Moving-coil loudspeaker with area-alterable capacitive vibration sensor

A dynamic speaker and vibration sensor technology, applied in the field of speakers, can solve problems such as unsatisfactory output linearity, complex phase relationship, too deep feedback, etc., achieve compact structure, reduce the lower limit of playback frequency, and have little external influence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

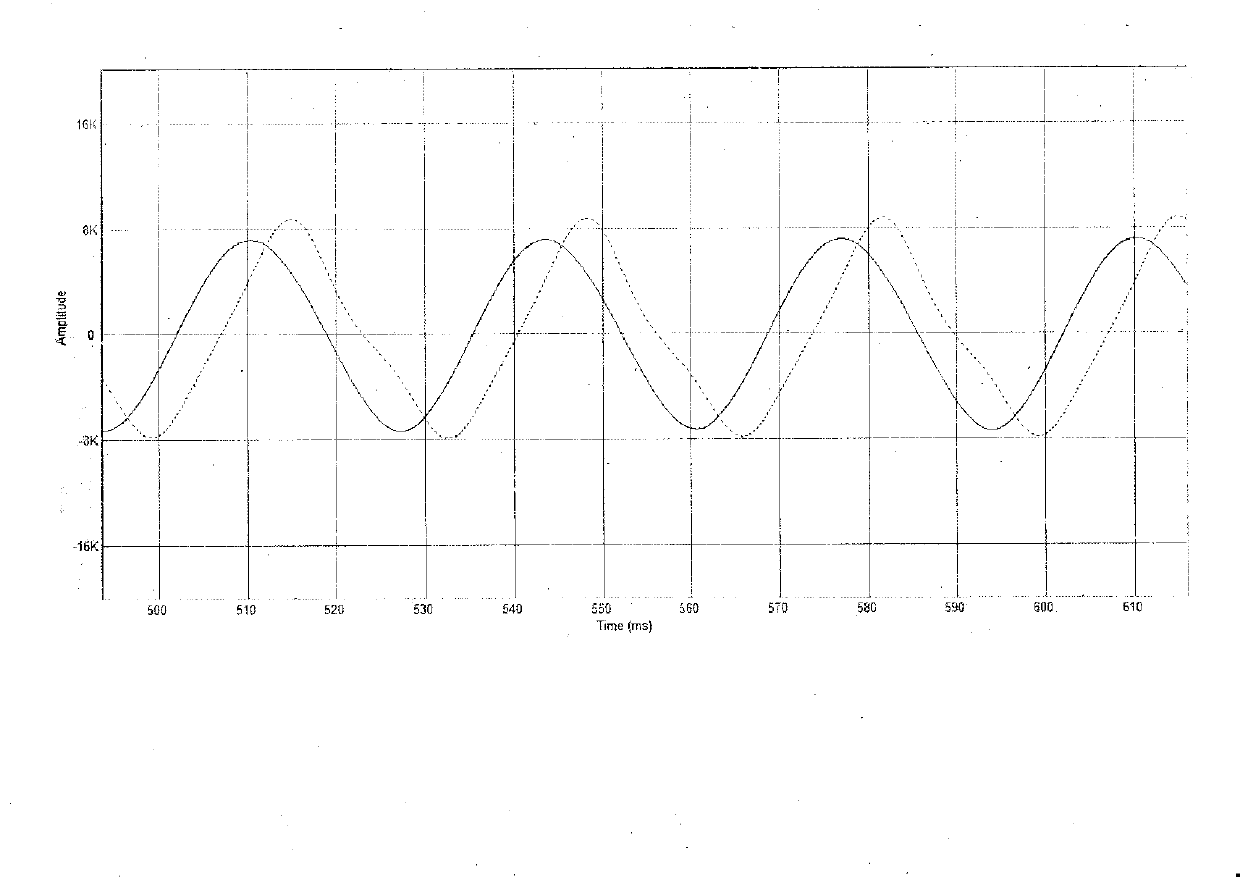

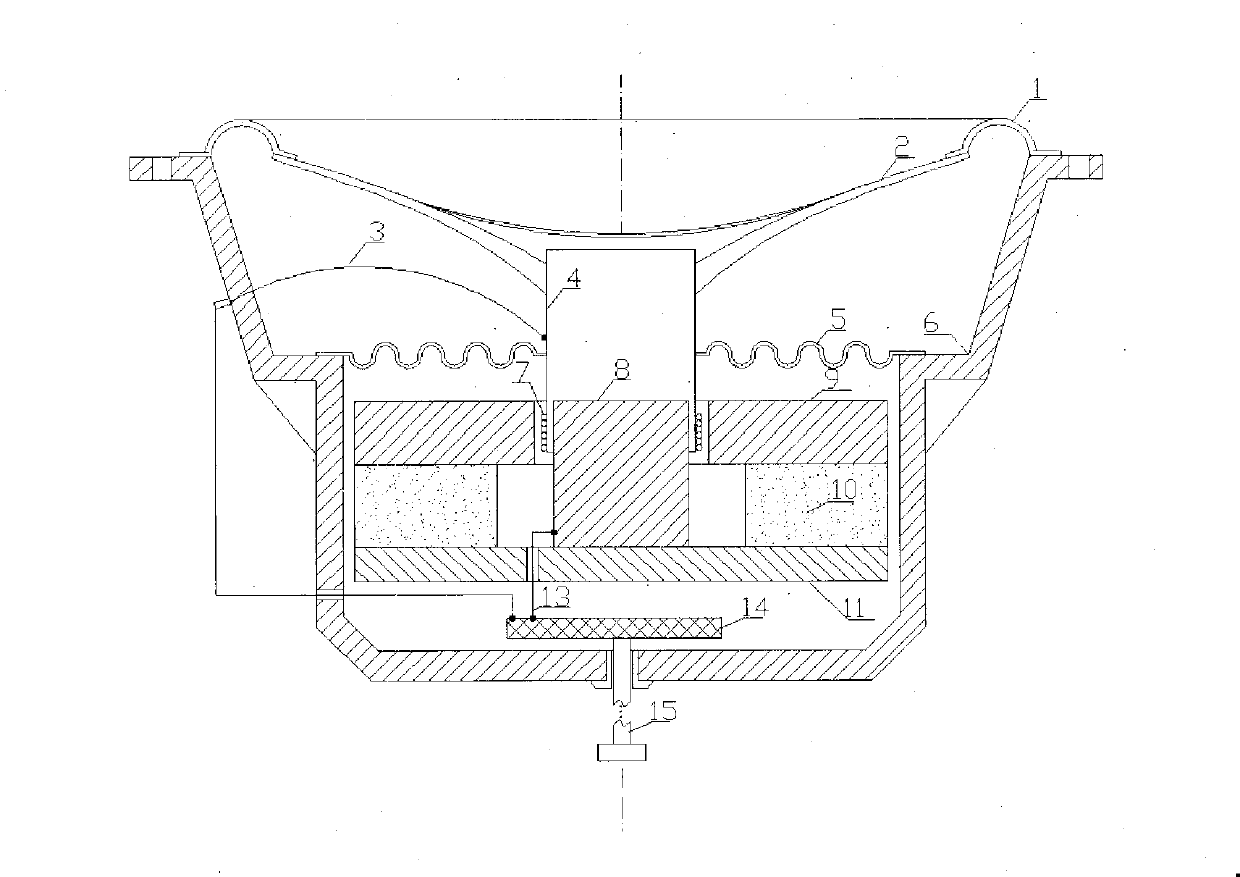

[0049] see figure 1 As shown, a dynamic speaker with a variable area capacitive vibration sensor is composed of a ring 1, a diaphragm 2, a centering piece 5, a basin frame 6, a conductive voice coil skeleton 4, a coil 7, and a magnetic column 8 , a magnetic upper plate 9, a permanent magnet 10, a magnetic lower plate 11, and a capacitance / motion signal conversion circuit 14. Between the magnetic column 8 and the magnetic upper plate 9, there is a . A variable-area capacitive vibration sensor 24 for measuring the displacement of the voice coil. The capacitance variable output by the variable-area capacitive vibration sensor 24 is input to the input terminal of the capacitance / motion signal conversion circuit 14 . The conductive voice coil bobbin 4 can be made of a metal sheet or an organic sheet coated with a conductive layer on the surface. This embodiment is a loudspeaker with an external magnetic circuit, the conductive voice coil bobbin 4 and the outer cylinder of the magn...

Embodiment 2

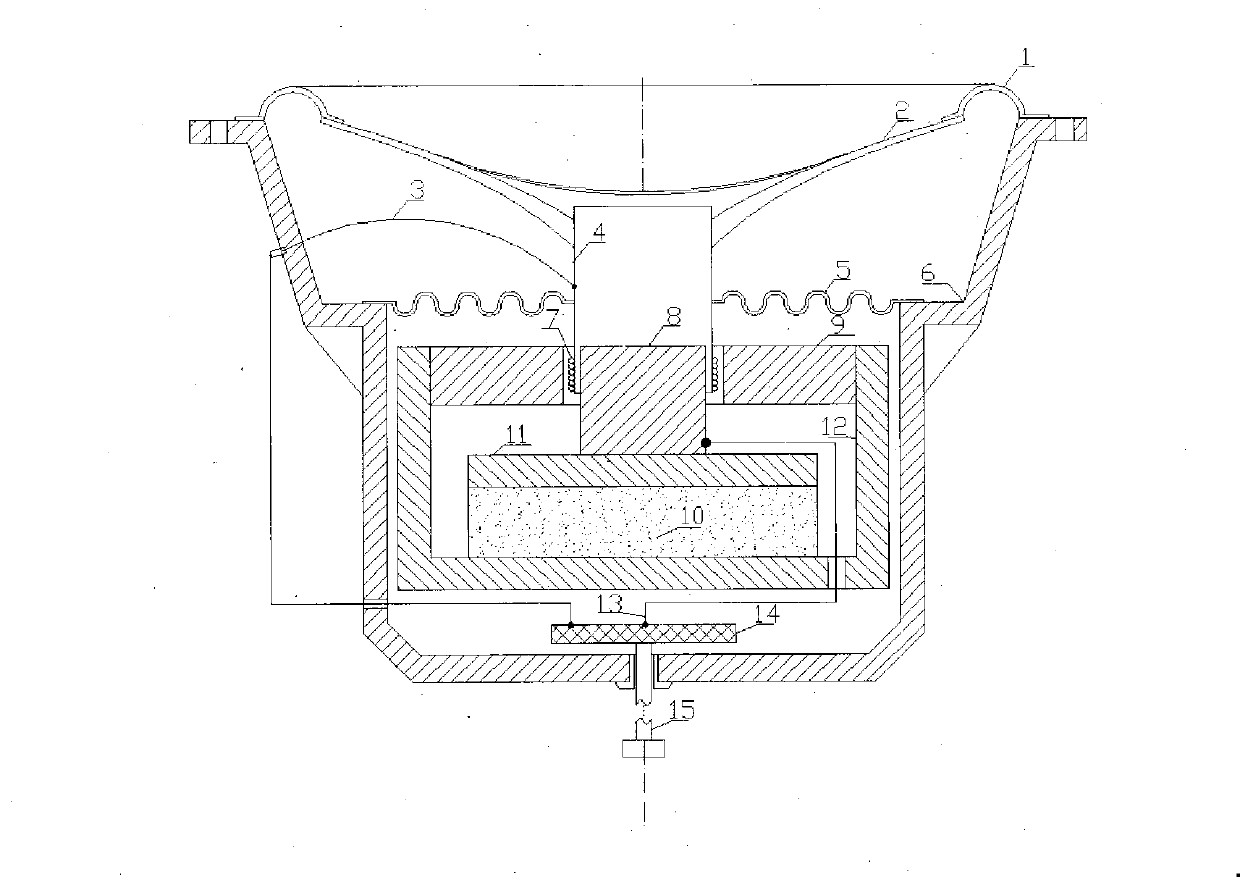

[0051] see figure 2 As shown, this embodiment is a loudspeaker with an internal magnetic axial magnetic circuit, and this kind of loudspeaker is provided with a magnetically conductive bowl 12 . Except that the structure of the magnetic circuit is different, the others are the same as the embodiment 1. During application, an insulating layer is generally inserted into one of the contact surfaces between the magnetically conductive column 8, the magnetically conductive lower plate 11, the permanent magnet 10, and the magnetically conductive bowl 12, and the magnetically conductive upper plate 9 and the magnetically conductive bowl 12 are grounded. , the highest signal-to-noise ratio can be obtained.

[0052] Some internal magnetic magnetic circuit speakers do not seem to have a magnetic upper plate 9. In fact, this design only expands the inner hole of the magnetic upper plate 9 to coincide with the outer diameter of the magnetic upper plate 9. At this time, the magnetic bowl...

Embodiment 3

[0056] see image 3 As shown, the present embodiment is a loudspeaker with an external magnetic magnetic circuit, and a straight cylindrical inner electrode 16 is fixedly installed on the outer surface of the magnetic conductive column 8, and the conductive voice coil bobbin 4 and the straight cylindrical inner electrode 16 constitute a variable area capacitive vibration sensor 24 , the conductive voice coil bobbin 4 and the straight cylindrical inner electrode 16 are respectively connected to the input terminal of the capacitance / motion signal conversion circuit 14 through the first conductive lead 3 and the second conductive lead 13 . In order to obtain a sufficiently large linear output amplitude, the axial length of the straight cylindrical inner electrode 16 should be such that the voice coil does not exceed the upper and lower edges of the straight cylindrical inner electrode 16 when the voice coil moves with the maximum amplitude. In order to prevent the thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com