Flint clay brick with acid and alkali resistance, wear resistance and thermal shock resistance as well as preparation method thereof

A manufacturing method and technology for resisting thermal shock, applied in the field of refractory materials, can solve the problems of high acid-base atmosphere, high ash concentration and high flow rate, and achieve the effects of good thermal shock resistance, simple manufacturing process and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

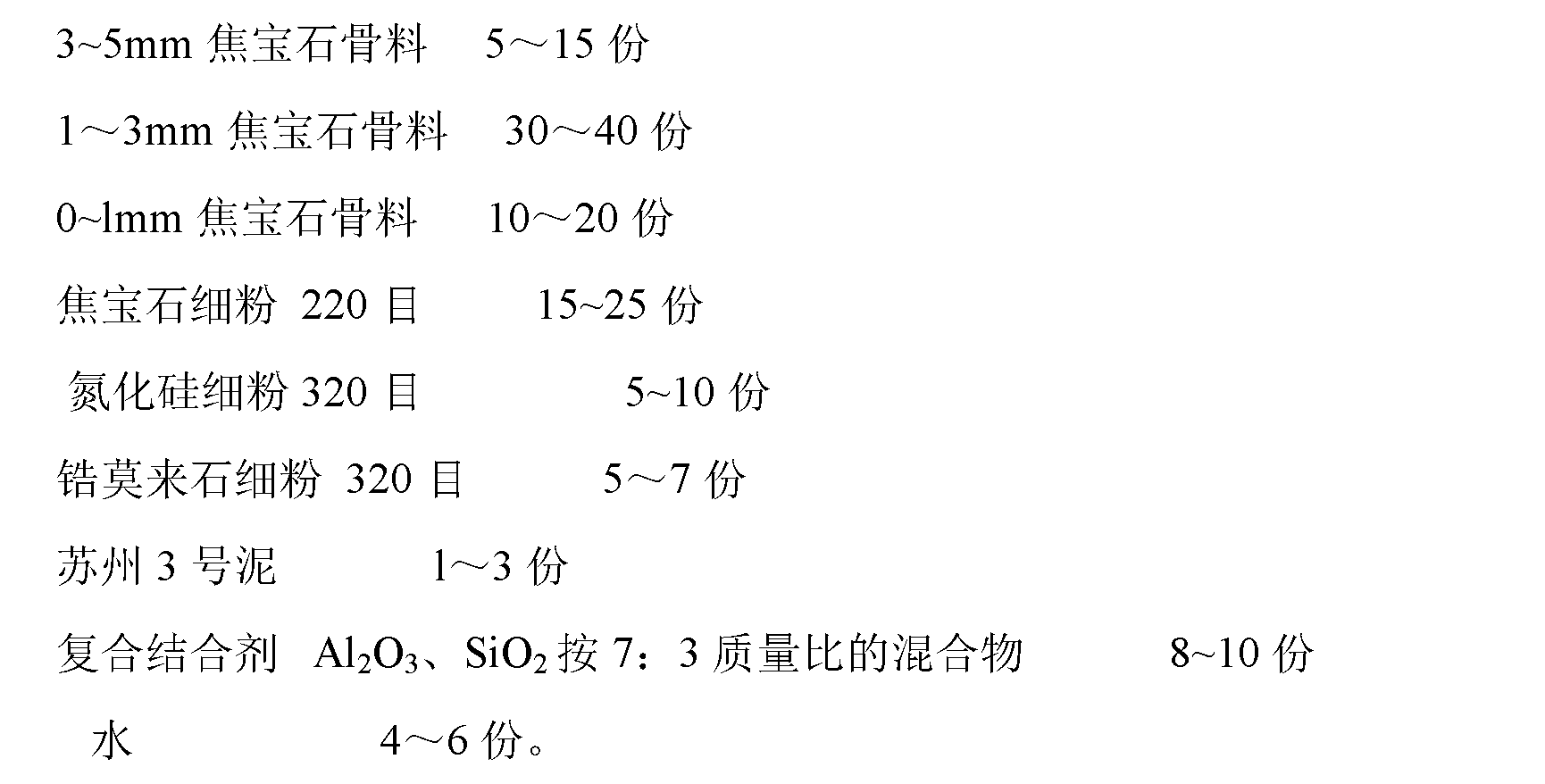

[0028] 15 parts of 3~5mm burnt gem aggregate, 30 parts of 1~3mm burnt gem aggregate, 20 parts of 0~1mm burnt gem aggregate, 23 parts of 220 mesh burnt gem fine powder, 5 parts of silicon nitride fine powder powder, 5 parts of 320-mesh zircon mullite fine powder, 2 parts of Suzhou No. 3 mud, 9 parts of composite binder, and 4 parts of water are mixed and pressed on a 1,000-ton friction brick press. The bulk density of the semi-finished product is 2.10~2.30g. cm -3 . After baking at 90°C for 24 hours, the residual moisture of the green body is ≤2%. Firing can be fired in pusher kiln or tunnel kiln, and fired at 1350°C for 4 hours to get the desired finished acid and alkali resistant, wear resistant, thermal shock and coke bricks.

Embodiment 2

[0030] Take 10 parts of 3~5mm coke gemstone aggregate, 36 parts of 1~3mm coke gemstone aggregate, 15 parts of 0~1mm coke gemstone aggregate, 26 parts of 220 mesh coke gemstone fine powder, 6 parts of silicon nitride fine powder , 6 parts of 320-mesh zircon mullite fine powder, 1 part of Suzhou No. 3 mud, 8 parts of composite binder, 5 parts of water are mixed and pressed on a 1000-ton friction brick press, and the bulk density of semi-finished products is 2.1~2.3g.cm -3 . After baking at 80°C for 36 hours, the residual moisture of the green body is ≤2%. Firing can be fired in pusher kiln or tunnel kiln, and fired at 1350°C for 3 hours to obtain the desired finished acid and alkali resistant, wear-resistant, heat-shock, and coke-resistant gemstone bricks.

Embodiment 3

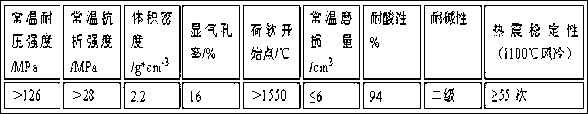

[0032] The physical properties of the acid and alkali-resistant, wear-resistant, heat-shock, and coke bricks of the present invention are tested, and the results are as follows:

[0033] Table 1 The physical properties of the acid and alkali-resistant wear-resistant thermal shock-resistant coke gem brick brick of the present invention

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com