Underwater power and structure mixing pressurization exhaust device

A technology for exhaust devices and exhaust pipes, which is applied in the direction of exhaust devices, mufflers, engine components, etc., and can solve the problems of low control difficulty, water backflow into exhaust pipes, and low requirements for components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

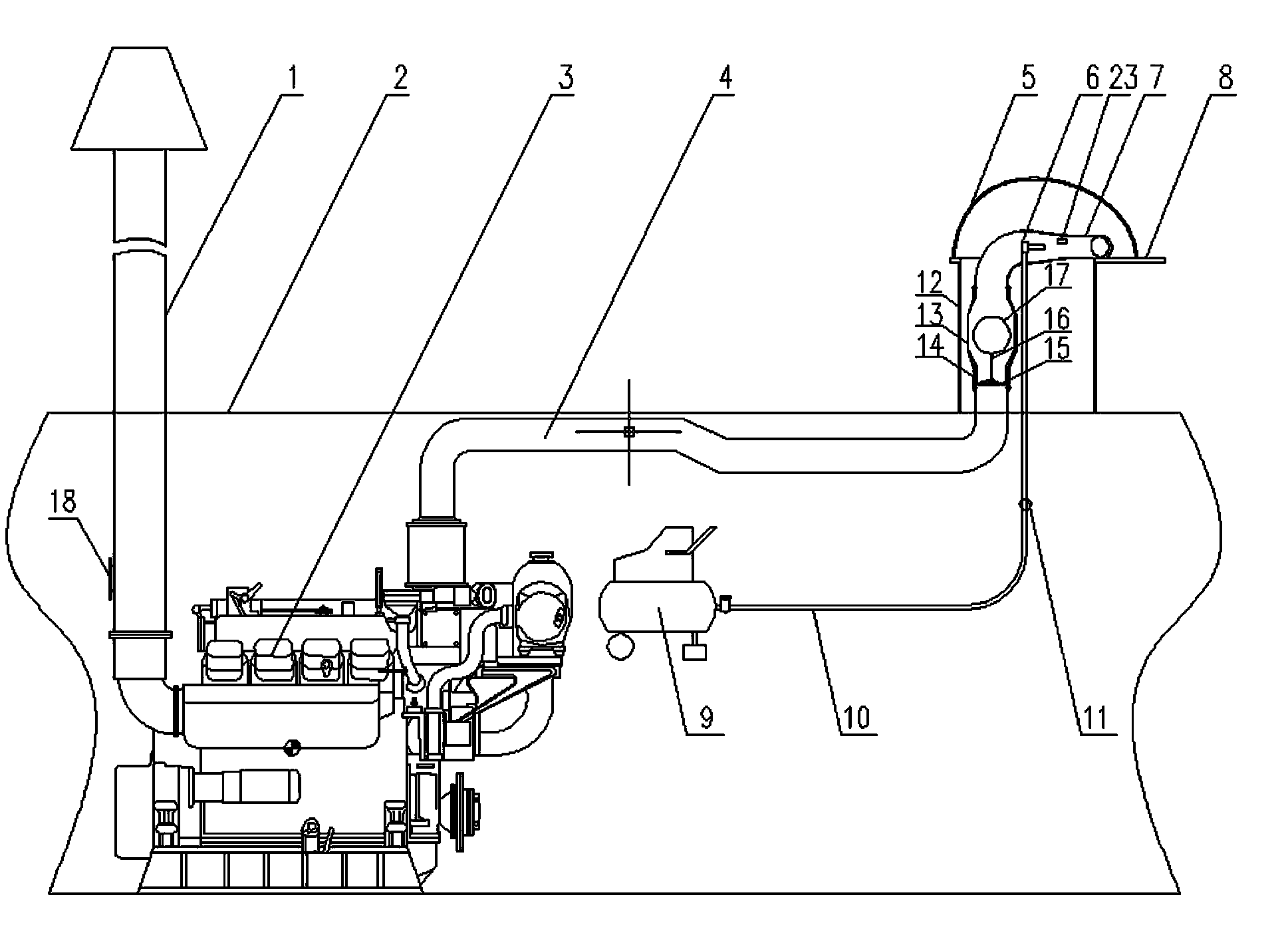

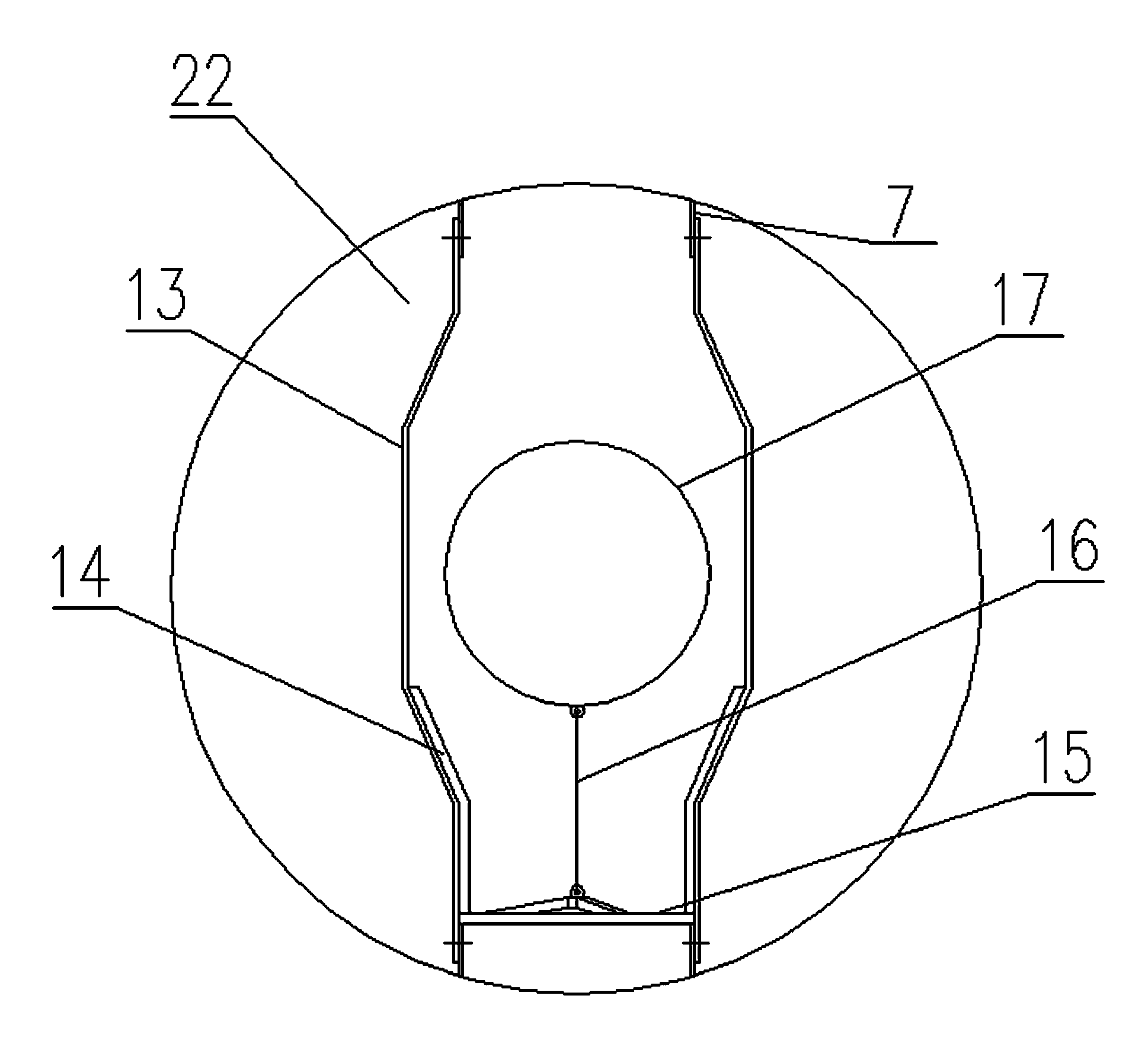

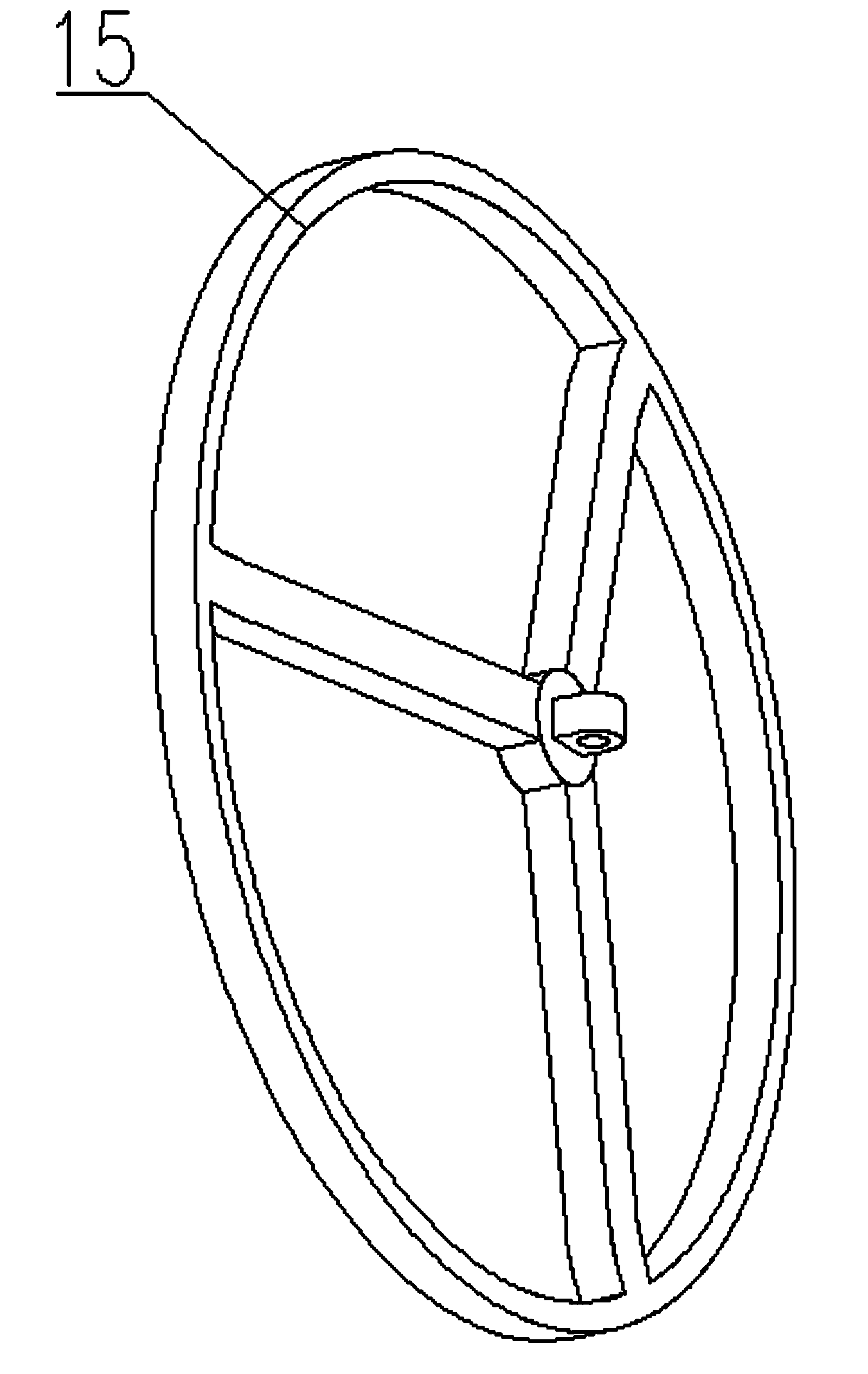

[0022] Such as figure 1 Among them, an underwater hybrid supercharging and exhausting device comprises a vehicle housing 2 connected to the atmosphere, a power system 3 arranged in the vehicle housing 2, an exhaust pipe 4 is arranged on the power system 3, and an exhaust pipe 4 is arranged on the power system 3. The front end of the pipe 4 is provided with an exhaust port, which is characterized in that: the position of the exhaust pipe 4 close to the exhaust port is provided with a one-way exhaust valve 22, and an air compressor 9 for pressurizing the exhaust gas is also provided. The exhaust outlet of the air compressor 9 is located between the one-way exhaust valve 22 and the exhaust port. With this structure, the supercharging and exhausting of the air compressor can be realized without using a special diesel engine, which is suitable for improvement on the basis of the existing common diesel engine.

[0023] Such as figure 1 Among them, the exhaust outlet of the air com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com