A kind of pelletizing rotary kiln anti-spalling refractory castable and preparation method thereof

A technology of refractory castables and rotary kilns, which is applied in the field of refractory materials for lining of high-temperature furnaces and kilns. It can solve the problems of affecting the service life of rotary kiln linings, the operating conditions of rotary kilns, the increase of production costs, and frequent maintenance, so as to reduce the number of maintenance. and pellet production cost, extended service life, and improved spalling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

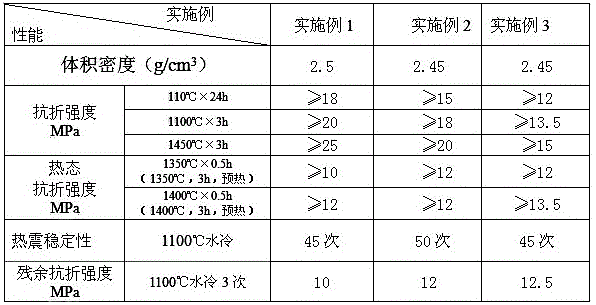

Examples

Embodiment 1

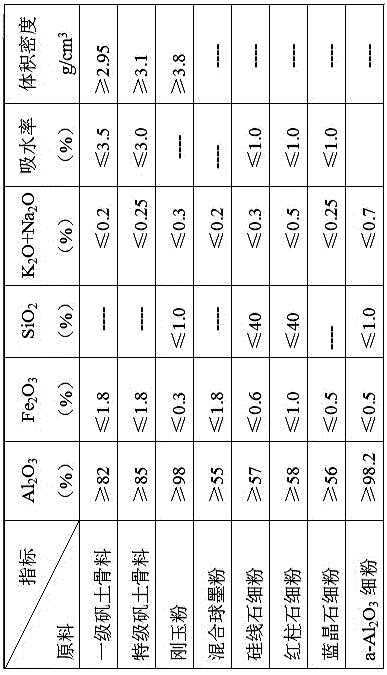

[0016] Example 1: A pelletized rotary kiln anti-stripping refractory castable, the weight percentage of each raw material is as follows: first-grade bauxite aggregate: 40%, super-grade bauxite aggregate: 20%, mixed nodular powder: 8%, silicon Fine powder of lineite: 15%, fine powder of kyanite: 5%, a-Al 2 o 3 Fine powder: 5%, zirconium boride powder: 0.1%, binder: 6.85%, admixture: 0.05%.

[0017] A kind of preparation method of anti-stripping refractory castable for pelletizing rotary kiln as above, its preparation method is as follows: first mix spheroidal powder, sillimanite fine powder and kyanite fine powder for 3 minutes, prepare mixed fine powder ; Then mix the first-grade bauxite aggregate and super-grade bauxite aggregate with 5-3, 3-1, 1-0.5 third-grade ingredients for 3 minutes to prepare mixed aggregate; then add the prepared mixed fine powder In the prepared mixed aggregate, add the mixed fine powder while stirring, and stir for another 2 minutes after adding; ...

Embodiment 2

[0018] Example 2: A pelletized rotary kiln anti-stripping refractory castable, the weight percentage of each raw material is as follows: first-grade bauxite aggregate: 30%, super-grade bauxite aggregate: 25%, corundum powder: 4%, mixed nodular graphite Powder: 9.8%, sillimanite fine powder: 10%, andalusite fine powder: 5%, kyanite fine powder: 5%, a-Al 2 o 3 Fine powder: 3%, zirconium boride powder: 2%, binder: 2%, admixture: 0.2%.

[0019] A kind of preparation method of anti-stripping refractory castable for pelletizing rotary kiln as above, its preparation method is as follows: firstly corundum powder, mixed nodular powder, sillimanite fine powder, andalusite fine powder and kyanite fine powder are mixed 5 minutes to prepare mixed fine powder; then mix the first-grade bauxite aggregate and super-grade bauxite aggregate with 10-5, 5-3, 3-0.5 third-grade ingredients for 2 minutes to prepare mixed aggregate; then Add the prepared mixed fine powder into the prepared mixed ag...

Embodiment 3

[0020] Example 3: A pelletized rotary kiln anti-stripping refractory castable, the weight percentage of each raw material is as follows: first-grade bauxite aggregate: 35%, super-grade bauxite aggregate: 22%, corundum powder: 7.4%, mixed nodular graphite Powder: 15%, sillimanite fine powder: 5%, andalusite fine powder: 3%, a-Al 2 o 3 Fine powder: 4%, zirconium boride powder: 1.5%, binder: 7%, admixture: 0.1%.

[0021] A kind of preparation method of anti-stripping refractory castable for pelletizing rotary kiln as described above, its preparation method is as follows: firstly corundum powder, mixed nodular powder, sillimanite fine powder and andalusite fine powder are mixed for 4 minutes to prepare a mixed fine powder; then the first-grade bauxite aggregate and super-grade bauxite aggregate are mixed with 10-5, 5-3, 3-0.5 third-grade ingredients for 1 minute to prepare mixed aggregate; then the prepared mixed fine powder Add the powder into the prepared mixed aggregate, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com