Anti-skinning spray coating material for cement kiln

An anti-skin and paint spray technology, applied in the field of refractory spray paint, can solve the problems of high water addition in pouring construction, cannot be used for a long time, and does not have anti-skin and other problems, and achieves outstanding thermal shock stability performance, low rebound rate, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An anti-skinning spray paint for a cement kiln, in terms of mass percentage, its components consist of:

[0027] Burnt gemstones with a particle size of 3-5mm 21%;

[0028] Burnt gemstones with a particle size of 1-3mm 19%;

[0029] Burnt gemstones with a particle size of 0.088-1mm 14%;

[0030] SiC 7% with a particle size of 0.088-1mm;

[0031] Guangxi white mud 7%;

[0032] α-Al 2 o 3 Micropowder 4%;

[0033] High alumina bauxite fine powder 6%;

[0034] SiC fine powder 6%;

[0035] Pure calcium aluminate cement 11%;

[0036] Spodumene 2%;

[0037] Pyrophyllite 3%;

[0038] The sum of the contents of the above components is 100%.

[0039] The above-mentioned anti-skinning spray paint for cement kiln, in terms of mass ratio, its component composition also includes polypropylene fiber, and the specific content ratio is: the total content of the above-mentioned components: polypropylene fiber is 1:0.0014.

[0040] Al in the burnt gem 2 o 3 The content is 50...

Embodiment 2

[0043] An anti-skinning spray paint for a cement kiln, in terms of mass percentage, its components consist of:

[0044] Burnt gemstones with a particle size of 3-5mm 23%;

[0045] Burnt gemstones with a particle size of 1-3mm 13%;

[0046] Burnt gemstones with a particle size of 0.088-1mm 14%;

[0047]SiC 11% with a particle size of 0.088~1mm;

[0048] Guangxi white mud 7%;

[0049] α-Al 2 o 3 Micropowder 7%;

[0050] High alumina bauxite fine powder 6%;

[0051] SiC fine powder 4%;

[0052] Pure calcium aluminate cement 13%;

[0053] Spodumene 2%;

[0054] Al in the burnt gem 2 o 3 The content of SiC is 51.3%; the SiC content in SiC and SiC fine powder with a particle size of 0.088-1mm is 90.8%; the Al in Guangxi white mud 2 o 3 The content is 32%; α-Al 2 o 3 Al in micropowder 2 o 3 The content is 95%; Al in the fine powder of high alumina bauxite 2 o 3 The content is 72%; Al in pure calcium aluminate cement 2 o 3 The content is 67.8%, and the initial set...

Embodiment 3

[0057] An anti-skinning spray paint for a cement kiln, in terms of mass percentage, its components consist of:

[0058] Burnt gemstones with a particle size of 3-5mm 15%;

[0059] Burnt gemstones with a particle size of 1-3mm 15%;

[0060] Burnt gemstones with a particle size of 0.088-1mm 14%;

[0061] SiC 9% with a particle size of 0.088~1mm;

[0062] Guangxi white clay 6%;

[0063] α-Al 2 o 3 Micropowder 4%;

[0064] High alumina bauxite fine powder 6%;

[0065] SiC fine powder 6%;

[0066] Pure calcium aluminate cement 20%;

[0067] Spodumene 1%;

[0068] Pyrophyllite 4%;

[0069] The index content and using method of each component in this spray paint are the same as embodiment two, and Al in pyrophyllite 2 o 3 The content is 28.9%.

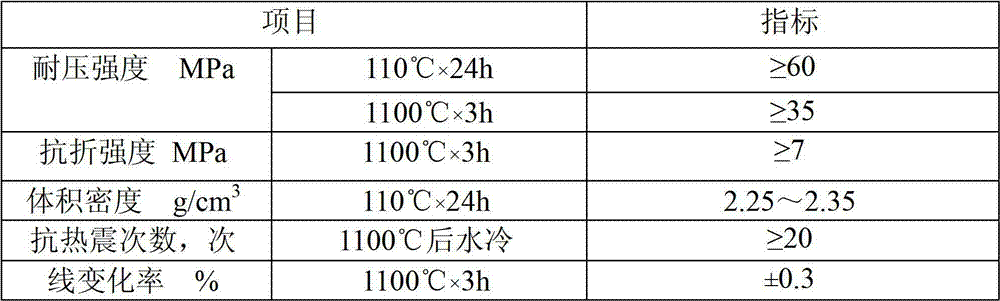

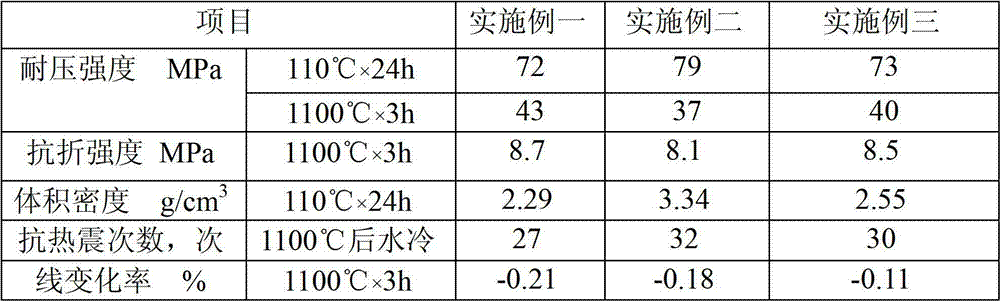

[0070] According to the various performance indexes of the spray paint that above-mentioned embodiment makes are shown in the table below:

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com