Fire-proofing and heat-insulating composite fabric with second order phase transition temperature limit, and preparation method and application thereof

A composite fabric, temperature-limiting technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of short pause time, burns or burns, and weak flame impact resistance of thermal protective fabrics or clothing, reaching Easy to adjust the structure and the effect of forming processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

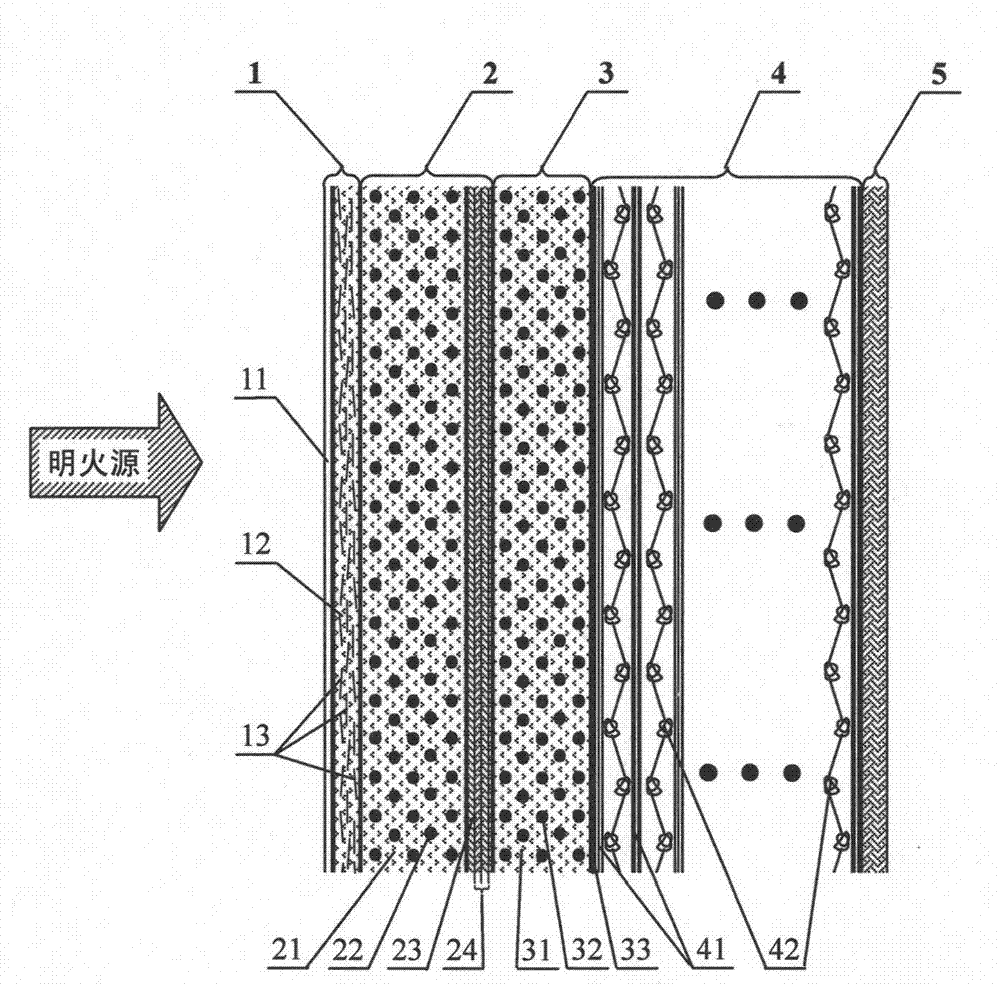

[0058] The present invention also provides a method for preparing the above-mentioned two-stage phase change step temperature-limited fire-proof and heat-insulating composite fabric, which is characterized in that the steps are: firstly, the above-mentioned metal foil 11 except the metal foil felt heat-reflecting composite layer 1 The finished layers or compound layers are stitched and fixed to form a composite fabric, and then the metal foil 11 is uniformly and point-bonded on the outermost surface with a high-temperature-resistant adhesive to form a natural thickness of 5-15mm, and the actual compression The thickness is 3-8mm, and the square meter mass is 400-1500g / m 2 A two-stage phase change ladder temperature-limited fire-resistant and thermally insulating composite fabric.

[0059] More preferably, the natural thickness of the sum of the first phase-change temperature-limiting layer 2, the second phase-change temperature-limiting layer 3 and the spacer composite film in...

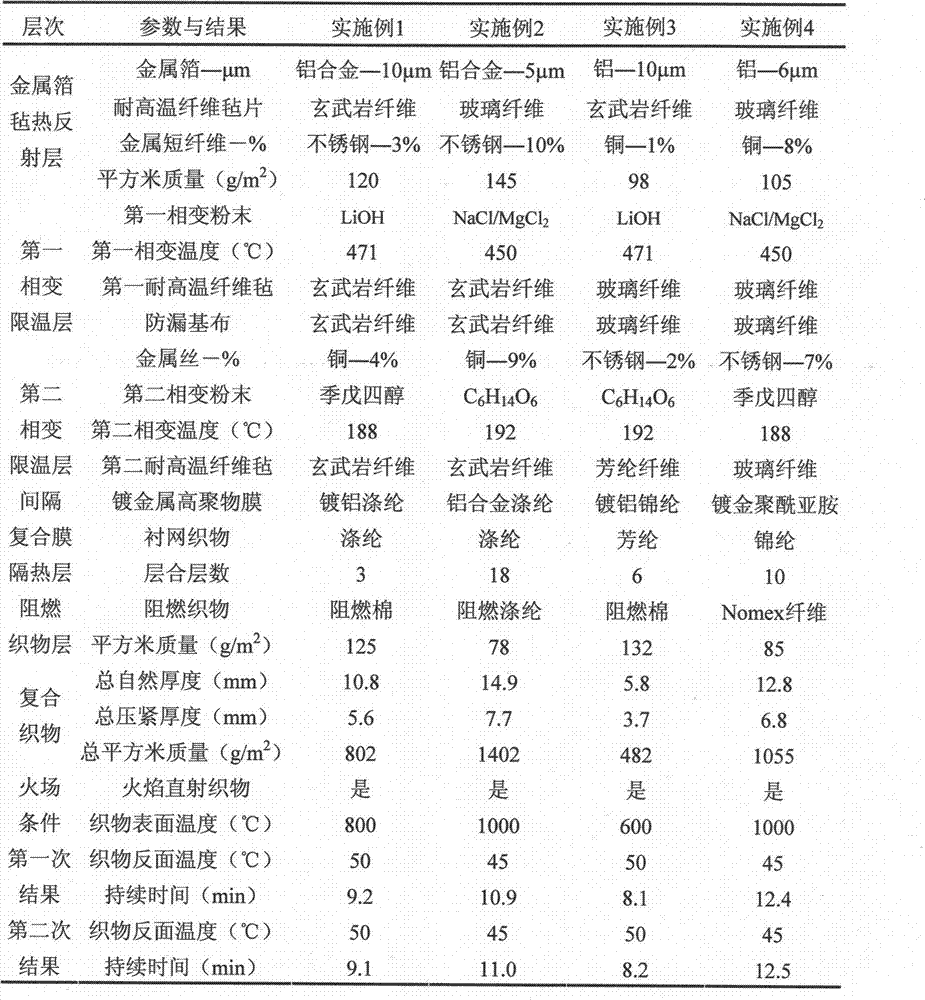

Embodiment 1

[0062] Using the five-layer structure of the fire-proof and heat-insulating composite fabric with two-stage phase change step temperature limit of the present invention and the materials in the following table, and using the preparation method described in the present invention to prepare the fire-proof and heat-insulating composite fabric, place it at 800 ° C Under the conditions of the fire scene, the maximum temperature and the maximum duration of the measured inner side, namely the reverse side, are shown in the Example 1 column of the table below. Actual visual observation shows that the surface is intact, and there are no obvious embrittlement points or cracks when kneading and bending. After cooling, put it into the same fire field conditions again, the limited maximum temperature and the longest duration time of the second treatment obtained are shown in the table below, indicating that there is no change; Kneading and bending without obvious embrittlement points or cr...

Embodiment 2

[0064] Using the five-layer structure of the fire-proof and heat-insulating composite fabric with two-stage phase change step temperature limit of the present invention and the materials in the following table, and using the preparation method of the present invention to prepare the fire-proof and heat-insulating composite fabric, place it at 1000 ° C Under the conditions of the fire scene, the maximum temperature and the maximum duration of the measured inner side, namely the reverse side, are shown in the column of Example 2 in the following table. Actual visual observation shows that the surface is intact, and there are no obvious embrittlement points or cracks when kneading and bending. After cooling, put it into the same fire site again. The maximum limited temperature and the longest duration of the obtained second treatment are shown in the table below. It shows that there is no change, and the longest duration is slightly increased, which is the material. It is caused ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com