Fine metal powder atomizing spray nozzle with molten metal easily flowing out

A technology of atomizing nozzles and metal powders, which is applied in the field of fine metal powder atomizing nozzles, can solve the problems of shortening the length of the catheter, reducing the efficiency of atomization, and affecting the nozzle, so as to overcome the plugging phenomenon and improve the fog Improve efficiency and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

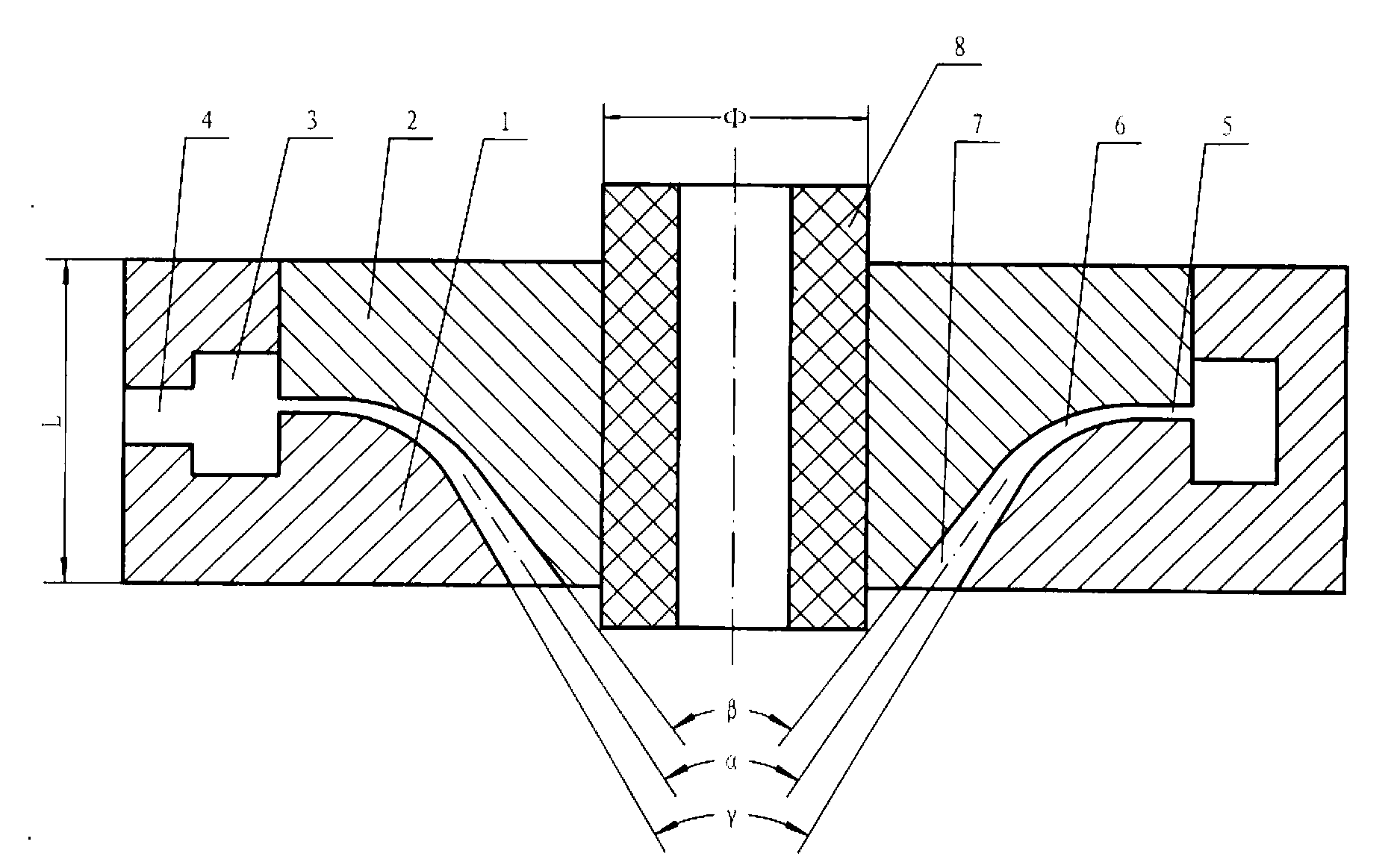

[0033] use figure 1In the nozzle structure shown, the injection angle is 55°, the length of the straight expansion section is 5 mm, the outer diameter φ of the catheter 8 is 15 mm, the inner diameter is 4.0 mm, and the length inside the nozzle is 30 mm. 304L stainless steel was used as the atomization object to carry out the atomization test of the powder, the test alloy was 50kg, the atomization temperature was 1600°C, and the atomization pressure was 4.5MPa. After atomization, use a standard analytical sieve to measure the particle size of the powder. Among the atomized powder, the proportion of powder with a particle size of less than 150 μm (-100 mesh) is 95.0%, and the proportion of powder with a particle size of less than 45 μm (-320 mesh) is 69.3%. , the proportion of powder smaller than 23μm (-600 mesh) is 53.2%, and the average particle size of the powder is d 50 About 20 μm.

example 2

[0035] use figure 1 In the nozzle structure shown, the injection angle is 50°, the length of the straight expansion section is 3mm, the outer diameter of the catheter is 15mm, the inner diameter is 4.0mm, and the length inside the nozzle is 25mm. 17-4ph stainless steel was used as the atomization object to carry out the atomization test of the powder, the test alloy was 50kg, the atomization temperature was 1580°C, and the atomization pressure was 4.5MPa. After atomization, use a standard analytical sieve to measure the particle size of the powder. Among the atomized powder, the proportion of powder with a particle size less than 150 μm (-100 mesh) is 95.5%, and the proportion of powder with a particle size less than 45 μm (-320 mesh) is 75.0%. , the proportion of powder smaller than 23μm (-600 mesh) is 62.3%, and the average particle size of the powder is d 50 About 18 μm.

example 3

[0037] use figure 1 In the nozzle structure shown, the injection angle is 60°, the length of the straight expansion section is 5 mm, the outer diameter of the catheter is 15 mm, the inner diameter is 4.5 mm, and the length inside the nozzle is 25 mm. 316L stainless steel was used as the atomization object to carry out the atomization test of the powder, the test alloy was 50kg, the atomization temperature was 1600°C, and the atomization pressure was 4.5MPa. After atomization, use a standard analytical sieve to measure the particle size of the powder. Among the atomized powder, the proportion of powder with a particle size less than 150 μm (-100 mesh) is 93.5%, and the proportion of powder with a particle size less than 45 μm (-320 mesh) is 70.8%. , the proportion of powder smaller than 23μm (-600 mesh) is 56.5%, and the average particle size of the powder is d 50 About 22 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com