Polyester fiber dyeing carrier and preparation method thereof

A technology of carrier and polyester, which is applied in the field of environmentally friendly polyester dyeing carrier and its preparation, can solve the problems of high price of N-alkylpyrrolidone, difficulty in popularization and acceptance, and residual cloth surface, etc., and achieve lower dyeing temperature and dyeing equipment requirements Low, high color yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

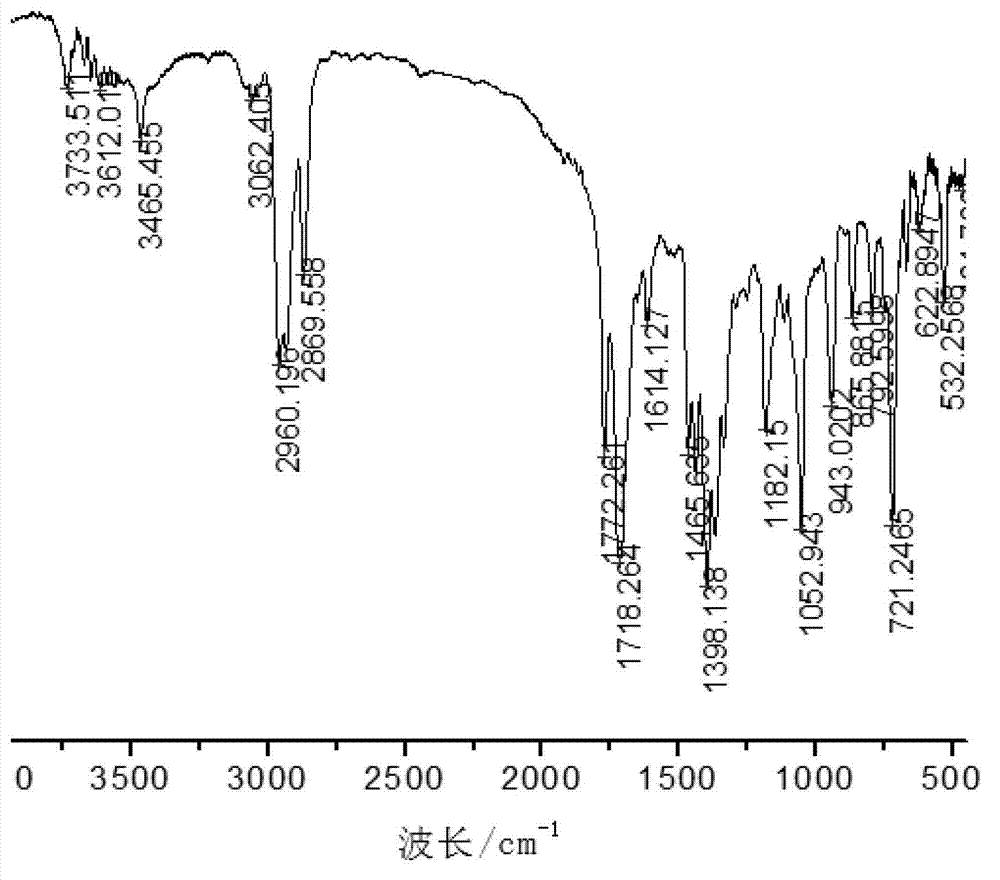

[0037] Such as figure 1 Shown, a kind of polyester dyeing carrier comprises the component of following structural formula:

[0038]

[0039]

[0040] where R 1 , R 2 , R 3 , R 4 , R 5 , R 6 , R 7 is straight chain or branched chain alkyl;

[0041] Wherein the structure (4) is the main component of the carrier.

[0042] The present invention also provides a method for preparing the above-mentioned polyester dyeing carrier: comprising the following specific steps:

[0043] (1) Synthesis of carrier

[0044] Vacuum pump 300Kg of environmentally friendly solvent into the reaction kettle, then add 3.3756kmol fatty acid anhydride or aromatic acid anhydride, 1.6074kmol alkylamine or alkyldiamine, heat to 50°C, carry out ring-opening addition reaction, and keep warm for 1h;

[0045]Then, the temperature in the kettle was raised to 180° C., and the temperature was kept at reflux for 10 hours to carry out the dehydration ring-closing reaction.

[0046] Sampling is ta...

Embodiment 2

[0064] All the other are identical with above-mentioned embodiment, difference is, the present invention also provides the method for preparing above-mentioned polyester dyeing carrier: comprise following specific steps:

[0065] (1) Synthesis of carrier

[0066] Vacuum pump 300Kg of environmentally friendly solvent into the reaction kettle, then add 3.3756kmol fatty acid anhydride or aromatic acid anhydride, 1.6074kmol alkylamine or alkyldiamine, heat to 60°C, carry out ring-opening addition reaction, and keep warm for 2 hours;

[0067] Then, the temperature in the kettle was raised to 200° C., and the temperature was kept at reflux for 14 hours to carry out the dehydration ring-closing reaction.

[0068] (2) Carrier emulsification

[0069] The emulsifier is added to the carrier component at a mass ratio of 1:1, wherein the mass ratio of fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether phosphate and styrylphenol polyoxyethylene ether sulfonate is 1: ...

Embodiment 3

[0073] All the other are identical with above-mentioned embodiment, difference is, the present invention also provides the method for preparing above-mentioned polyester dyeing carrier: comprise following specific steps:

[0074] (1) Synthesis of carrier

[0075] Vacuum pump 300Kg of environmentally friendly solvent into the reaction kettle, then add 3.3756kmol fatty acid anhydride or aromatic acid anhydride, 1.6074kmol alkylamine or alkyldiamine, heat to 70°C, carry out ring-opening addition reaction, and keep warm for 3 hours;

[0076] Then, the temperature in the kettle was raised to 220° C., and the temperature was kept at reflux for 18 hours to carry out the dehydration ring-closing reaction.

[0077] (2) Carrier emulsification

[0078] The emulsifier is added to the carrier component at a mass ratio of 4:1, wherein the mass ratio of fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether phosphate and styrylphenol polyoxyethylene ether sulfonate is 2: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com