Cable suspending type air partial reverse circulating motor mechanical core bit

A reverse-circulation, suspended technology, applied in drilling equipment, earthwork drilling, extraction of undisturbed core devices, etc., to achieve the effects of ingenious design, pollution avoidance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

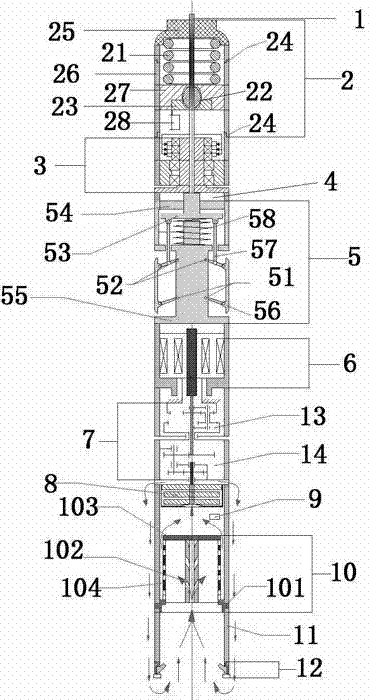

[0038] The winch controls the retraction of the armored cable 1, thereby lifting and lowering the drilling tool. When the drilling tool is lowered to a certain depth, the motor 6 in the drilling tool starts to work, and the motor 6 reduces the rotation speed of the drilling tool to a reasonable value through a transmission 7. , rotary cutting ice layer; because the rotation speed of the vacuum pump 8 is relatively high, the rotation speed of the motor 6 needs to be raised to a certain value through another transmission 7, and the high-speed rotation generates negative pressure, forms an airflow, sucks ice chips, and cools the drill bit. During the drilling process, the airflow generated by the rotation of the vacuum pump 8 enters the ice core pipe 11 from the nozzle of the drill bit, flows into the vacuum pump 8 after passing through the ice debris chamber 10, and then shoots at high speed from the outlet of the vacuum pump 8 to the gap between the hole wall and the drilling too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com