High-water-level silty-soil underneath-pass multi-track railway frame bridge jacking and butting construction method

A construction method and technology of silt soil, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as affecting construction efficiency and construction period, difficult to ensure the safety of line traffic, large impact on railway traffic, etc., to reduce operation. and operational safety, reducing the effect of beam reinforcement lines, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and non-limiting embodiment:

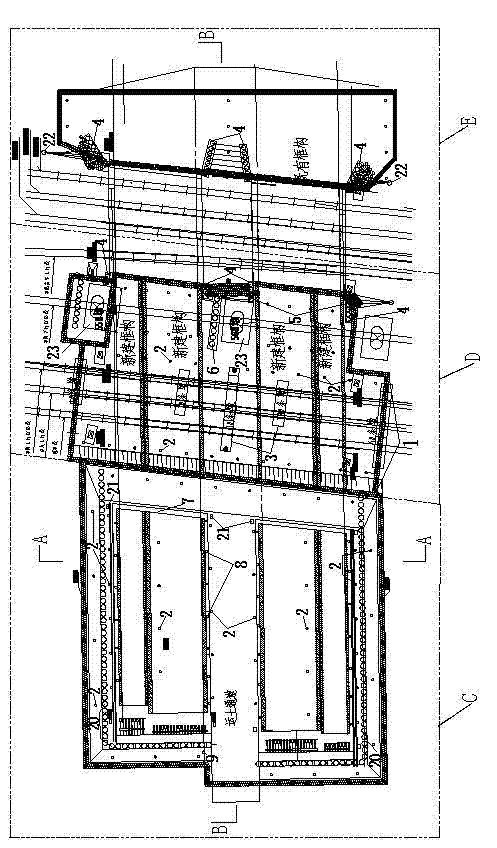

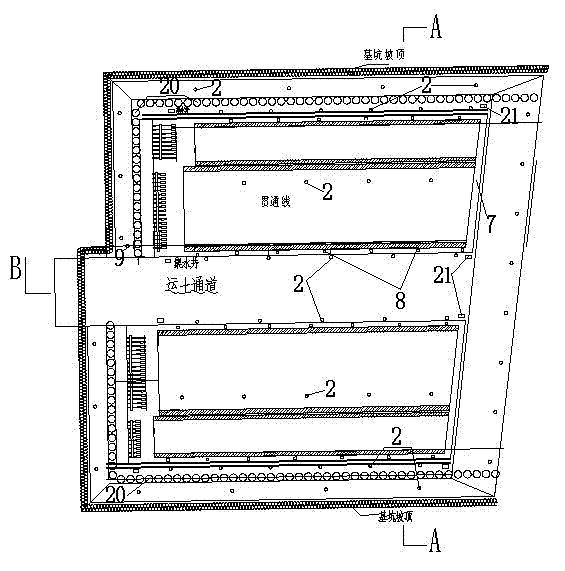

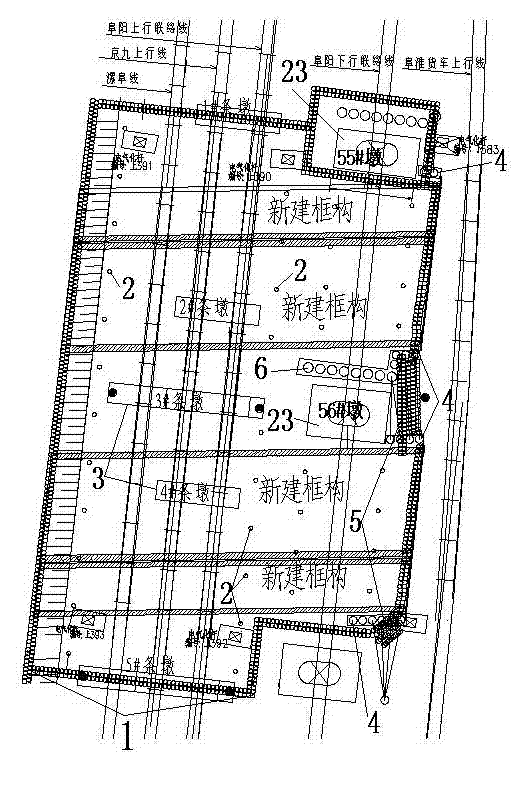

[0028] The invention is aimed at the jacking and butt jointing construction method of the multi-strand railway frame under the silt soil with high water level. As shown in the attached figure, the new frame is docked with the existing frame, and the new frame structure passes through Luofu Line, Beijing-Kowloon Uplink Line, and Fuyang Uplink Line, a total of 3 existing railway lines, with line spacing of 5.35m and 5.21m respectively. The intersection angles are 82.9°, 83.2°, and 83.2°, respectively. The frame structure adopts a 5.4m+12m+12m+5.4m four-hole separated jacking frame, the frame structure is obliquely made, and the intersection angle is 82.46° on the left line (83.02° on the right line). The newly-built frame is directly connected to the existing frame, the design width of the side hole frame structure section is 5.4m; the frame struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com