Medical degradable magnesium alloy bone-fixing screw

A technology of fixation screw and magnesium alloy, which is applied in the field of bone fixation screws, can solve the problems that bone fixation screws cannot be degraded, and achieve the effects of avoiding stress shielding effect, less tissue reaction, and reducing trauma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

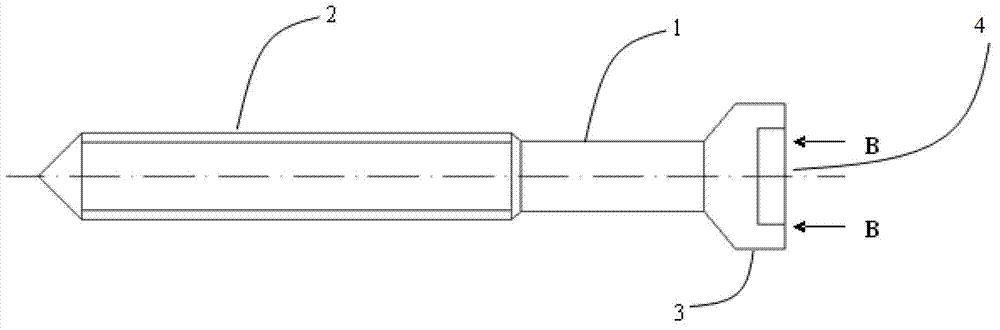

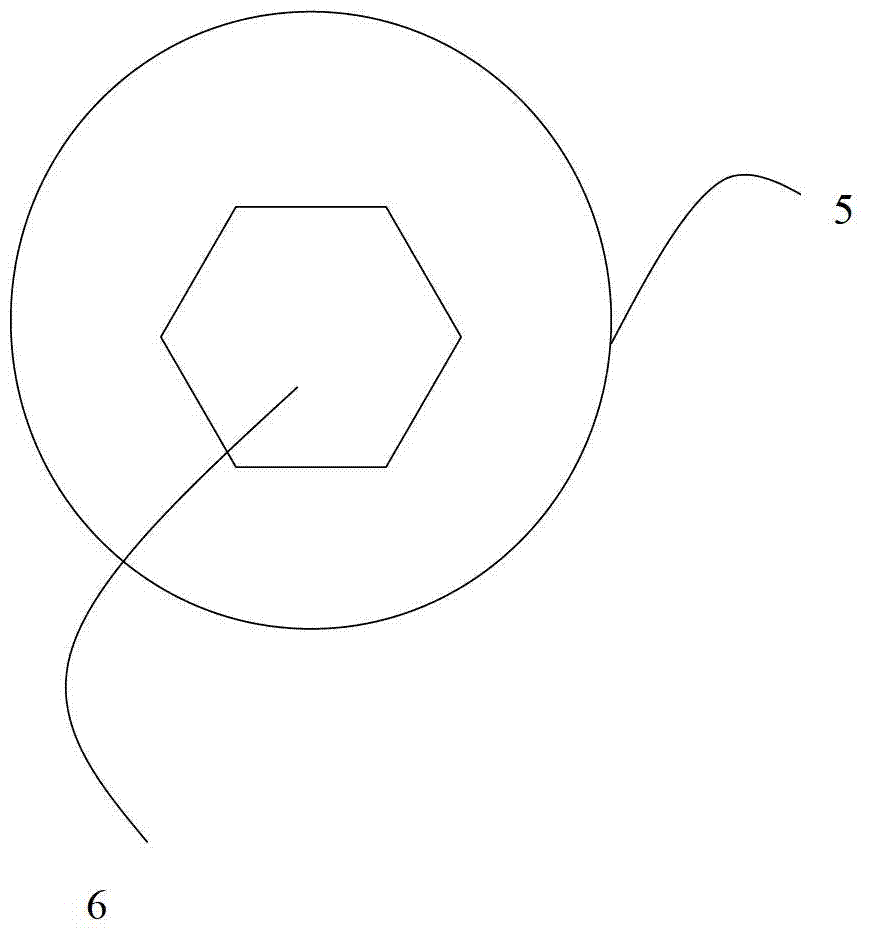

[0021] Embodiment 1: In this embodiment, the degradable magnesium alloy bone fixation screw includes a degradable magnesium alloy.

[0022] The beneficial effect of this embodiment is:

[0023] 1) Magnesium is one of the most abundant metal elements on the earth and one of the most abundant cations in the human body. It is an indispensable and important nutritional element for the human body. As a new type of biomedical material, magnesium alloy has good medical properties. It is a safe foundation and has the following medical advantages: 1) The elastic modulus and yield strength of Mg are closer to those of human bone, and the density is also very similar to that of human bone, which can effectively avoid the stress shielding effect; 2) Magnesium Alloys are basic elements in human metabolism and bone tissue, and have better biocompatibility; 3) Magnesium has a very low equilibrium electrode potential, especially in a solution containing Cl, which is easily corroded and degrad...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the degradable magnesium alloy is composed of Mg-Ca alloy, Mg-Sn-Mn alloy or Mg-Sn-Mn-Zn alloy. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 to Embodiment 2 in that the weight percentage of Ca in the Mg-Ca alloy is 1%-30%. Others are the same as one of the specific embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com