Electrolytic degreasing ultrasonic cleaner

An electrolytic degreasing and electrolytic cleaning technology, which is applied in the electrolytic process, electrolytic components, cleaning methods and appliances, etc., can solve the problems of frequent replacement of cleaning solvents, low service life of cleaning tanks, and easy splashing of solutions, etc., and achieves simple structure, Easy to operate and use, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

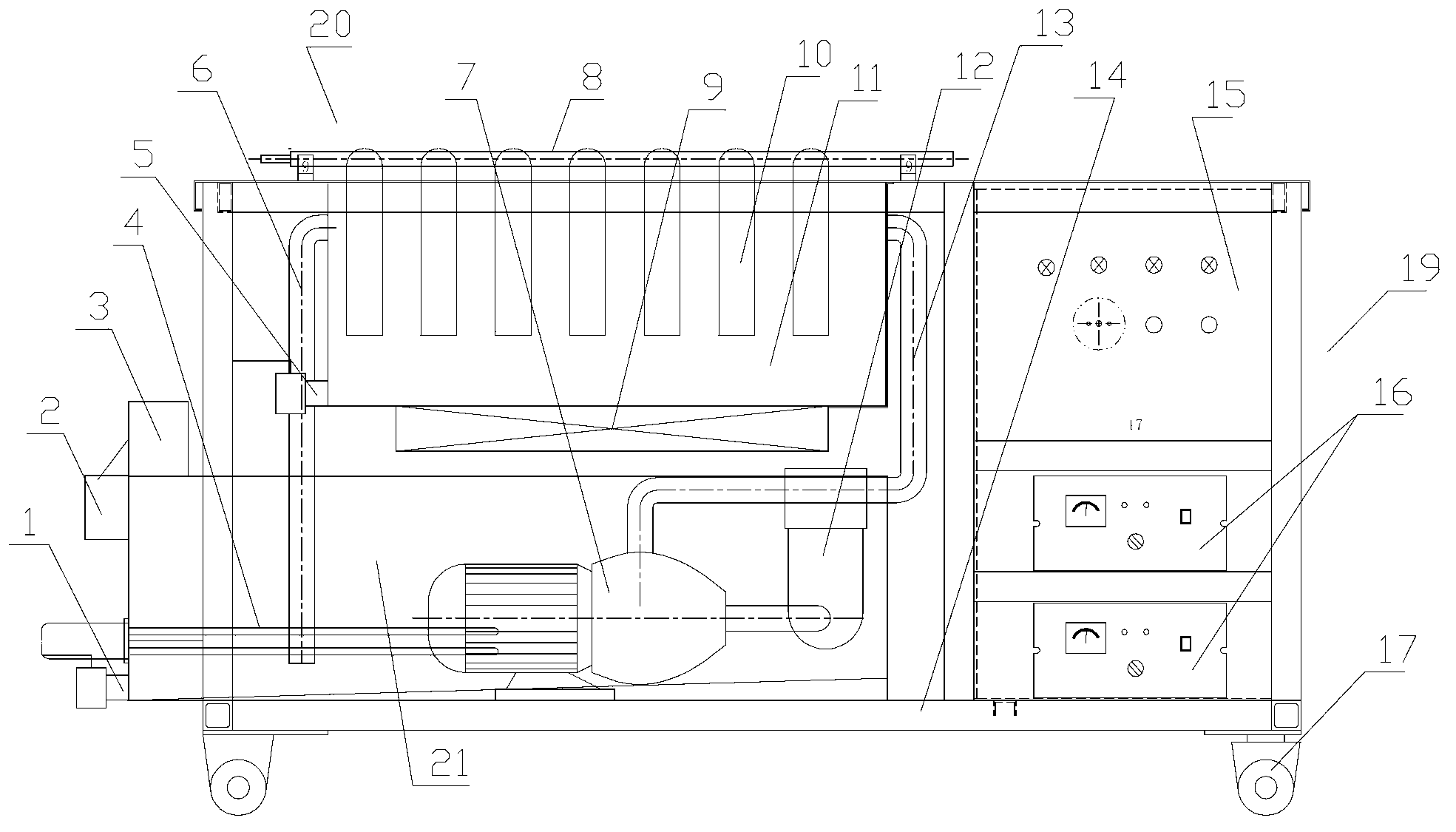

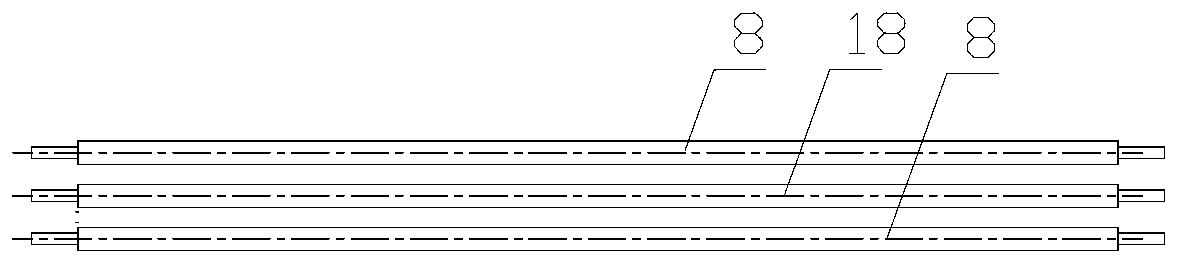

[0015] Examples 1 and 2. An electrolytic degreasing ultrasonic cleaning machine, comprising a frame 14, a box body 20 is arranged on the frame 14, an electric control cabinet 19 is arranged on the frame on one side of the box body 20, and a liquid storage filter tank 21 is arranged in the box body 20 , the top of the liquid storage filter tank 21 is provided with an electrolytic cleaning tank 11, the bottom of the electrolytic cleaning tank 11 is provided with an ultrasonic transducer 9, and some anode electrode copper rods 18 and some cathode electrode copper rods 8 are horizontally placed on the top of the electrolytic cleaning tank, and the anode electrode copper rods 8 Rods 18 and cathode electrode copper rods 8 are alternately arranged, and a plurality of cathode electrode plates 10 are vertically installed on the cathode electrode copper rods 8, a circulating water pump 7 is provided in the liquid storage filter tank 21, and a side of the electrolytic cleaning tank 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com