Retainer for tapered roller bearing and bearing with retainer

A tapered roller bearing and bearing cage technology, applied in the direction of roller bearings, bearing components, shafts and bearings, can solve problems such as raceway contact and bearing failure, and achieve increased clearance, increased strength, and increased flexibility. and longevity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

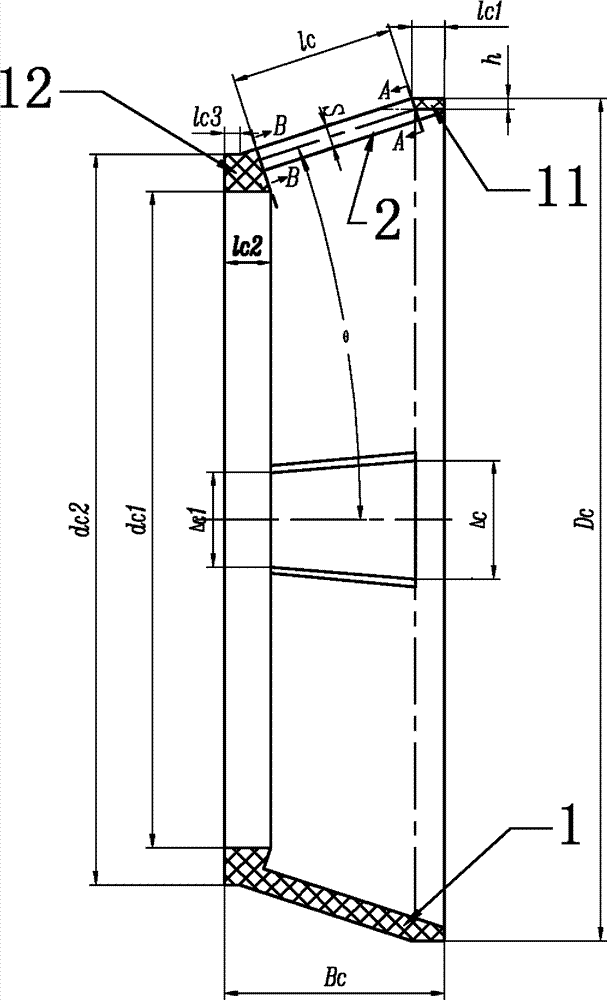

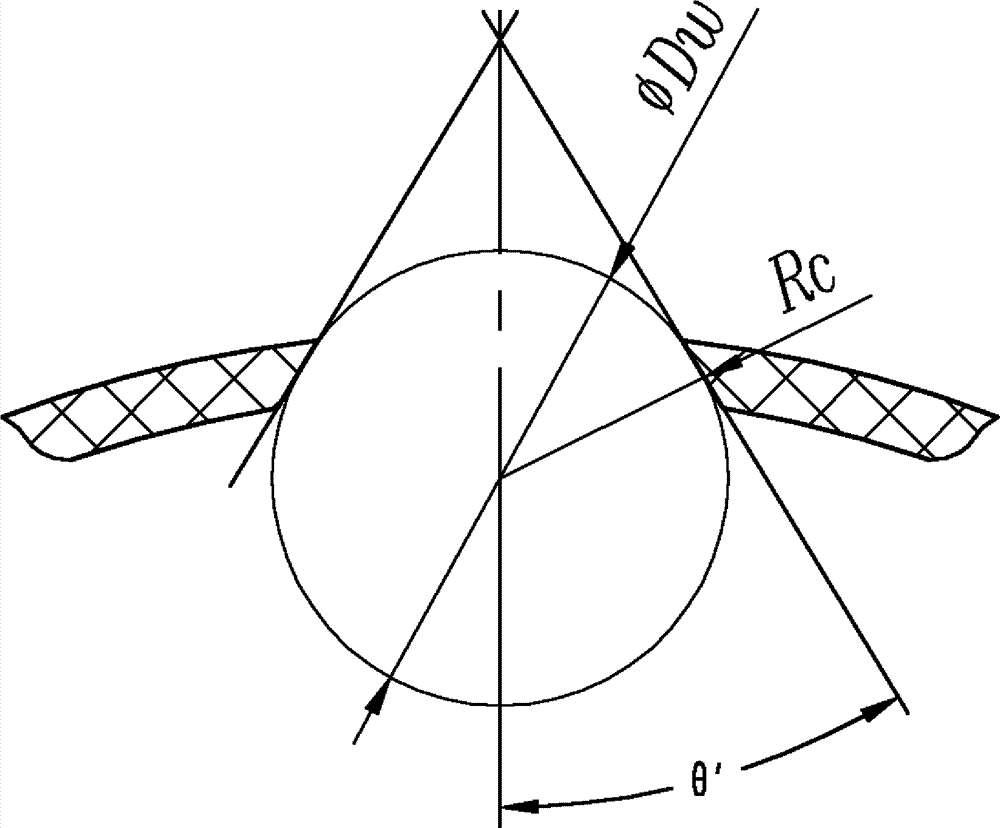

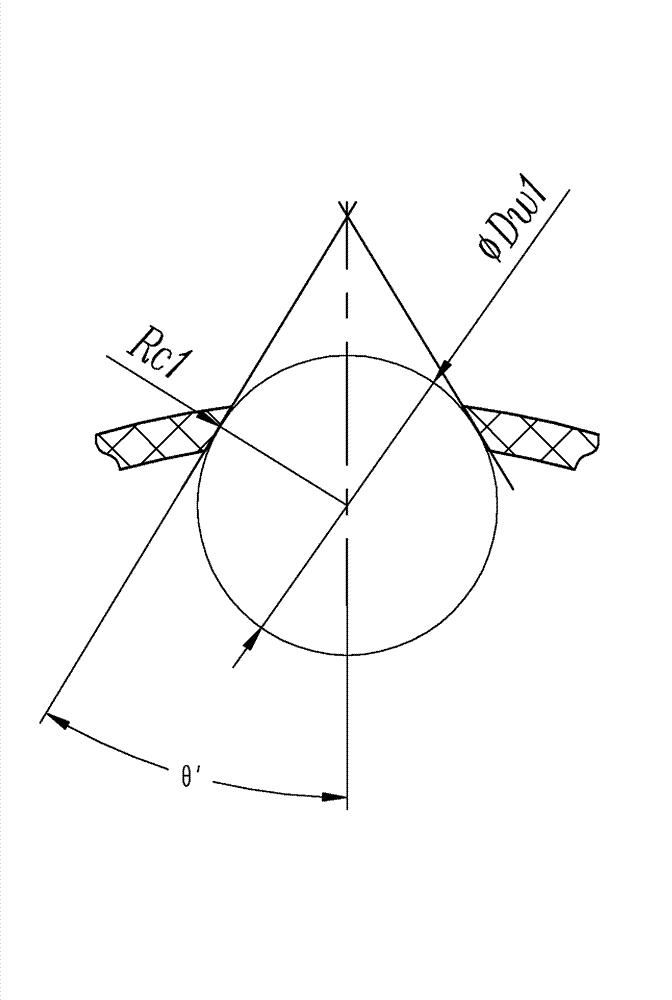

[0021] An embodiment of a cage for a tapered roller bearing, taking the structure of the 32010 / HV bearing cage as an example (unit: mm): the diameter of the center circle of the large and small heads of the tapered rollers fD w , fD w1 The values are 6.89 and 6.18, and the cage structure is as follows Figure 1-3 As shown, it includes a frame body 1 made of polyetheretherketone composite material. The frame body includes a large end ring 11 and a small end ring 12 arranged side by side in the axial direction. The outer peripheral surface of the large end ring 11 is in line with the bearing The cylindrical surface parallel to the axis of the cage, the outer diameter of the big end ring D C =4.2, the radial thickness of the big end ring 11 h=1.30, the axial width L of the big end ring C1 =2, the outer peripheral surface of the small end ring 12 has a cylindrical surface parallel to the axis of the bearing cage from its front end to the rear end, the front end surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com