Cut-off filter for frustrating wavelength shift

A technology of cut-off filtering and wavelength drift, applied in optics, optical components, instruments, etc., can solve the problems of large mechanical stress, easy adhesion failure, poor chemical stability, etc., to achieve low manufacturing yield, suppression of wavelength drift, chemical performance poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

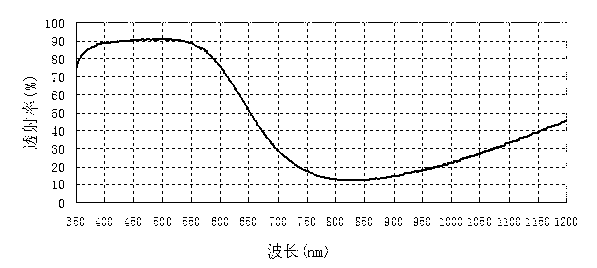

[0029] figure 1 It is the transmission spectrum curve of the blue glass substrate (model QB51) of the existing cut-off filter. like figure 1 As shown, the blue glass substrate not only has a poor steepness in the transmission-cut transition region, but also has a poor cut-off in the infrared region, so its thickness needs to be increased to 0.5mm. However, even if it is compared, its steepness can only barely meet the requirements of use (such as figure 1 shown), and the efficacy of blocking infrared light and ultraviolet light must rely on cut-off filters to complete.

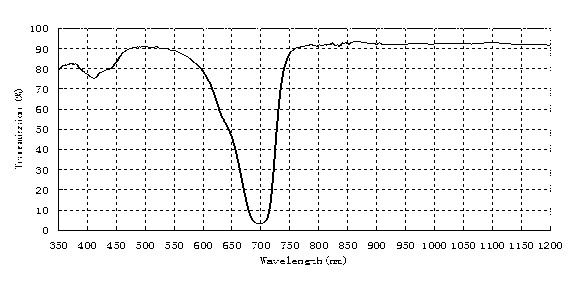

[0030] figure 2 It is the transmission spectrum curve of the blue plastic substrate (model FLXL100AA) of the existing cut-off filter. figure 2 Although the blue plastic substrate shown is only 0.1mm thick, the steepness of the transmission-cutoff transition region is relatively figure 1The blue glass substrate shown is a marked improvement. However, the disadvantage is that compared with the blue glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com