Efficient-radiation LED lamp and production method thereof

A technology of LED lamps and LED lamps, which is applied in the direction of lighting and heating equipment, lampshades, components of lighting devices, etc. It can solve the problems of accelerating the speed of LED light decay, unsatisfactory heat dissipation, and shortening service life, etc., and achieves a simple structure , Solve the heat dissipation problem and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

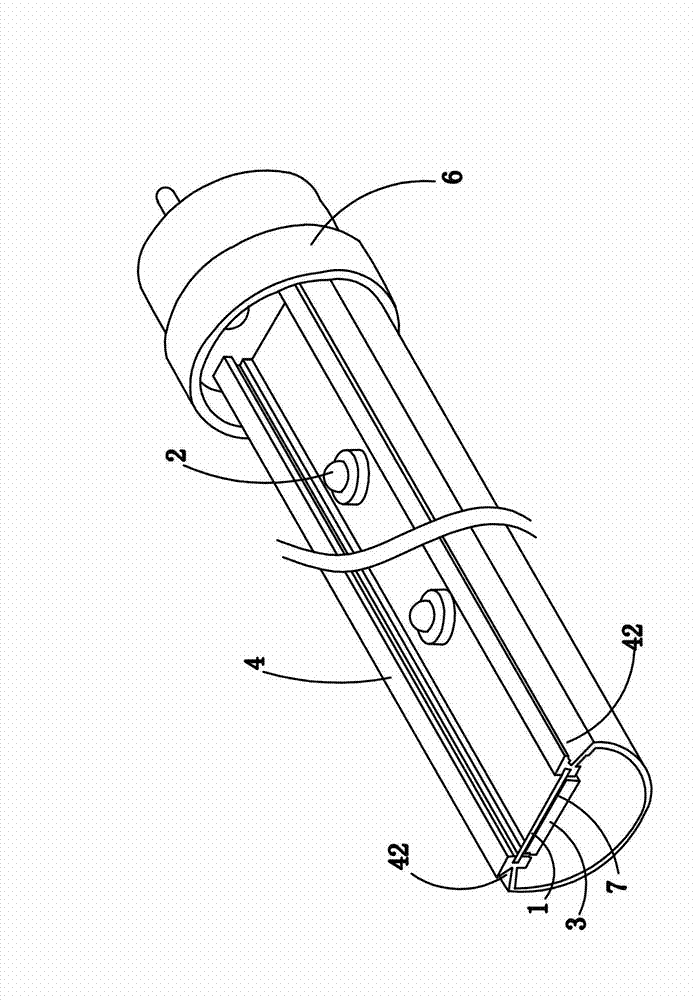

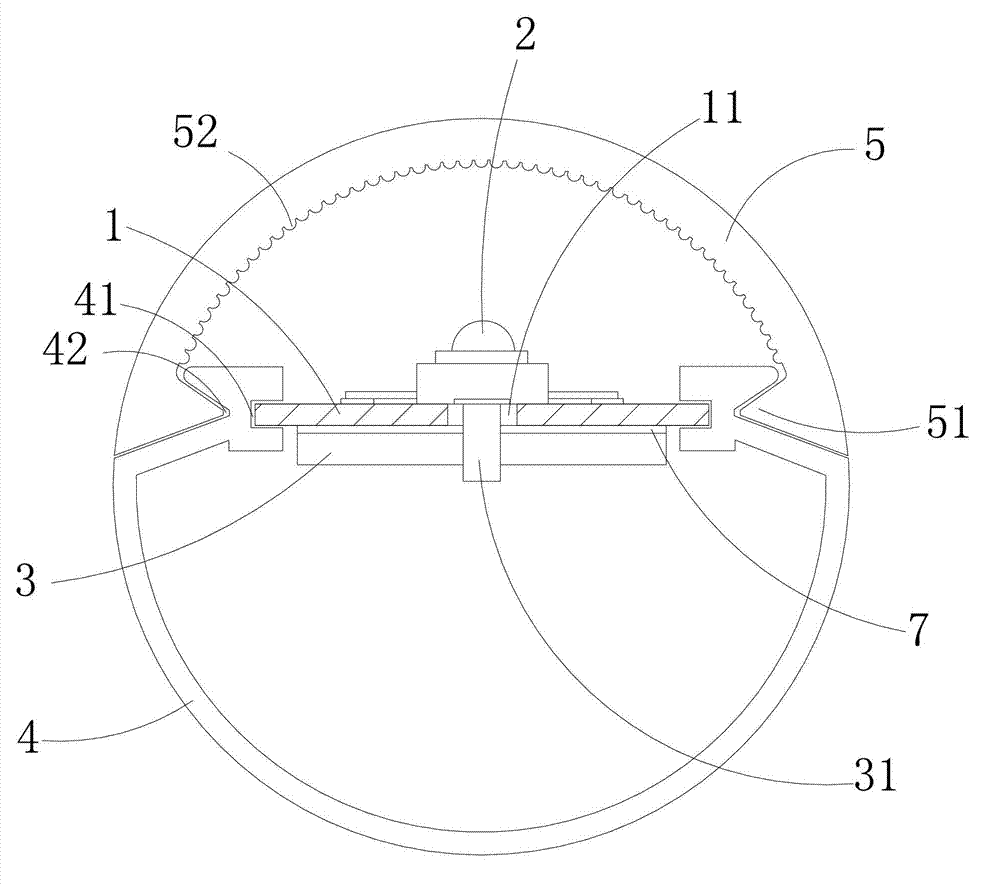

[0022] Example: see figure 1 and figure 2 , a method for preparing a high-efficiency heat dissipation LED lamp of the present invention, which comprises the following steps:

[0023] (1) Prepare a strip-shaped PCB welding board 1, set a printed circuit connected to the LED lamp 2 on the PCB welding board 1, and evenly weld several LED lamps 2 on the PCB welding board 1, directly below the LED lamp 2 The PCB welding board 1 is provided with a through hole 11;

[0024] (2) A strip-shaped graphite radiator 3 is prepared by using graphite, and a number of thermally conductive rivets 31 are evenly arranged on the graphite radiator 3 , the heads of the thermally conductive rivets 31 protrude from the graphite radiator 3 , and two adjacent thermally conductive rivets 31 The spacing between them is equal to the spacing between two adjacent LED2 lamps on the PCB welding board 1;

[0025] (3) Coating thermal paste on the upper surface of the graphite radiator 3 and the top of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com