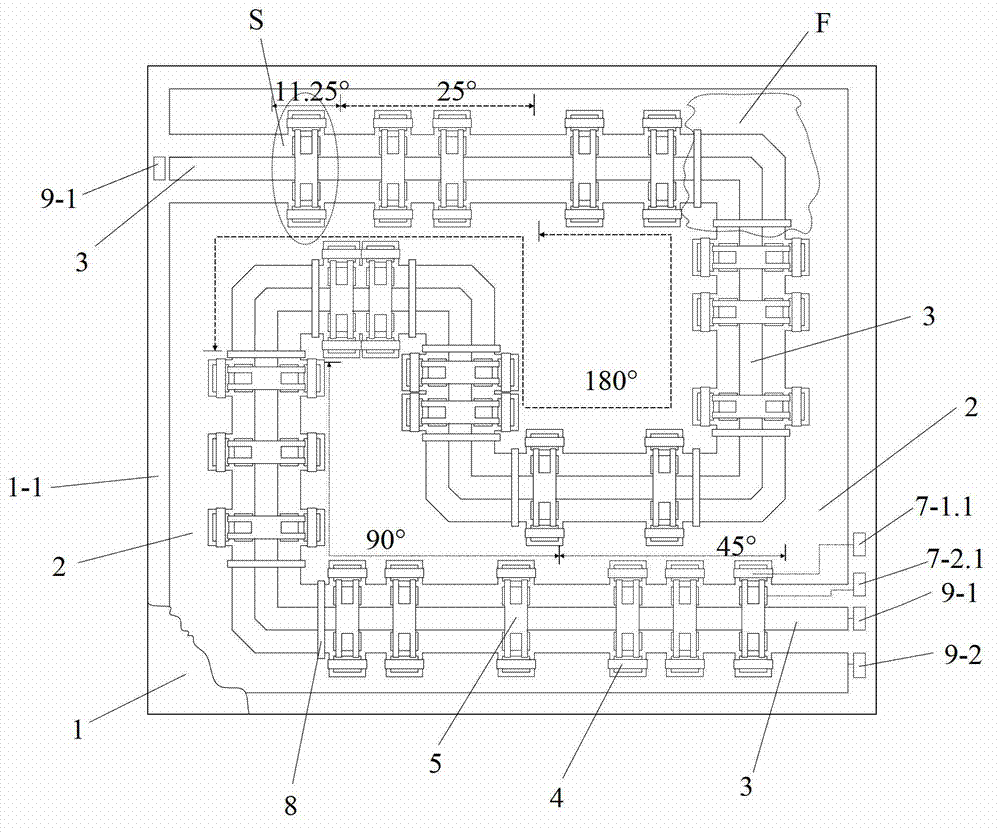

Five-bit X wave band phase shifter

A phase shifter and X-band technology, which is applied in the field of five-bit X-band miniaturized phase shifters, can solve the problems of phase shifter packaging difficulty, high production cost, poor strength and stability, and limited application range, etc., to eliminate Instability, high strength and stability, the effect of reducing packaging difficulty and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

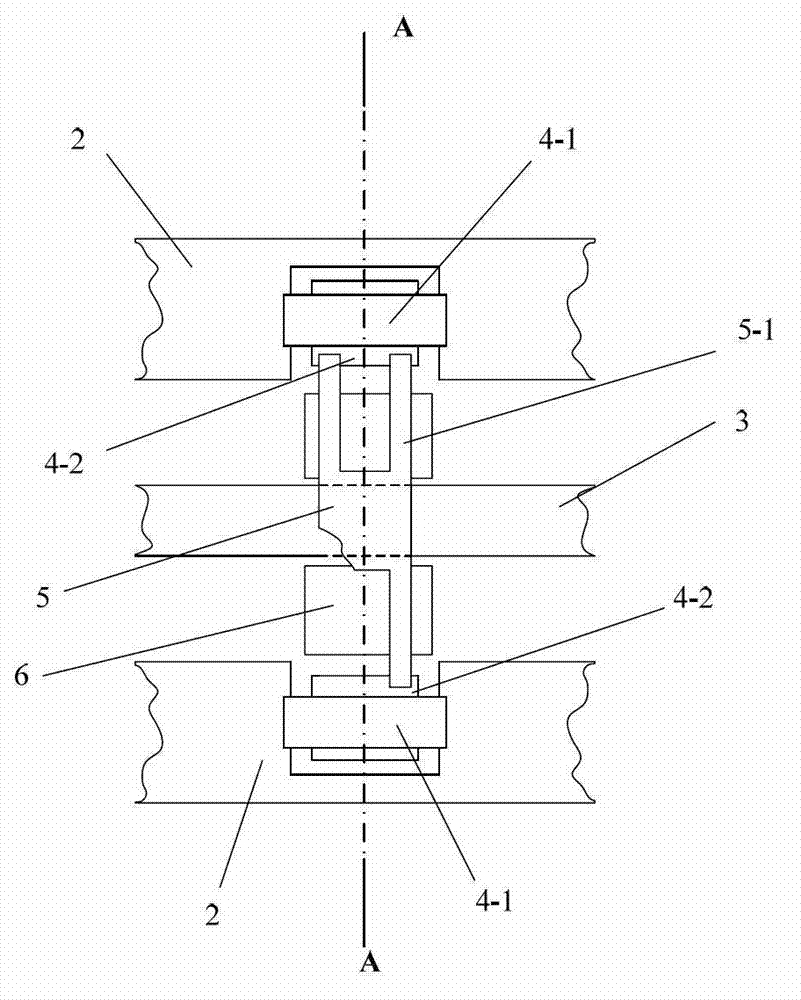

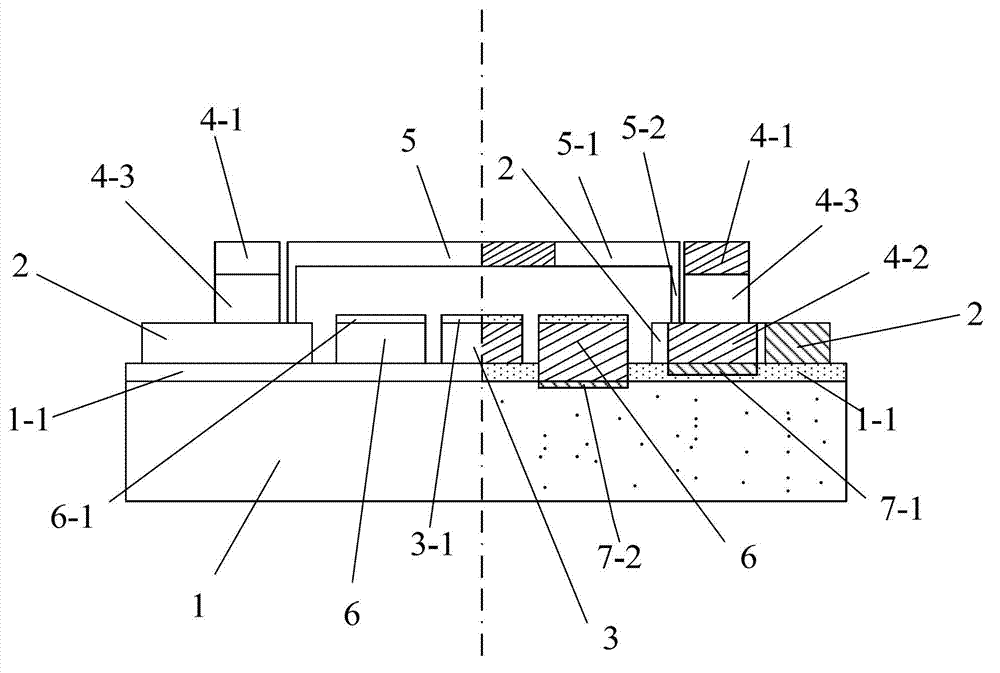

[0013] The substrate 1 of the present invention (length×width×thickness) 2.68×1.45×0.52mm) is made of silicon, and the material of the substrate insulating layer 1-1 is SiO 2 , the thickness is 1 μm; the width of CPW signal line 3 is 50 μm, the distance between both sides and CPW ground wire 2 is 106 μm, the thickness of CPW signal line 3 and CPW ground wire 2 are both 2 μm, and the material is copper (CU), (CPW signal line) The thickness of the insulating layer 3-1 is 0.5 μm; the length and width of the upper plate 4-1 and the lower plate 4-2 of the MAM capacitor are 155 μm and 110 μm respectively, and the thickness is 1.5 μm. The upper pole of the MAM capacitor The height of the plate 4-1 is 2.3 μm; the height of the MEMS switch 5 is 2.3 μm, fixed on the lower plate of the MAM capacitor through the support rod 5-2, the length of the MEMS switch beam 5-1 is 262 μm, the thickness is 0.5 μm, The width is 80 μm, and the width of the rectangular process hole at both ends is 60 μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com