Aluminum magnesium continuous casting tundish slag-retaining wall and preparation method thereof

A continuous casting, aluminum-magnesium technology, applied in the field of refractory materials, can solve the problems of low cost performance and high manufacturing cost, etc., and achieve the effects of good resistance to molten steel erosion, long service life, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

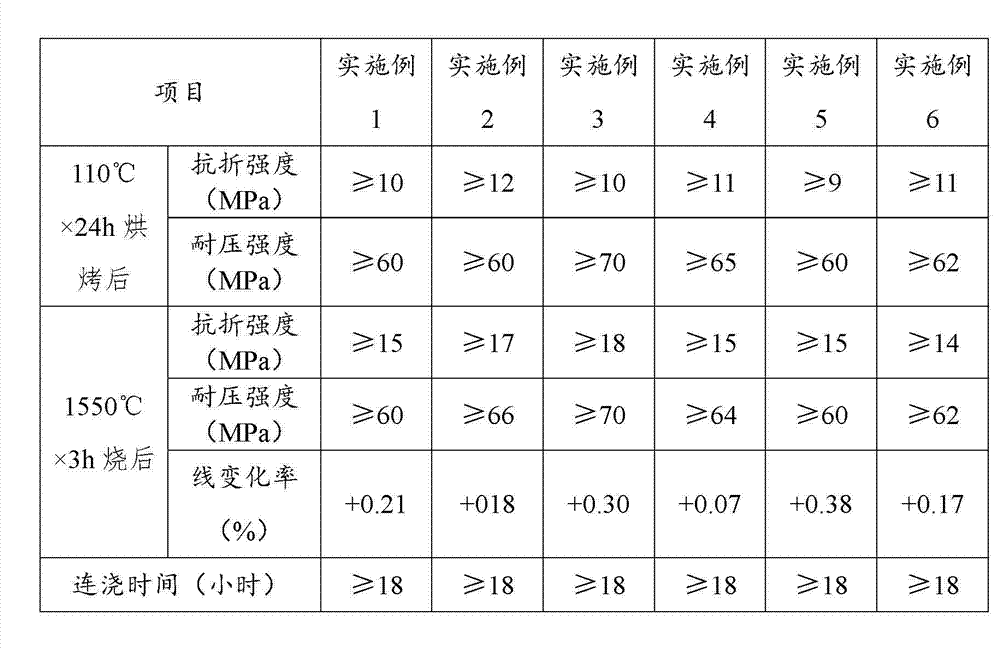

Examples

Embodiment 1

[0029] In this example, the parts by weight of the components of the slag retaining wall of the aluminum-magnesium continuous casting tundish are as follows: high alumina aggregate: 50, magnesium aggregate: 20, fine powder: 20, fine powder: 5, binder : 5, explosion-proof agent: 0.1, water reducing agent: 0.1. Among them, high alumina aggregates include: 8mm2 o 3 The first-grade bauxite with a content of ≥79% accounts for 28%, 17%, 20%, 20% and 15% by weight of the high-alumina aggregate. Magnesia aggregates include: 3mm2 micronized, the SiO 2 Micropowder, SiO 2 Content ≥ 92%, particle size ≤ 45μm. The binder is calcium aluminate cement, and in the calcium aluminate cement, Al 2 o 3 Content ≥ 69%, CaO content ≤ 30%. The explosion-proof agent is polypropylene fiber. The water reducer is a mixture of sodium tripolyphosphate and sodium hexametaphosphate.

Embodiment 2

[0031] In this example, the parts by weight of the components of the slag retaining wall of the aluminum-magnesium continuous casting tundish are as follows: high-alumina aggregate: 70, magnesium aggregate: 5, fine powder: 20, fine powder: 2, binder : 3, explosion-proof agent: 1, water reducing agent: 0.5. Among them, high alumina aggregates include: 8mm2 o 3The super-grade bauxite with a content ≥ 85% accounts for 30%, 15%, 18%, 22% and 15% by weight of the high-alumina aggregate. Magnesia aggregates include: sintered magnesia with MgO content ≥85% in three grades of 5mm2 Micropowder and α-Al 2 o 3 A mixture of micropowders, the SiO 2 Micropowder, SiO 2 Content ≥ 92%, particle size ≤ 45μm, the α-Al 2 o 3 In micropowder, α-Al 2 o 3 Content ≥ 99%, particle size ≤ 2μm. The binder is calcium aluminate cement, and in the calcium aluminate cement, Al 2 o 3 Content ≥ 69%, CaO content ≤ 30%. The explosion-proof agent is glass fiber. The water reducer is sodium tripolypho...

Embodiment 3

[0033] In this example, the parts by weight of the components of the slag retaining wall of the aluminum-magnesium continuous casting tundish are as follows: high alumina aggregate: 60, magnesium aggregate: 8, fine powder: 22, fine powder: 3, binder : 7. Anti-explosion agent: 3. Water reducing agent: 2. Among them, high alumina aggregates include: 8mm2 o 3 The super-grade bauxite with a content ≥ 85% accounts for 32%, 13%, 20%, 22% and 13% by weight of the high-alumina aggregate. Magnesia aggregates include: 8mm2 Micropowder and α-Al 2 o 3 A mixture of micropowders, the SiO 2 Micropowder, SiO 2 Content ≥ 92%, particle size ≤ 45μm, the α-Al 2 o 3 In micropowder, α-Al 2 o 3 Content ≥ 99%, particle size ≤ 2μm. The binder is calcium aluminate cement, and in the calcium aluminate cement, Al 2 o 3 Content ≥ 69%, CaO content ≤ 30%. The explosion-proof agent is stainless steel fiber. The water reducer is dispersed alumina (brand: ADS1 / ADW1, produced by Qingdao Anmai Alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com