Film containing nested micro trap structure and preparation method thereof

A nesting and trapping technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems such as high-power microwave system not working normally, component surface erosion, affecting equipment performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

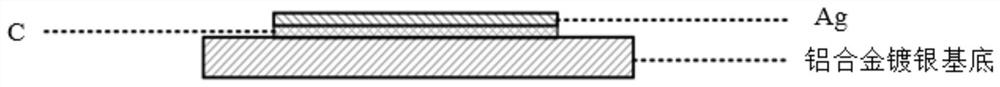

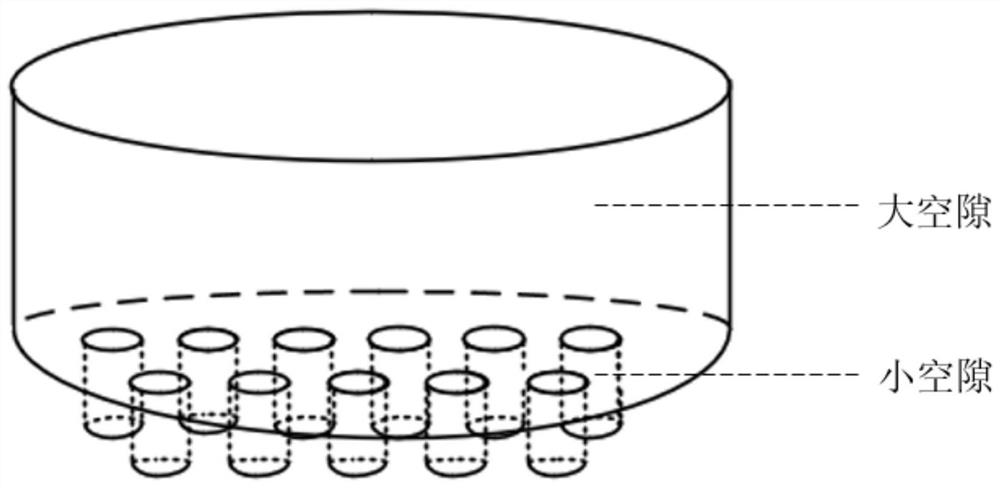

[0036] In order to obtain a high-quality secondary electron suppression film with a nested micro-trap structure, we choose C material as the lower material film and Ag material as the upper material film. The reason for choosing these two materials is due to the atomic radius of C Smaller, the covalent radius is also smaller when forming a thin film, and the Ag atom has a larger atomic radius than the C atom, and the covalent radius is also larger when forming a thin film, so that it is easier to make the lower layer with a smaller atomic gap when coating The material film and the upper material film with a larger atomic gap form a nested trap structure with higher quality. For the substrate, we choose the aluminum alloy silver-plated material commonly used in space microwave materials.

[0037] A method for preparing a thin film containing a nested micro-trap structure, specifically comprising the following steps:

[0038] Step 1: Cleaning, an aluminum alloy silver-plated su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com