Efficient and energy-saving asphalt concrete stirring system

A technology of asphalt concrete and mixing system, which is applied in roads, road repairs, roads, etc., and can solve problems such as insufficient combustion, high fuel and gas costs, and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the invention.

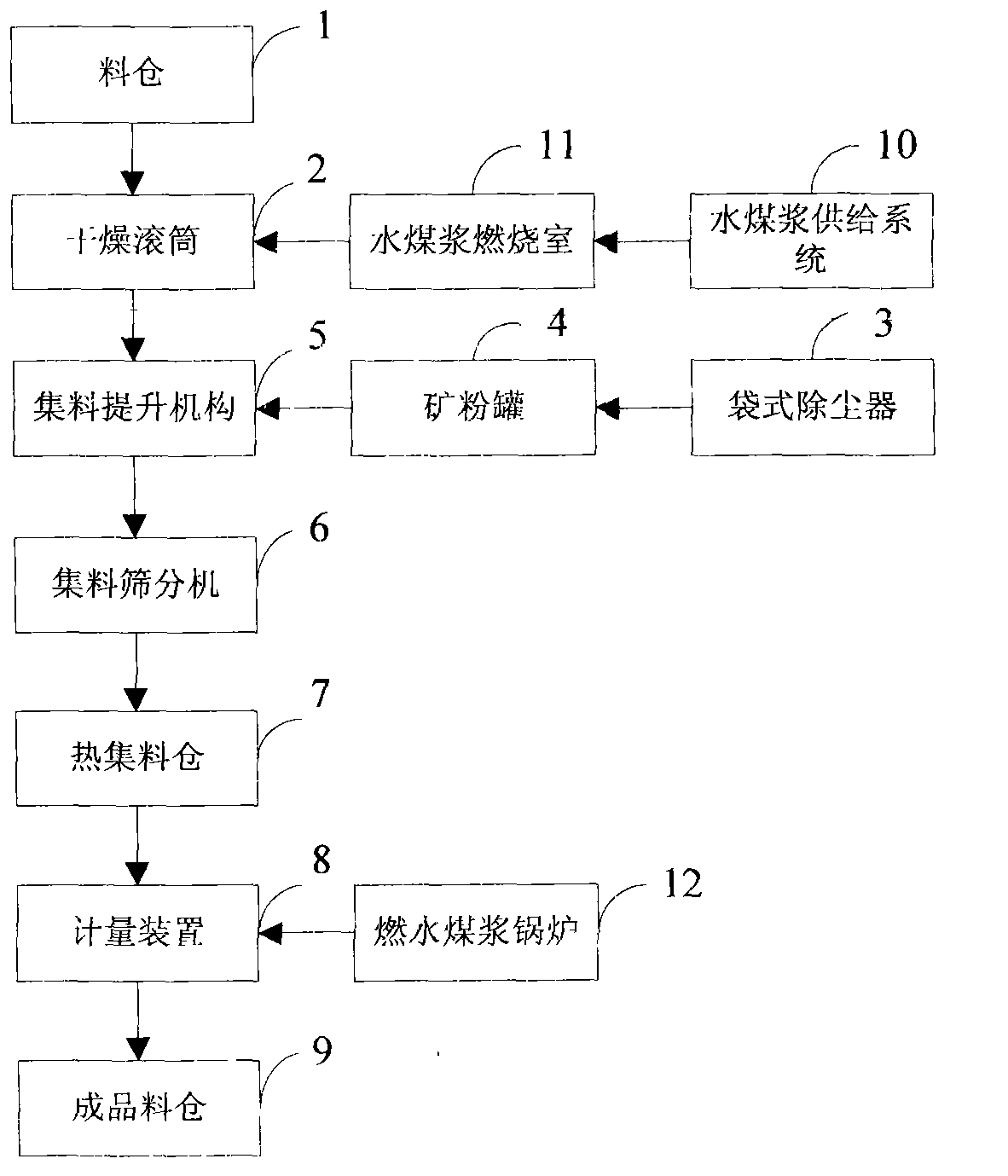

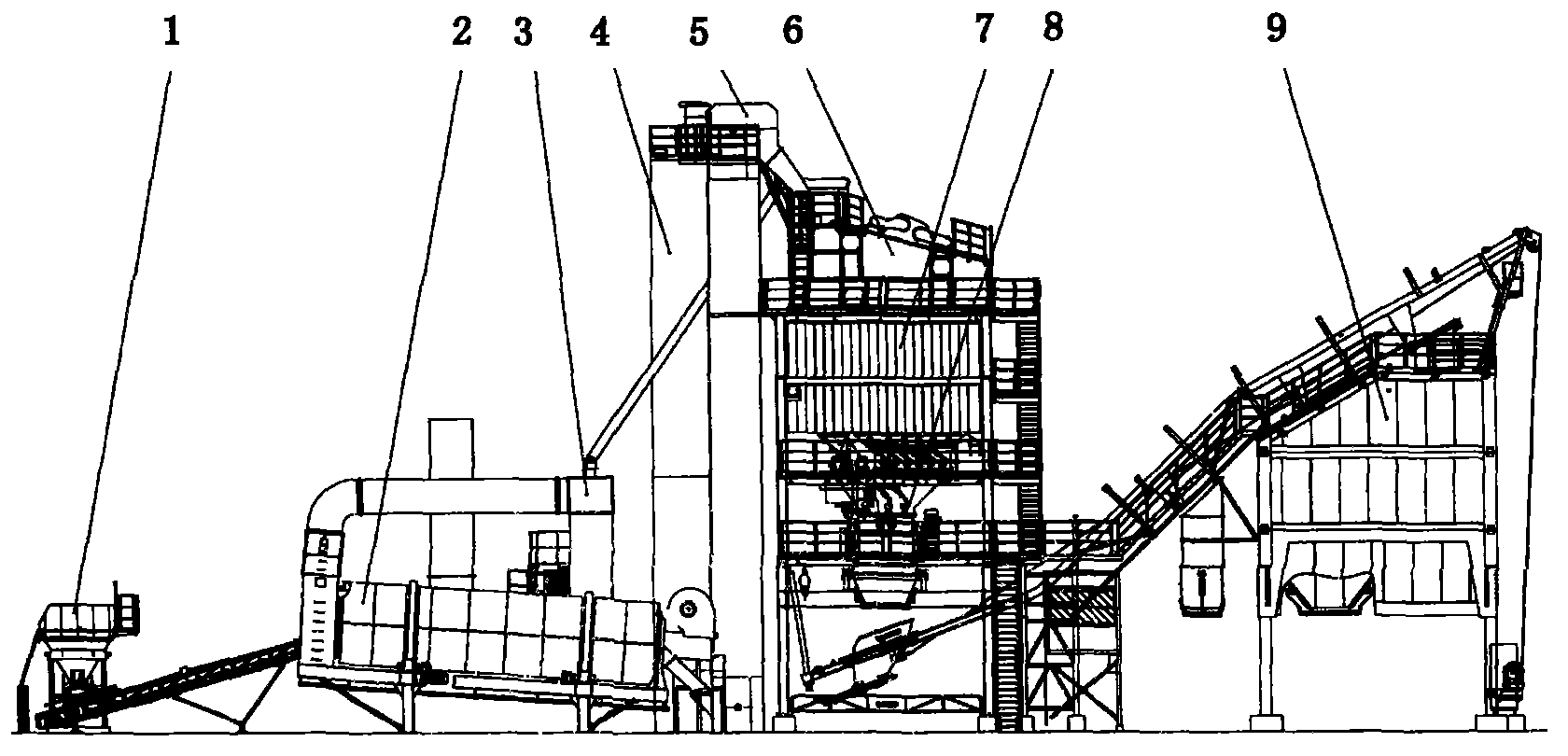

[0023] figure 1 and figure 2 The structure of the high-efficiency and energy-saving asphalt concrete mixing system provided by the embodiment of the present invention is shown. For ease of illustration, only the parts relevant to the present invention are shown.

[0024] The asphalt concrete mixing system includes: silo 1, drying drum 2, bag filter 3, mineral powder tank 4, aggregate lifting mechanism 5, aggregate screening machine 6, heat aggregate silo 7, metering device 8, finished material Warehouse 9, CWS supply system 10, CWS combustion chamber 11, CWS boiler 12;

[0025] The silo 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com