A method for manufacturing a high-strength and light-weight integral hydrophobic xonotlite thermal insulation and fireproof board

A technology of xonotlite and its production method, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve problems such as difficulty in fully forming xonotlite, failure of organic glue, and decline in fire resistance, and achieve light bulk density and loss of strength Small, uniform material without bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for manufacturing a high-strength and light-weight integral hydrophobic xonotlite thermal insulation and fireproof board, comprising the following steps:

[0024] 1) After mixing the siliceous raw material and the calcareous raw material according to the Ca / Si ratio (molar ratio) of 0.9, inject it into a dynamic reaction kettle, use superheated steam at 250°C, and steam pressure at 2.0Mpa to synthesize for 3 hours to obtain hard silicon calcium Stone slurry, adding reinforcing fiber;

[0025] 2) Remove excess water from the xonotlite slurry obtained in step 1), and add 0.1% inorganic glue (by weight ratio of slurry to inorganic glue);

[0026] 3) Adding 0.1% reactive silicone water repellent to the xonotlite slurry obtained in step 2) to form an interfacial combination with the slurry;

[0027] 4) The xonotlite slurry prepared in the above step 3) is molded and dried to obtain a xonotlite plate with uniform material, high strength, light weight and completely ...

Embodiment 2

[0030] A method for manufacturing a high-strength and light-weight integral hydrophobic xonotlite thermal insulation and fireproof board, comprising the following steps:

[0031] 1) After mixing the siliceous raw material and the calcareous raw material according to the Ca / Si ratio (molar ratio) of 1.1, pour it into a dynamic reaction kettle, and use 400°C superheated steam at a steam pressure of 2.7MPa to synthesize it for 8 hours to obtain hard silicon calcium Stone slurry, adding reinforcing fiber;

[0032] 2) Remove excess water from the xonotlite slurry obtained in step 1), and add 8% inorganic glue (by weight ratio of slurry to inorganic glue);

[0033] 3) Adding 8% reactive silicone water repellent to the xonotlite slurry obtained in step 2) to form an interfacial combination with the slurry;

[0034] 4) The xonotlite slurry prepared in the above step 3) is molded and dried to obtain a xonotlite plate with uniform material, high strength, light weight and completely hy...

Embodiment 3

[0037] A method for manufacturing a high-strength and light-weight integral hydrophobic xonotlite thermal insulation and fireproof board, comprising the following steps:

[0038] 1) After mixing the siliceous raw material and the calcareous raw material according to the Ca / Si ratio (molar ratio) of 1.0, inject it into a dynamic reaction kettle, and use 320°C superheated steam at a steam pressure of 2.4Mpa to synthesize it for 5 hours to obtain xonotlite Slurry, adding reinforcing fibers;

[0039] 2) Remove excess water from the xonotlite slurry obtained in step 1), and add 5% inorganic glue (by weight ratio of slurry to inorganic glue);

[0040] 3) Adding 6% of reactive silicone water repellent to the xonotlite slurry obtained in step 2) to form an interfacial combination with the slurry;

[0041] 4) The xonotlite slurry prepared in the above step 3) is molded and dried to obtain a xonotlite plate with uniform material, high strength, light weight and completely hydrophobic. ...

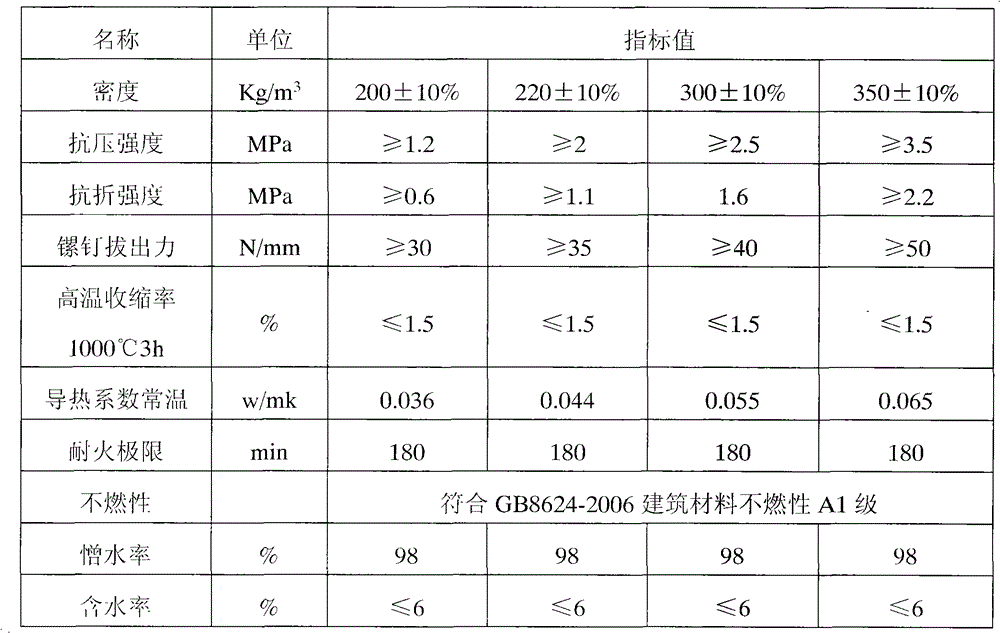

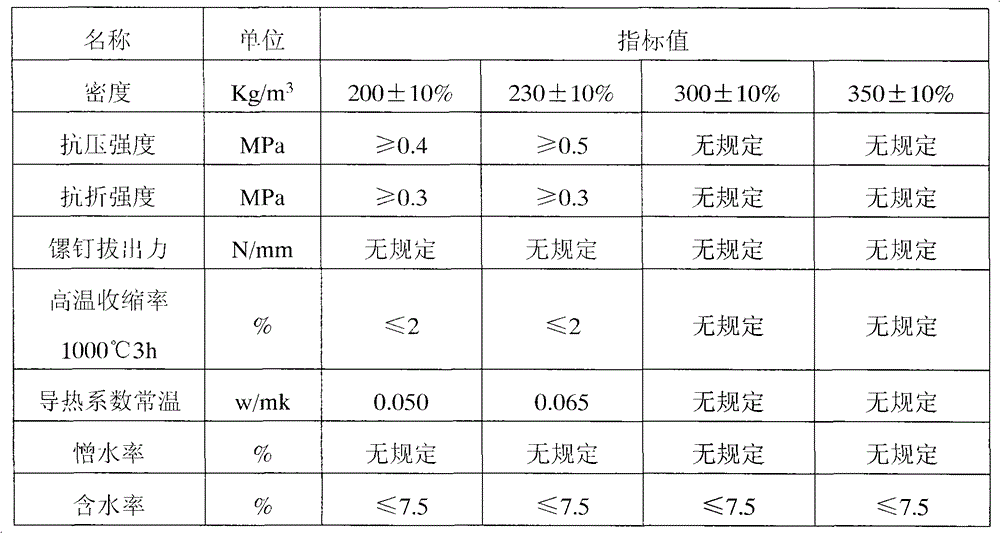

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com