Method for reducing secondary electron emission coefficient on silver-plated surface of aluminum alloy

A secondary electron emission, aluminum alloy technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of inapplicability, high microwave transmission loss, large structure size, etc., to achieve loss characteristics and transmission performance is small, the secondary electron emission coefficient is reduced, and the effect of reducing the secondary electron emission coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

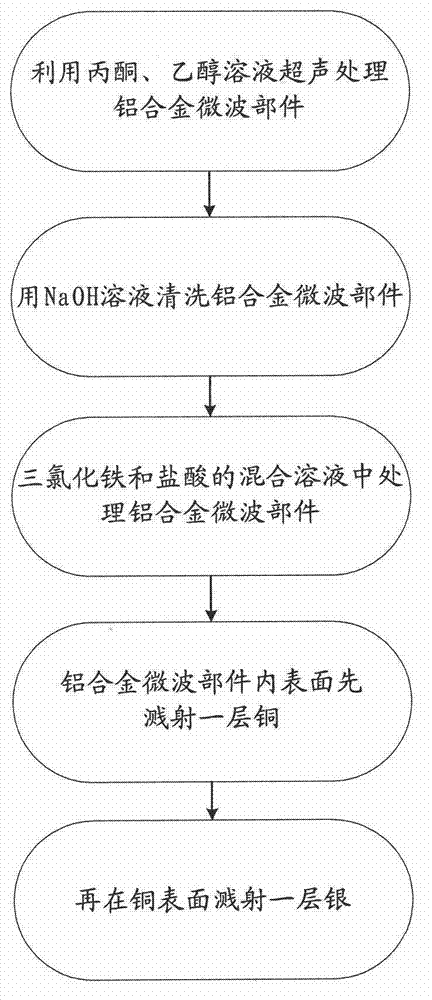

[0020] 1. Clean aluminum alloy microwave components

[0021] Put the machined aluminum alloy microwave components into the acetone solution for 10 minutes of ultrasonic cleaning, and then put them into the ethanol solution for 10 minutes of ultrasonic cleaning.

[0022] 2. Pretreatment of aluminum alloy microwave components

[0023] Put the aluminum alloy microwave parts into 50g / L NaOH solution for 1 minute, and control the temperature of the solution within the range of 40 degrees Celsius.

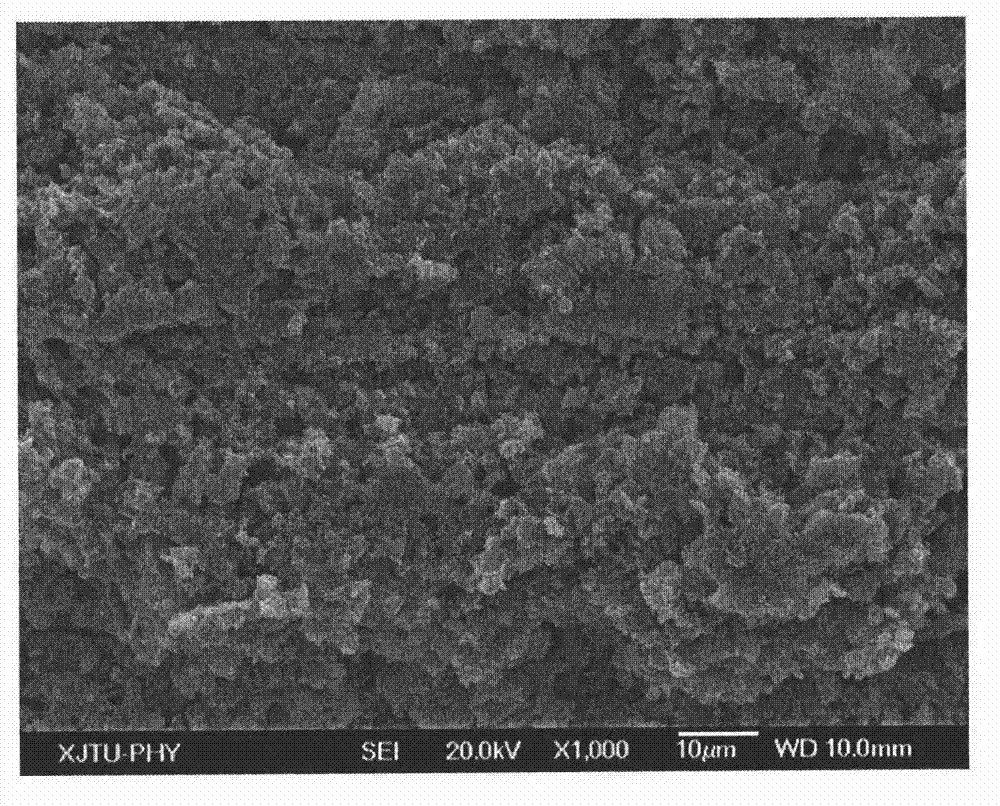

[0024] 3. Corrosion of aluminum alloy microwave components

[0025] Put the aluminum alloy microwave parts into a solution of ferric chloride with a concentration of 5g / L and hydrochloric acid with a concentration of 10g / L for 3 minutes, and the temperature of the solution is 40 degrees Celsius.

[0026] 4. Sputtering of aluminum alloy microwave components

[0027] Sputtering a layer of copper and then sputtering a layer of silver on the surface of the corroded aluminum alloy microwav...

Embodiment 2

[0029] 1. Clean aluminum alloy microwave components

[0030] Ultrasonic cleaning of aluminum alloy microwave parts in acetone solution for 10 minutes, and then ultrasonic cleaning in ethanol solution for 10 minutes.

[0031] 2. Pretreatment of aluminum alloy microwave components

[0032] Put the aluminum alloy microwave parts into 50g / L NaOH solution for 1 minute, and control the temperature of the solution within the range of 40 degrees Celsius. Apply protective glue on the non-treated working surface, and hang the aluminum alloy microwave components.

[0033] 3. Corrosion of aluminum alloy microwave components

[0034] Put the aluminum alloy microwave component coated with protective glue into a solution of ferric chloride with a concentration of 5g / L and hydrochloric acid with a concentration of 10g / L for 3 minutes, and the temperature of the solution is 40 degrees Celsius. After the corrosion is completed, remove the protective glue on the surface, and then clean the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com