Wind driven generator

A wind turbine and wind wheel technology, applied in wind turbine components, wind engines, wind power generation, etc., can solve the problems of unfavorable large-scale production, increase in engineering volume, transportation volume, and cost reduction, so as to save rent and The cost of road construction, the safety of working at heights, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

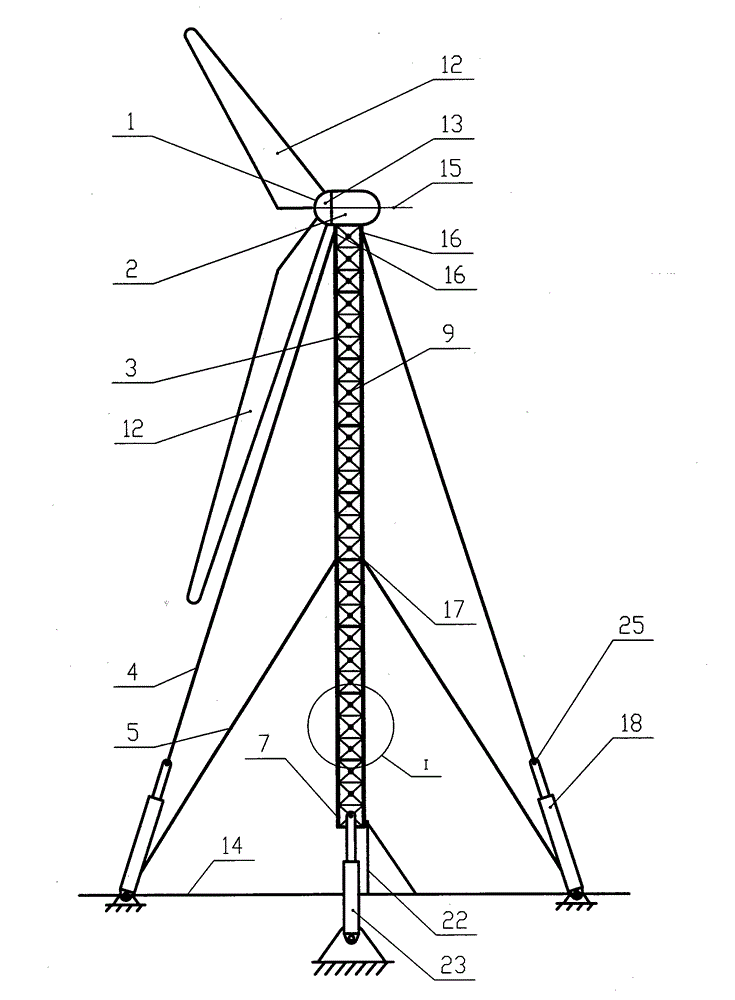

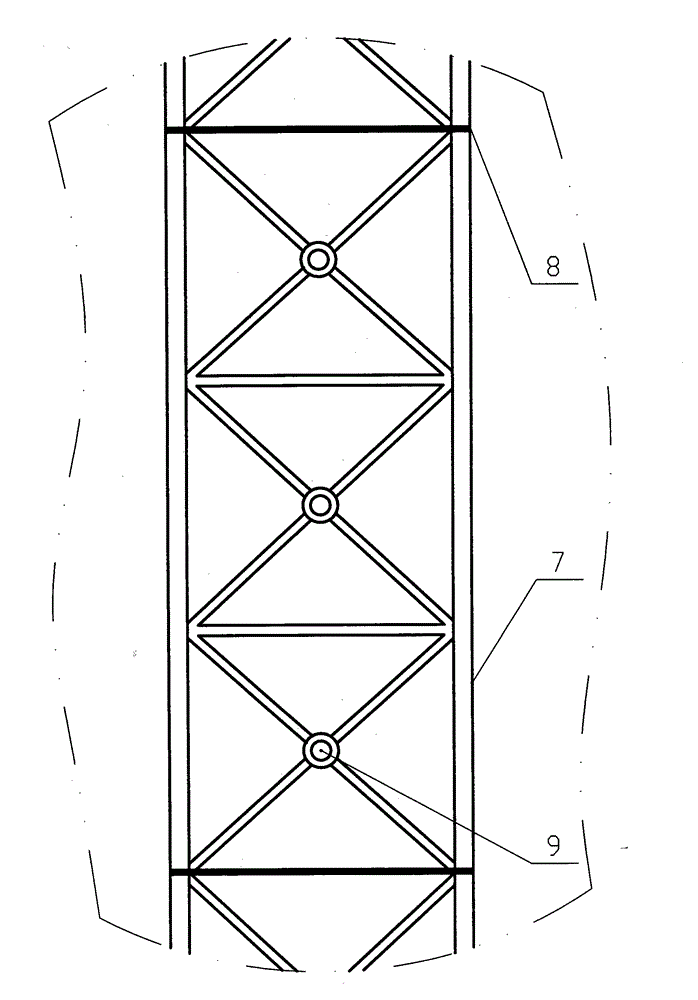

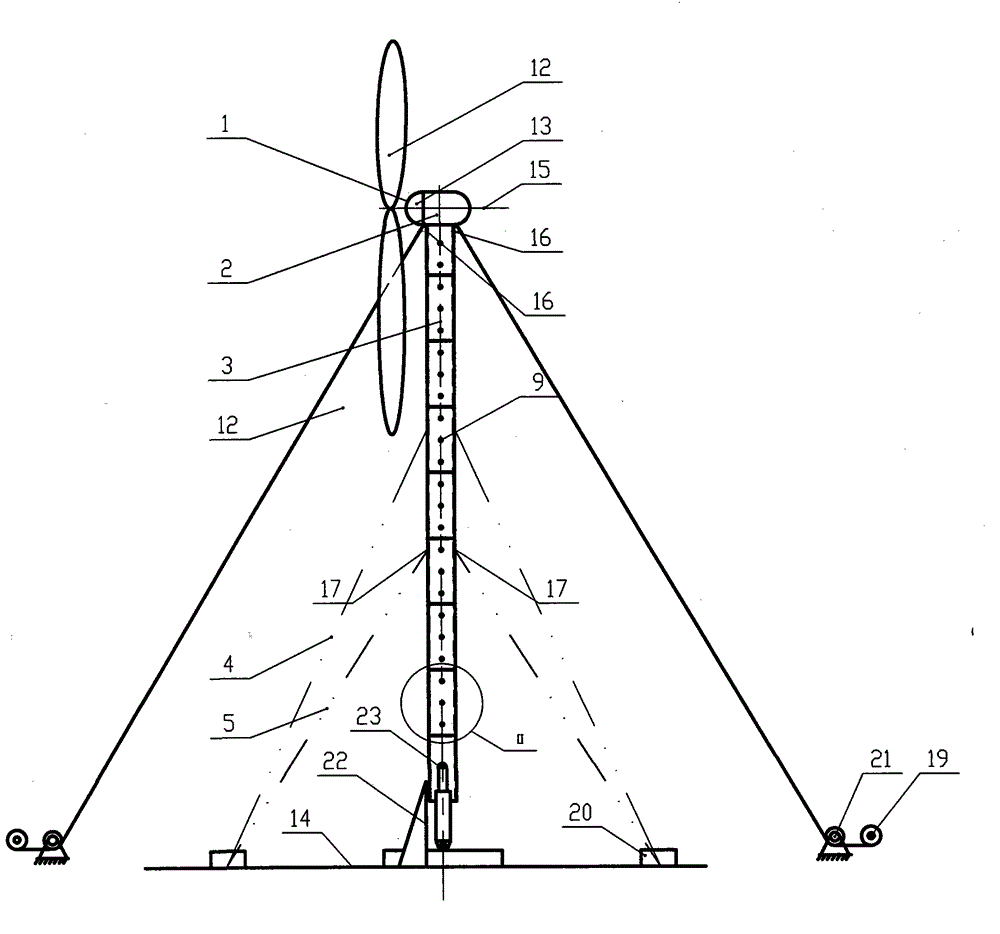

[0027] combine figure 1 and figure 2 , the first embodiment of a wind power generator in the present invention includes a wind rotor 1 formed by installing each blade 12 on a hub 13, and some types of wind rotors 1 are also equipped with a pitch control device. In the first embodiment, the blades 12 are inclined to the outside, and the blades 12 form an angle of 72° with the center line 15 of the horizontal axis; the tower 3 of the truss structure is disassembled into a tower subsection 7 that can be installed from the top first, and the tower The frame puppet 7 is connected to the adjacent tower puppet through the puppet end face 8; the engine room assembly part 2 including the power generation system and various auxiliary systems; Between the cable connector 16 and the foundation 14 figure 1 In the middle, the upper drag cable 4 is connected with the oil cylinder 18 to form the anti-fall device 25, which is the working state in the installation process; the lower drag cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com