A kind of self-curing tundish dry material and preparation method thereof

A self-curing and auxiliary material technology, applied in the field of refractory materials, can solve the problems of not meeting the requirements of clean steel production, long baking time, and reducing the quality of steel billets, so as to solve the pollution problem and the hidden safety hazards and corrosion resistance of gas baking. Excellent, convenient and quick construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

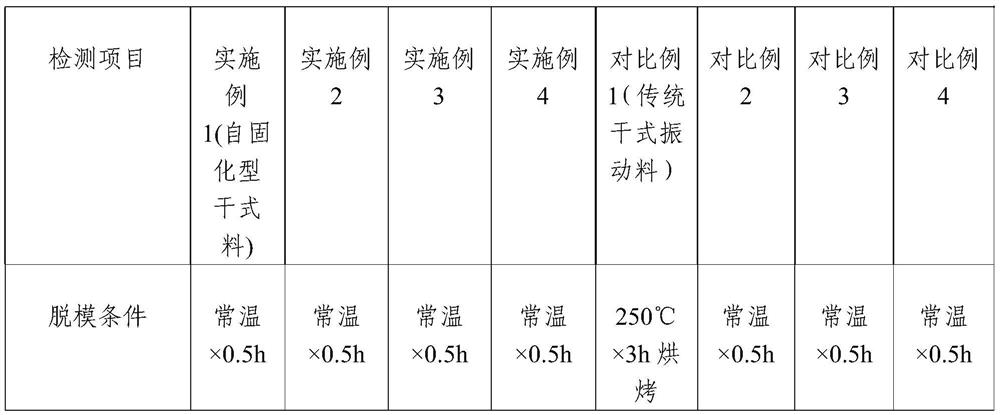

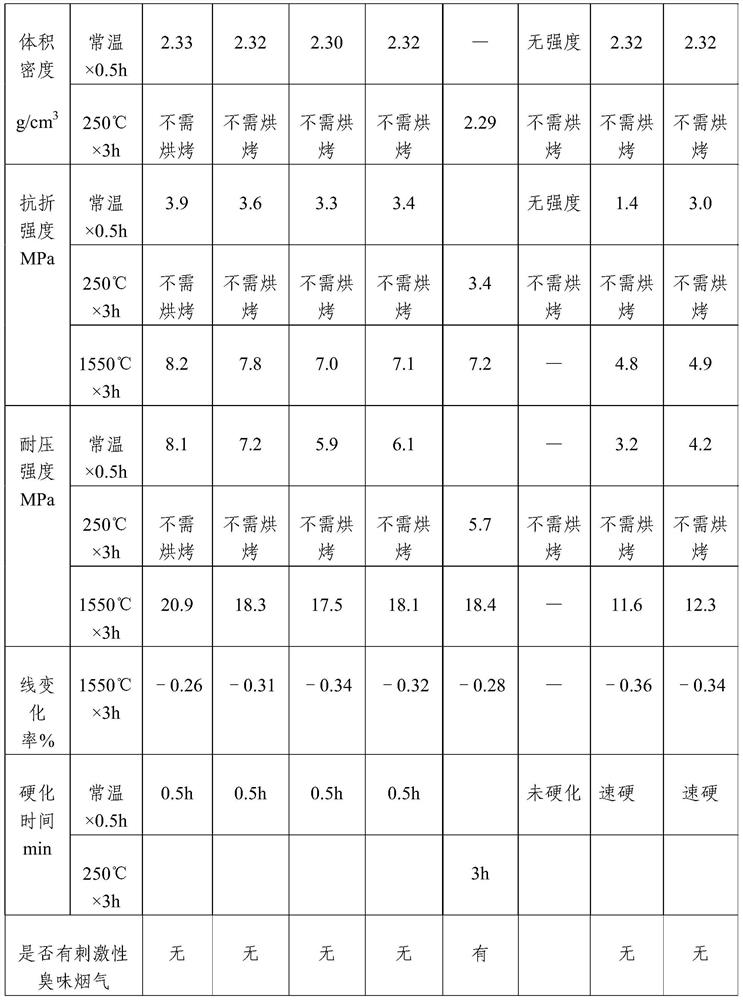

Examples

Embodiment 1

[0038] The present invention relates to a kind of tundish dry-type material, which is prepared from the following components:

[0039] 90 parts of magnesia, 10 parts of forsterite, 10 parts of magnesia brick crushing material, 3 parts of Guangxi white mud, 0.15 parts of explosion-proof agent aluminum lactate, 5 parts of compound binder;

[0040] The composite binding agent includes 2 parts of maleic acid, 2 parts of citric acid, and 1 part of calcium chloride.

[0041] The tundish dry feed of the present invention is prepared by the following method:

[0042] 1) Stir the above components according to the proportions for 5-10 minutes until the mixture is uniform to obtain a dry, loose and uniform self-curing tundish dry bulk material, which is bagged and sealed.

[0043] 2) Pour the bulk material into the mixer to add water and stir, and the mixed dry material is transported to the tundish and vibrated to make it evenly filled and covered with the working layer, and placed on ...

Embodiment 2

[0045] The present invention relates to a kind of tundish dry feed, which is prepared from the following components:

[0046] 60 parts of magnesia, 10 parts of forsterite, 30 parts of magnesia brick crushing material, 5 parts of Guangxi white mud, 0.15 parts of explosion-proof agent aluminum lactate, 4.8 parts of compound binder;

[0047] The composite binder includes 2 parts of tartaric acid, 2 parts of oxalic acid, and 0.8 part of magnesium sulfate.

Embodiment 3

[0049] The present invention relates to a kind of tundish dry-type material, which is prepared from the following components:

[0050] 58 parts of magnesia, 35 parts of forsterite, 10 parts of magnesia brick crushing material, 3 parts of Guangxi white mud, 2 parts of composite binder, 0.15 parts of explosion-proof agent and explosion-proof fiber;

[0051] The composite binder includes 0.5 part of oxalic acid, 0.5 part of p-toluenesulfonic acid, and 1 part of aluminum chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com