Full-cycling technology for vanadium smelting wastewater

A full cycle, waste water technology, applied in water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as failure to meet discharge standards, complicated operation, corrosion passivation, etc. Achieve the effects of saving water resources and industrial salt, simple and convenient operation, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

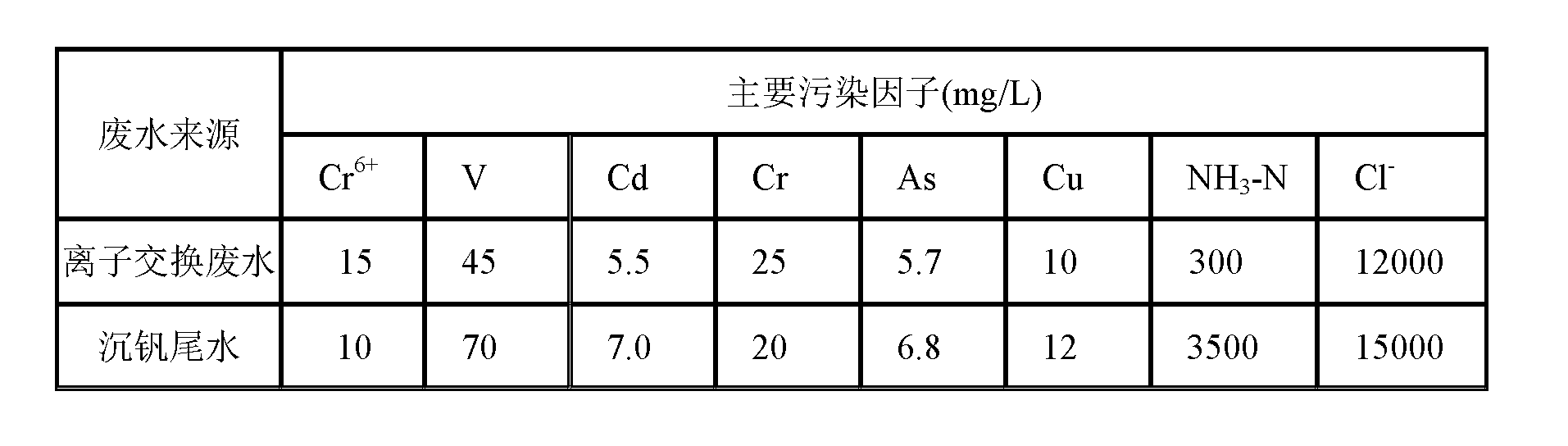

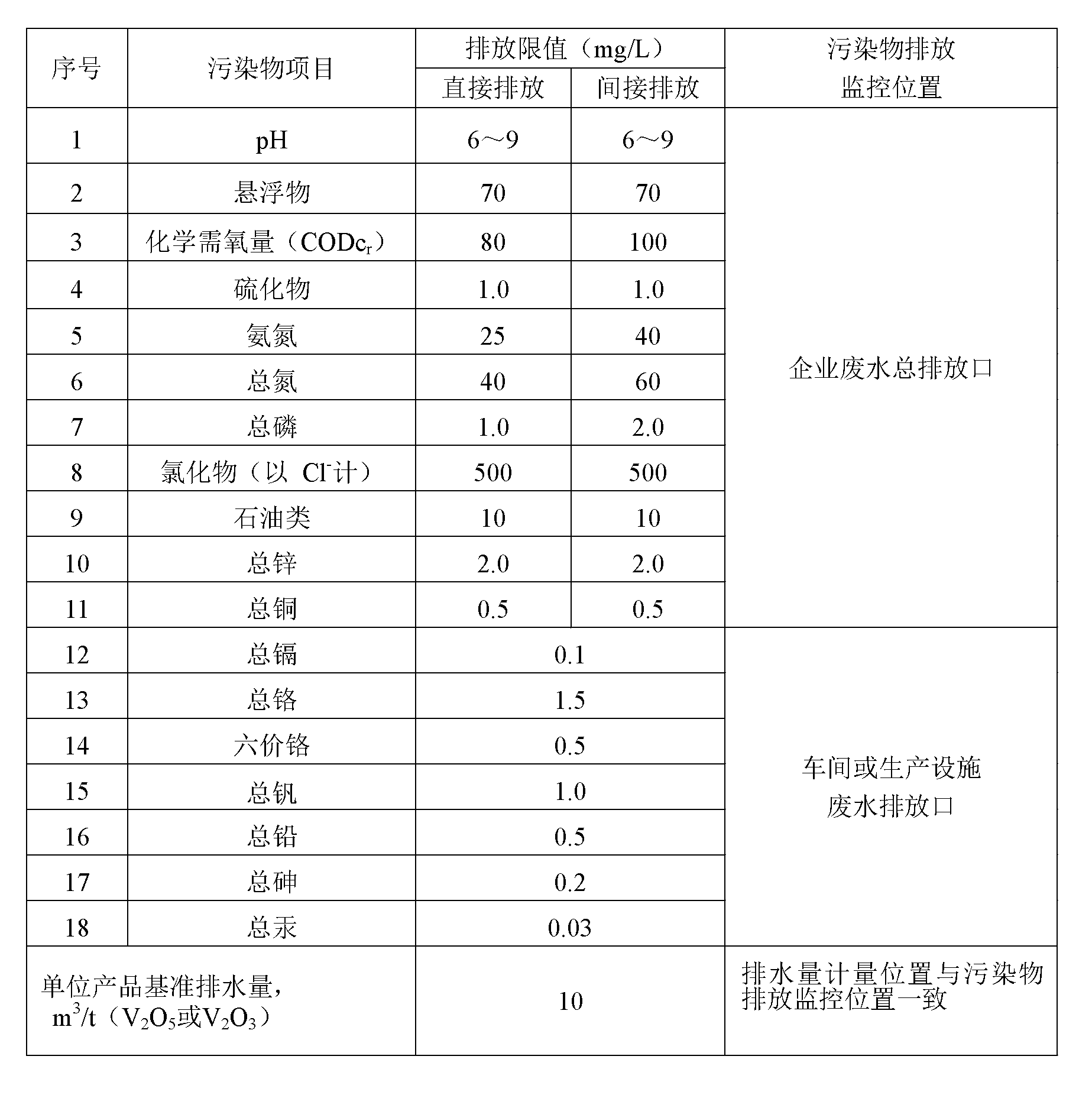

[0019] The following is illustrated by an implementation example: in the actual water sample of a certain vanadium extraction plant in Hunan, the concentration of the main heavy metal ions is shown in Table 1. The vanadium extraction wastewater is weakly alkaline, with a pH value of 6~9, and the concentration of the first type of pollutants in the wastewater V, Cr 6+ , Cd, Cr, As, Cu, NH 3 -N, Cl - The content is relatively high, which is much higher than the water pollution discharge limit of newly-built vanadium mining enterprises in the "Vadium Industry Pollutant Discharge Standard" (GB26452-2011). The specific indicators are shown in Table 2.

[0020] Table 1 Main Pollutant Components in Vanadium Extraction Tail Liquid

[0021]

[0022] Table 2 Pollutant discharge concentration limits and benchmark discharge per unit product of new enterprises

[0023]

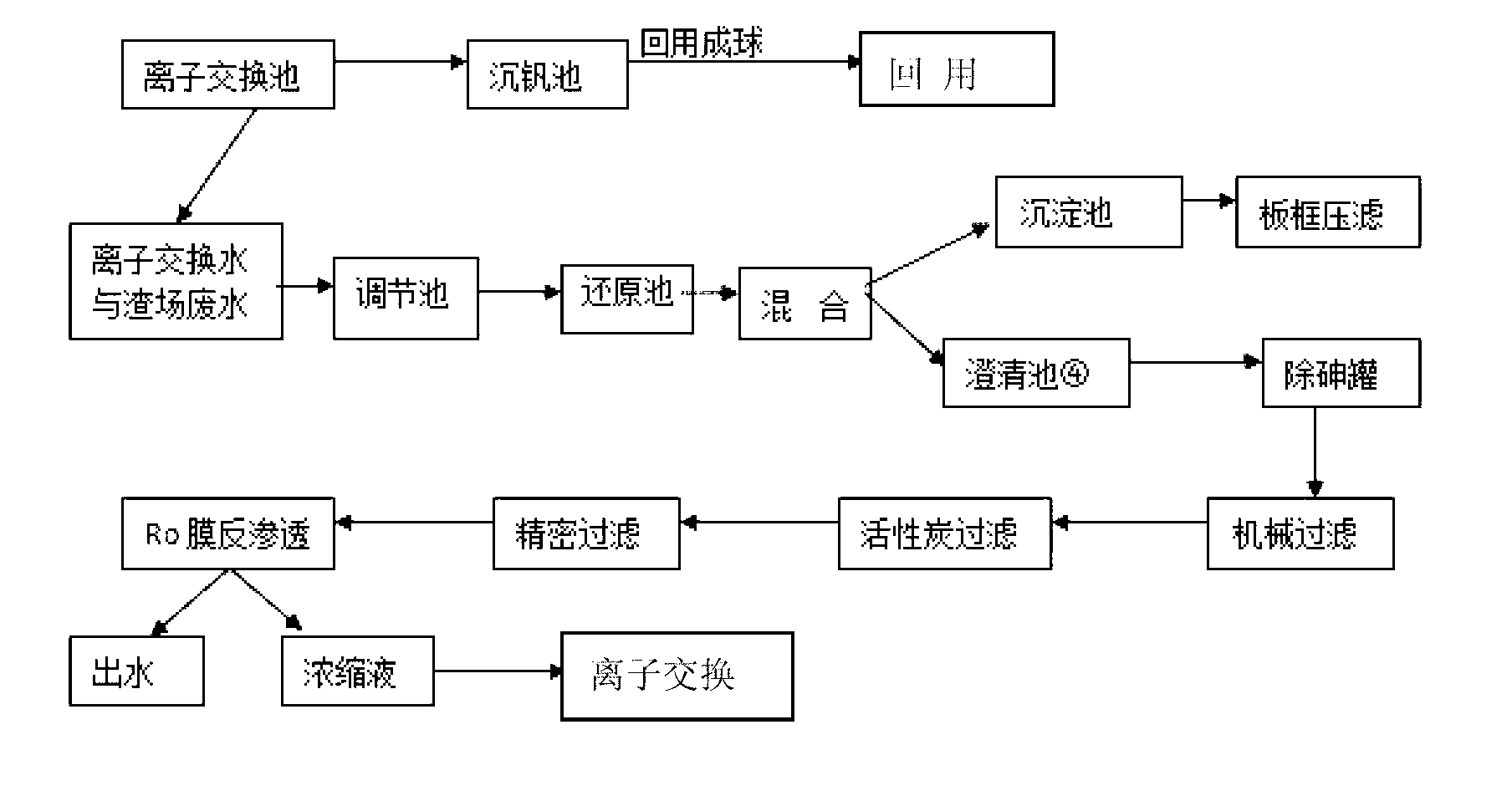

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com