Sterilization and drying method for pine pollen

A drying method, pine pollen technology, applied in application, food preparation, food science, etc., can solve the problems of nutrient loss, pine pollen structure damage, etc., and achieve the effects of improving production efficiency, facilitating long-term preservation, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

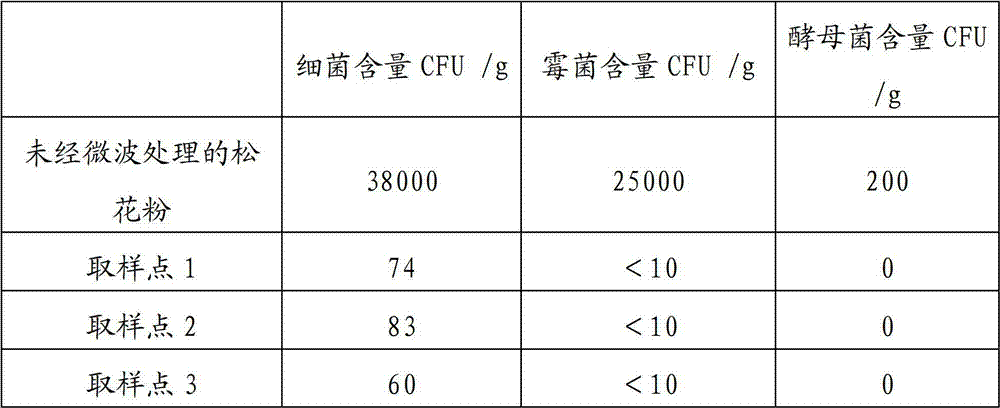

Embodiment 1

[0024] Weigh an appropriate amount of pine pollen and add it to the fluidized bed spraying equipment, spray the pine pollen with 80°C steam, when the temperature of the pine pollen reaches 60°C and the moisture content reaches 50%, take out the pine pollen; the sprayed pine pollen Evenly distribute the material on the conveyor belt of the tunnel-type microwave sterilization equipment, turn on the microwave, the power is 30kw, the sterilization time is 5 minutes, and the temperature is controlled at 70°C; after the sterilization operation, quickly transfer the pine pollen to the drying process, turn on the microwave 12kw, and dry The time is 6 minutes, the temperature is controlled at 40°C, and the moisture content of the pine pollen is detected to be 8%. After the drying operation, the pine pollen is collected in a plastic bag and stored in a sealed room at room temperature for future use.

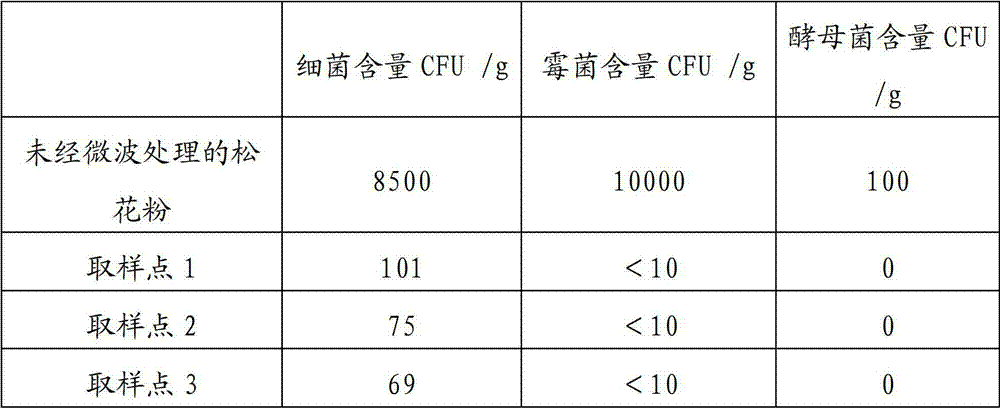

example 2

[0026] Weigh an appropriate amount of pine pollen and add it to the fluidized bed spraying equipment, spray the pine pollen with steam at 100°C, and when the temperature of the pine pollen reaches 60°C and the moisture content reaches 60%, take out the pine pollen; the sprayed pine pollen Evenly distribute the material on the conveyor belt of the tunnel-type microwave sterilization equipment, turn on the microwave, the power is 35kw, the sterilization time is 3 minutes, and the temperature is controlled at 60°C; after the sterilization operation, quickly transfer the pine pollen to the drying process, turn on the microwave 10kw, and dry The time is 4 minutes, the temperature is controlled at 50°C, and the moisture content of the pine pollen is detected to be 10%. After the drying operation, the pine pollen is collected in a plastic bag and stored in a sealed room at room temperature for future use.

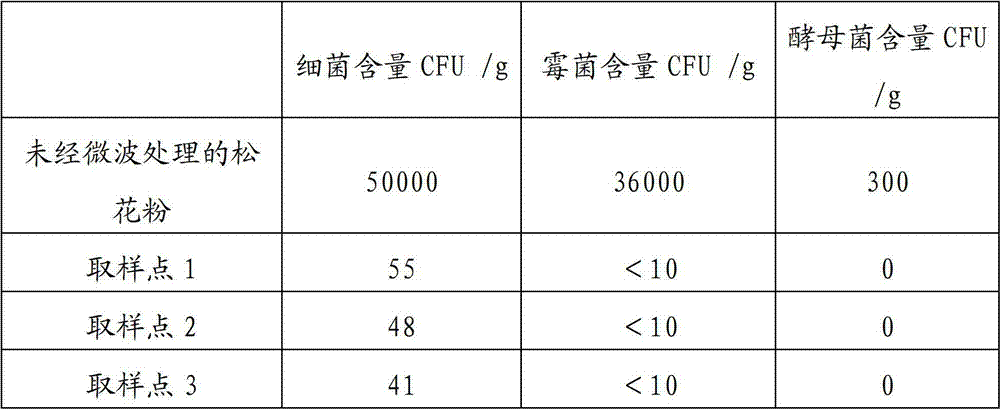

example 3

[0028] Weigh an appropriate amount of pine pollen and add it to the fluidized bed spraying equipment, spray the pine pollen with 110°C steam, when the temperature of the pine pollen reaches 70°C and the moisture content reaches 60%, take out the pine pollen; the sprayed pine pollen Evenly distribute the material on the conveyor belt of the tunnel-type microwave sterilization equipment, turn on the microwave, the power is 40kw, the sterilization time is 8 minutes, and the temperature is controlled at 95°C; after the sterilization operation, quickly transfer the pine pollen to the drying process, turn on the microwave 15kw, and dry The time is 7 minutes, the temperature is controlled at 60°C, and the moisture content of the pine pollen is detected to be 3%. After the drying operation, the pine pollen is collected in a plastic bag and stored in a sealed room at room temperature for future use.

[0029] Following table 1 is each microbial detection index of the pine pollen prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com