Tester for oilfield eccentric separate injection well and long-time real-time working condition monitoring method

A technology of eccentric water distribution and monitoring instrument, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., which can solve the problem of not being able to control and improve the injection quality well, not being able to provide data on the injection quality, and not being able to obtain points Variation of water injection volume with time in separate layers of injection wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in conjunction with the accompanying drawings.

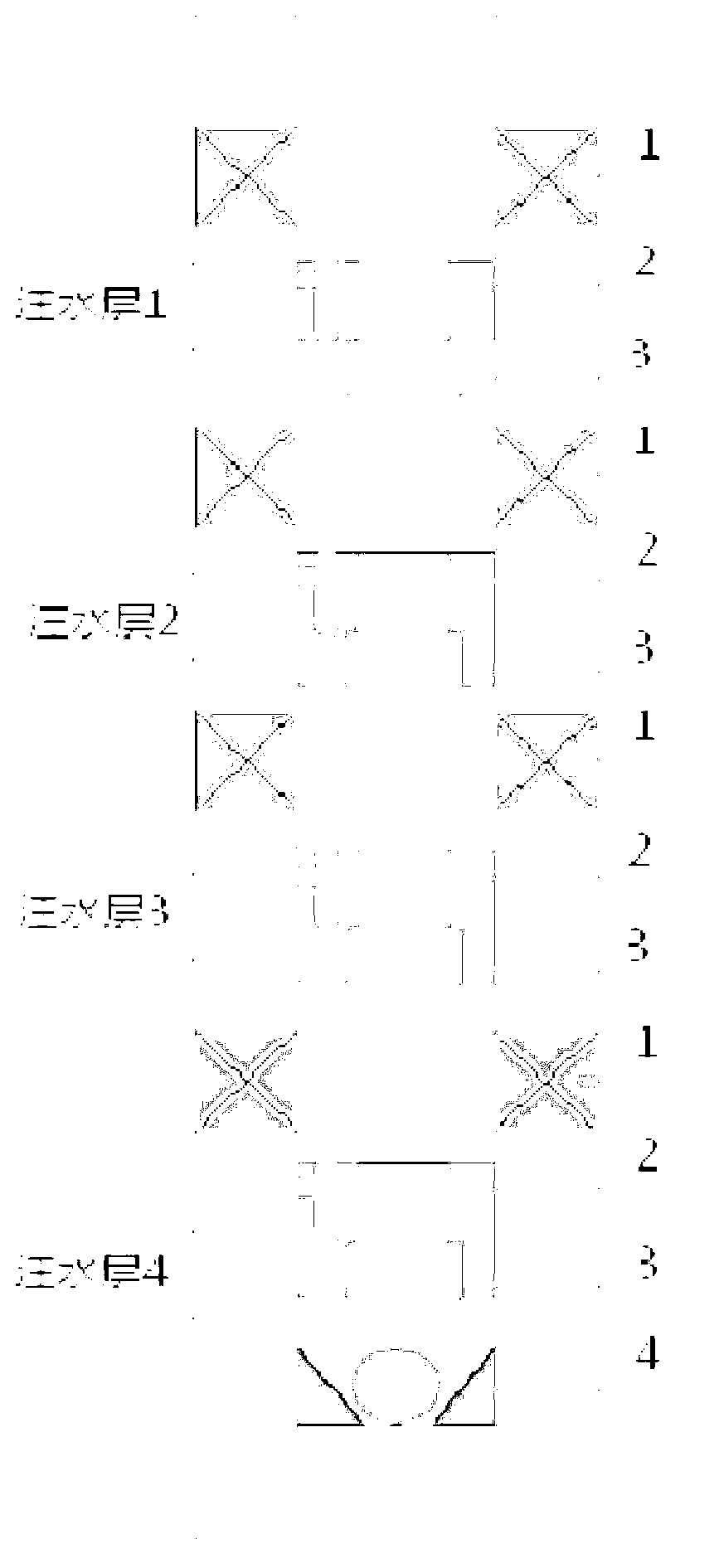

[0033] The eccentric water distribution pipe string with the long-term real-time monitoring instrument for the working conditions of eccentric layered water injection wells is as follows: figure 1 As shown, the packer 1, the eccentric water distributor 2, the monitor 3, and the one-way valve 4 are lowered to a predetermined depth through the oil pipe connection, and after pressing and setting, layered water injection is realized;

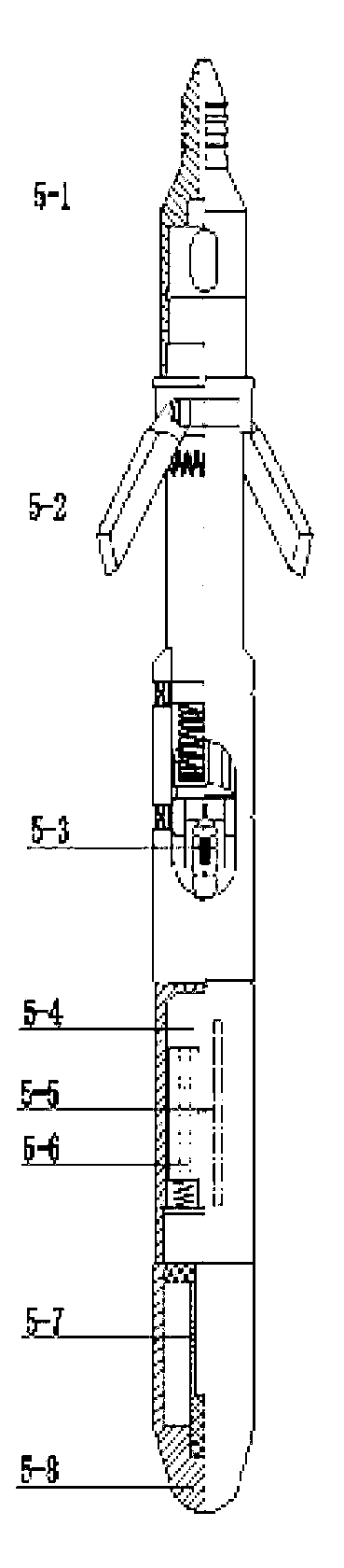

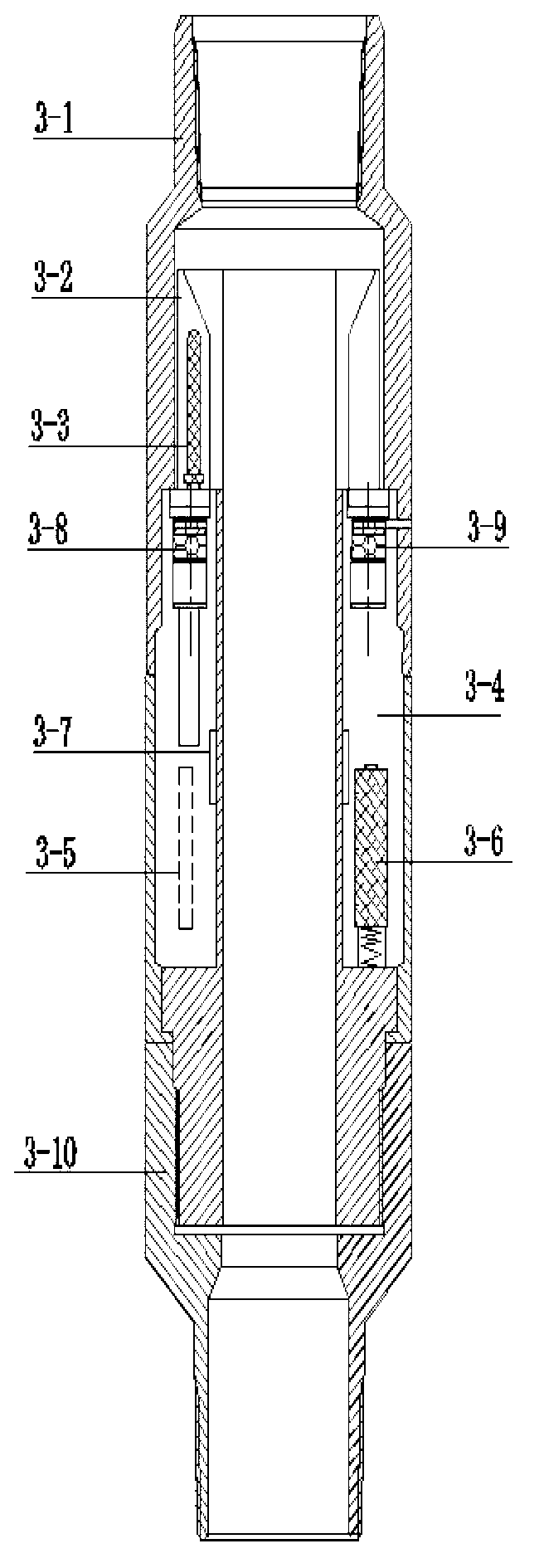

[0034] Such as image 3 , Figure 5 As shown, the monitor 3 is composed of an upper connector 3-1, a housing, an antenna protective cover 3-2, an antenna 3-3, a circuit compartment 3-4, a circuit board 3-5, a high temperature battery pack 3-6, and a load sensor 3 -7. Two pressure sensors (3-8, 3-9) and lower joint 3-10 are formed. The upper joint 3-1 and the lower joint 3-10 are respectively installed at both ends of the housing. The upper joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com