Collector electrode material, preparation thereof, surface treatment method, and collector comprising same

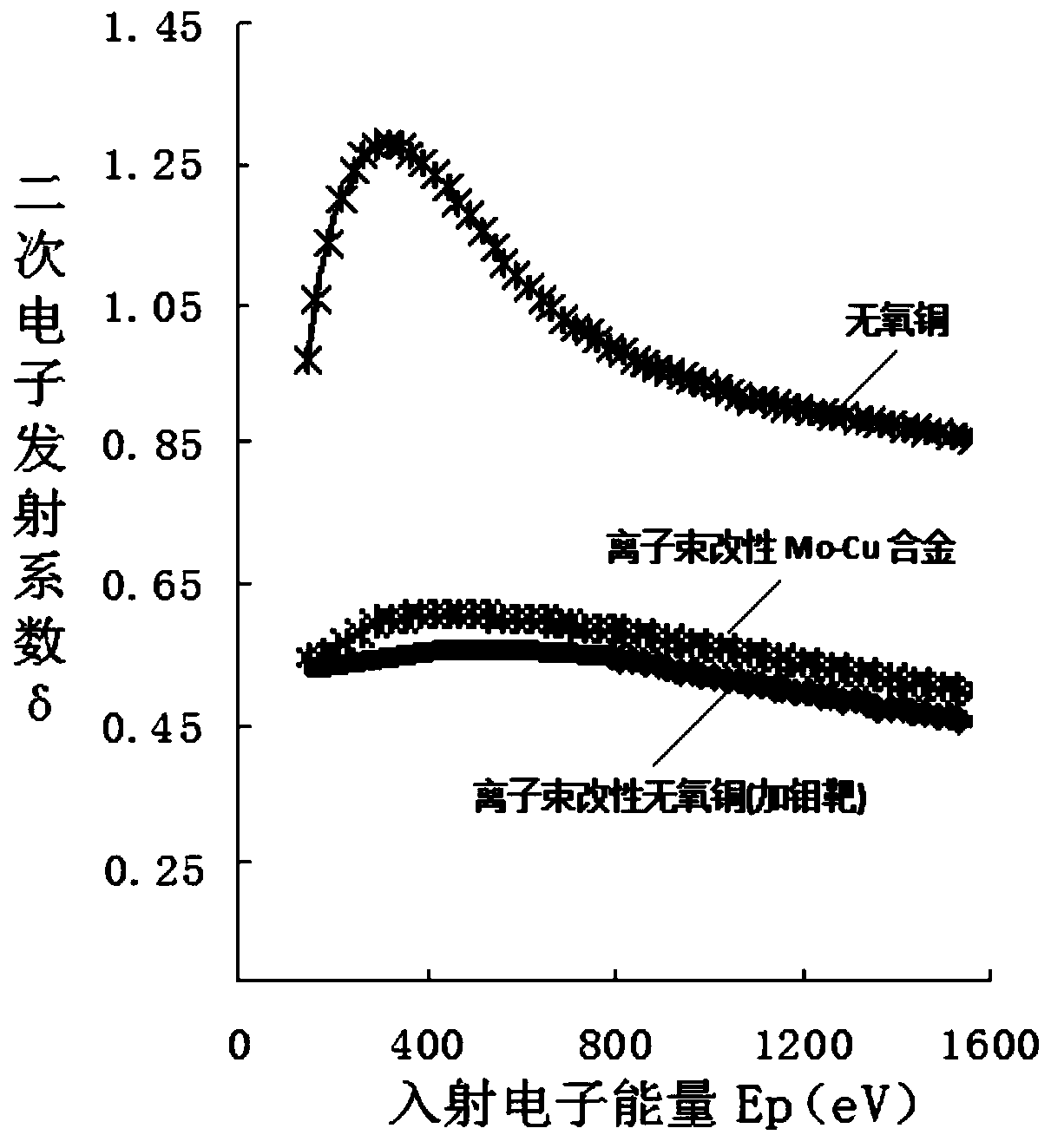

A technology for electrode materials and collectors, which is applied in the field of collector electrode materials, can solve the problems such as the inability to reduce the secondary electron coefficient of the collector, and achieve the effects of reducing the secondary electron emission coefficient, uniform shape, and high use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention also provides the preparation method of above-mentioned collector electrode material, and this preparation method comprises the following steps:

[0039] Mix copper powder and refractory metal powder, ball mill, sieve, mold, and press to form a green body;

[0040] The green body is sintered in a hydrogen atmosphere, the sintering temperature is 800-900°C, and the holding time is more than 2h;

[0041] The green body is further sintered in vacuum, the sintering temperature is 1000-1050° C., and the holding time is more than 2 hours, so as to obtain the electrode material of the multi-stage step-down collector.

[0042] It can be understood that in the preparation method, in the mixture of copper powder and refractory metal powder, the mass percentage of copper powder is 95-98wt%, and the mass percentage of refractory metal is 2-5wt%. Sintering the pressed body at a specific temperature in a hydrogen atmosphere and in a vacuum suc...

Embodiment 1

[0055] A preparation method of a collector electrode material, comprising the steps of:

[0056] 1) Weigh high-purity copper powder and molybdenum powder according to the mass ratio of 95:5, put them together with refractory metal molybdenum balls into a nylon mixing container, and ball mill and mix them on a planetary ball mill for 36 hours. Open the mixing container once every 12 hours, scrape off the powder adhering to the container wall, and continue to the next stage of ball milling;

[0057] 2) Grinding and sieving the mixed powder so that the particle size of the copper powder and molybdenum powder is 1-10 μm, loading into a mold, and pressing (cold isostatic pressing) into a green body, and the cold isostatic pressing molding pressure is 200 MPa;

[0058] 3) Put the molded biscuit into a hydrogen furnace for pre-sintering, the sintering temperature is 850°C, and the holding time is 2 hours;

[0059] 4) Put the pre-fired green body into a vacuum furnace for sintering, ...

Embodiment 2

[0064] A preparation method of a collector electrode material, comprising the steps of:

[0065] 1) Weigh high-purity copper powder and tungsten powder according to the mass ratio of 97:3, put them together with refractory metal tungsten grinding balls into a nylon mixing container, and ball mill and mix them on a planetary ball mill for 36 hours. Open the mixing container once every 12 hours, scrape off the powder adhering to the container wall, and continue to the next stage of ball milling;

[0066] 2) Grinding and sieving the mixed powder so that the particle size of the copper powder and molybdenum powder is 1-10 μm, loading into a mold, and pressing (cold isostatic pressing) into a green body, and the cold isostatic pressing molding pressure is 280 MPa;

[0067] 3) Put the molded biscuit into a hydrogen furnace for pre-sintering, the sintering temperature is 820°C, and the holding time is 2.5 hours;

[0068] 4) Put the pre-fired green body into a vacuum furnace for sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com