Optical Adhesive Sheet

An adhesive sheet, optical technology, applied in the direction of adhesive type, ester copolymer adhesive, film/sheet adhesive, etc., can solve problems such as misoperation and achieve the effect of preventing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

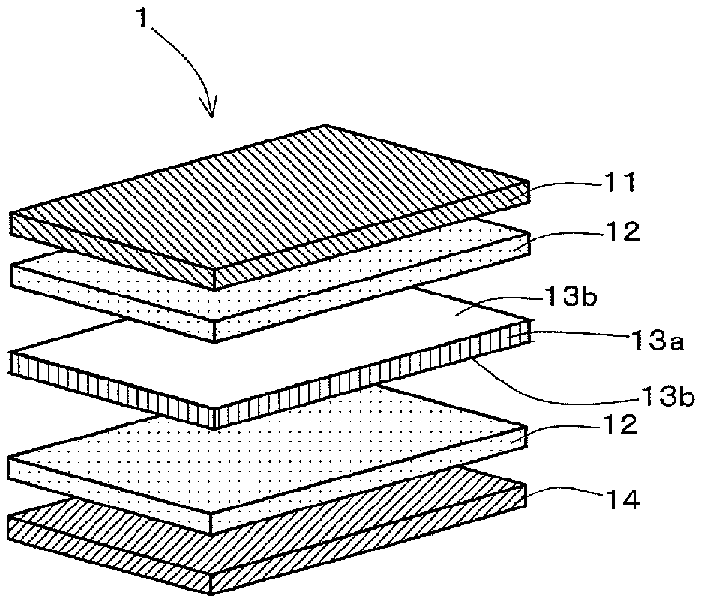

Image

Examples

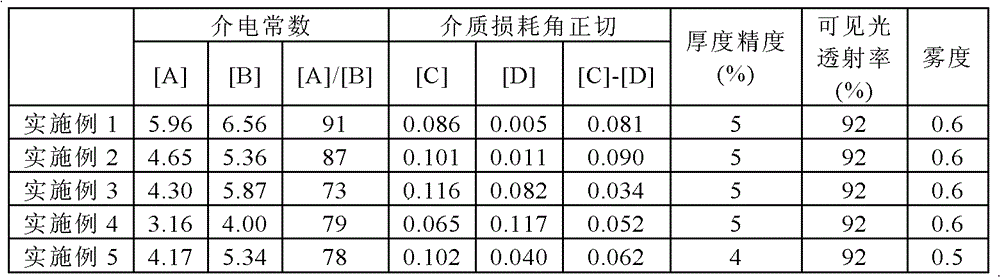

Embodiment 1

[0097] (Preparation of photopolymerizable composition)

[0098] 40 parts by weight of 2-ethylhexyl acrylate, 59 parts by weight of 2-methoxyethyl acrylate, 1 part by weight of 4-hydroxybutyl acrylate, 0.05 parts by weight of 2,2-dimethoxy-1 , 2-diphenyl-1-ketone (trade name "Irugakuyua 651", manufactured by Ciba Corporation of Japan) and 0.05 parts by weight of 1-hydroxycyclohexyl-phenyl ketone (trade name "Irugakuyua 184", manufactured by Ciba Corporation of Japan ) into a four-necked flask, and carried out partial photopolymerization by exposing to ultraviolet rays under a nitrogen atmosphere, thereby obtaining a partial polymer (monomer slurry) with a polymerization rate of 10%.

[0099] After adding 0.1 part by weight of an isocyanate compound (trade name "Corone-to L", manufactured by Nippon Polyurethane Industry Co., Ltd., solid content ratio: 75% by weight) in terms of solid content to 100 parts by weight of this part of the polymer, it was uniformly mixed. Mix to prep...

Embodiment 2

[0103] (Preparation of photopolymerizable composition)

[0104] 69 parts by weight of 2-ethylhexyl acrylate, 30 parts by weight of 2-methoxyethyl acrylate, 1 part by weight of 4-hydroxybutyl acrylate, 3 parts by weight of acrylic acid, 0.05 parts by weight of 2,2-di Methoxy-1,2-diphenyl-1-one (trade name "Irugakuyua 651", manufactured by Ciba Corporation of Japan) and 0.05 parts by weight of 1-hydroxycyclohexyl-phenyl ketone (trade name "Irugakuyua 184", (manufactured by Ciba Co., Ltd. Japan) was charged into a four-necked flask, and subjected to partial photopolymerization by exposure to ultraviolet rays under a nitrogen atmosphere, thereby obtaining a partial polymer (monomer slurry) with a polymerization rate of 10%.

[0105] After adding 0.01 weight part of trimethylolpropane triacrylate to 100 weight part of this partial polymer, this was mixed uniformly, and the photopolymerizable composition was prepared.

[0106] (production of adhesive sheet)

[0107] On the release...

Embodiment 3

[0109] (Preparation of photopolymerizable composition)

[0110] 68 parts by weight of 2-ethylhexyl acrylate, 24 parts by weight of 2-methoxyethyl acrylate, 6 parts by weight of N-vinylpyrrolidone, 2 parts by weight of hydroxyethylacrylamide, 0.05 parts by weight of 2,2 - Dimethoxy-1,2-diphenyl-1-ketone (trade name "Irugakuyua 651", manufactured by Ciba Corporation of Japan) and 0.05 parts by weight of 1-hydroxycyclohexyl-phenylketone (tradename "Irugakuyua 184" ", manufactured by Ciba Corporation of Japan) was added in a four-necked flask, and carried out partial photopolymerization by being exposed to ultraviolet rays under a nitrogen atmosphere, thereby obtaining a partial polymer (monomer slurry) with a polymerization rate of 10%.

[0111] After adding 0.015 weight part of trimethylolpropane triacrylates to 100 weight part of polymers of this part, this was mixed uniformly, and the photopolymerizable composition was prepared.

[0112] (production of adhesive sheet)

[0113]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com