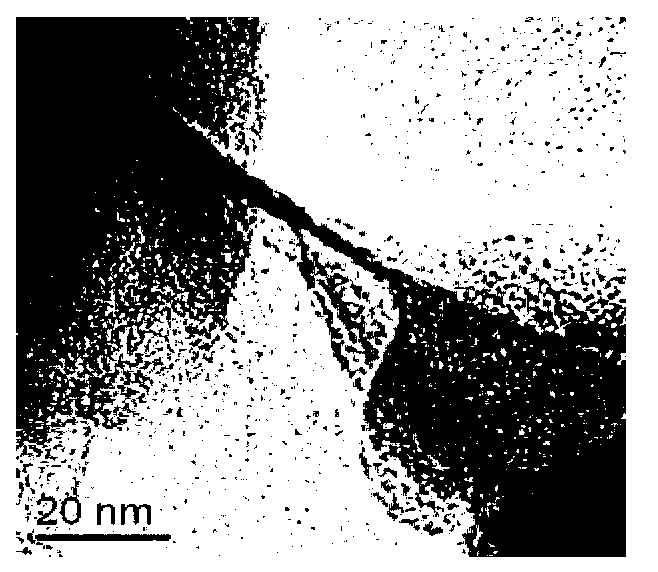

Image

Examples

preparation example Construction

[0029] The preparation method of intercalated polymer gel diverting agent is as follows:

[0030] 1. Preparation of intercalation polymer aqueous solution

[0031] Because the molecular weight of the intercalation polymer is relatively high, the intercalation polymer solution with a concentration of 1wt% should be prepared at first for use: when preparing, first weigh 10g of the intercalation polymer, and then measure 1000ml of simulated brine. Under stirring, gradually add the intercalation polymer to the simulated brine to dissolve it, and obtain the intercalation polymer solution for use; it should be noted that the prepared intercalation polymer solution must be matured for 24 hours before use.

[0032] 2. Preparation of crosslinking agent solution

[0033] Prepare a cross-linking agent aqueous solution with a concentration of 10wt%. When preparing, weigh 1g of chromium lactate, 1g of chromium acetate, and 1g of an alkaline cross-linking agent, mix them with 10ml of water...

Embodiment 1

[0049] This embodiment provides a kind of intercalation polymer gel steering agent, which is prepared through the following steps:

[0050] Add 20 parts of acrylamide, 1 part of modified inorganic clay mineral, and 78.8 parts of deionized water into a four-necked bottle, blow nitrogen gas at 12°C for 30 minutes, add 0.2 parts of initiator, and polymerize to obtain an intercalation polymer, wherein, The initiator is made up of ammonium persulfate and sodium sulfite, and the weight ratio of ammonium persulfate to sodium sulfite is 1.5:1;

[0051] Add 0.15 parts of intercalation polymer, 0.1 part of cross-linking agent chromium acetate, 0.005 part of regulator oxalic acid (oxalic acid is used to adjust the pH value of the intercalation polymer gel system, control the gelation time, and can be added according to the length of gelation time Appropriate amount of oxalic acid) was added to 100 parts of Daqing Oilfield simulated brine, stirred at high speed (1000 rpm) for 120 minutes ...

Embodiment 2

[0054] This embodiment provides a kind of intercalation polymer gel steering agent, which is prepared through the following steps:

[0055] Add 23 parts of acrylamide, 2 parts of modified inorganic clay minerals, and 74.8 parts of deionized water into a four-necked bottle, blow nitrogen gas at 12°C for 30 minutes, add 0.2 parts of initiator, and copolymerize to obtain an intercalation polymer. Among them, The initiator is made up of ammonium persulfate and sodium sulfite, and the weight ratio of ammonium persulfate to sodium sulfite is 1.8:1;

[0056] Add 0.2 parts of intercalation polymer, 0.10 part of cross-linking agent chromium acetate, and 0.01 part of regulator oxalic acid to 100 parts of Daqing Oilfield simulated brine, and stir at high speed (1000 rpm) for 120 minutes to obtain intercalation polymer gel steering Agent 2A (viscoelastic weak gel diverting agent), or add 0.2 parts of intercalation polymer and 0.19 parts of basic crosslinking agent to 100 parts of Daqing O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com