Digital adjustable micromirror chip on basis of microfluidics and preparation method thereof

A tunable micromirror and microfluidic technology, applied in the field of digital tunable micromirror chip and its preparation based on microfluidics, can solve problems such as insufficient controllability and insufficient zooming accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

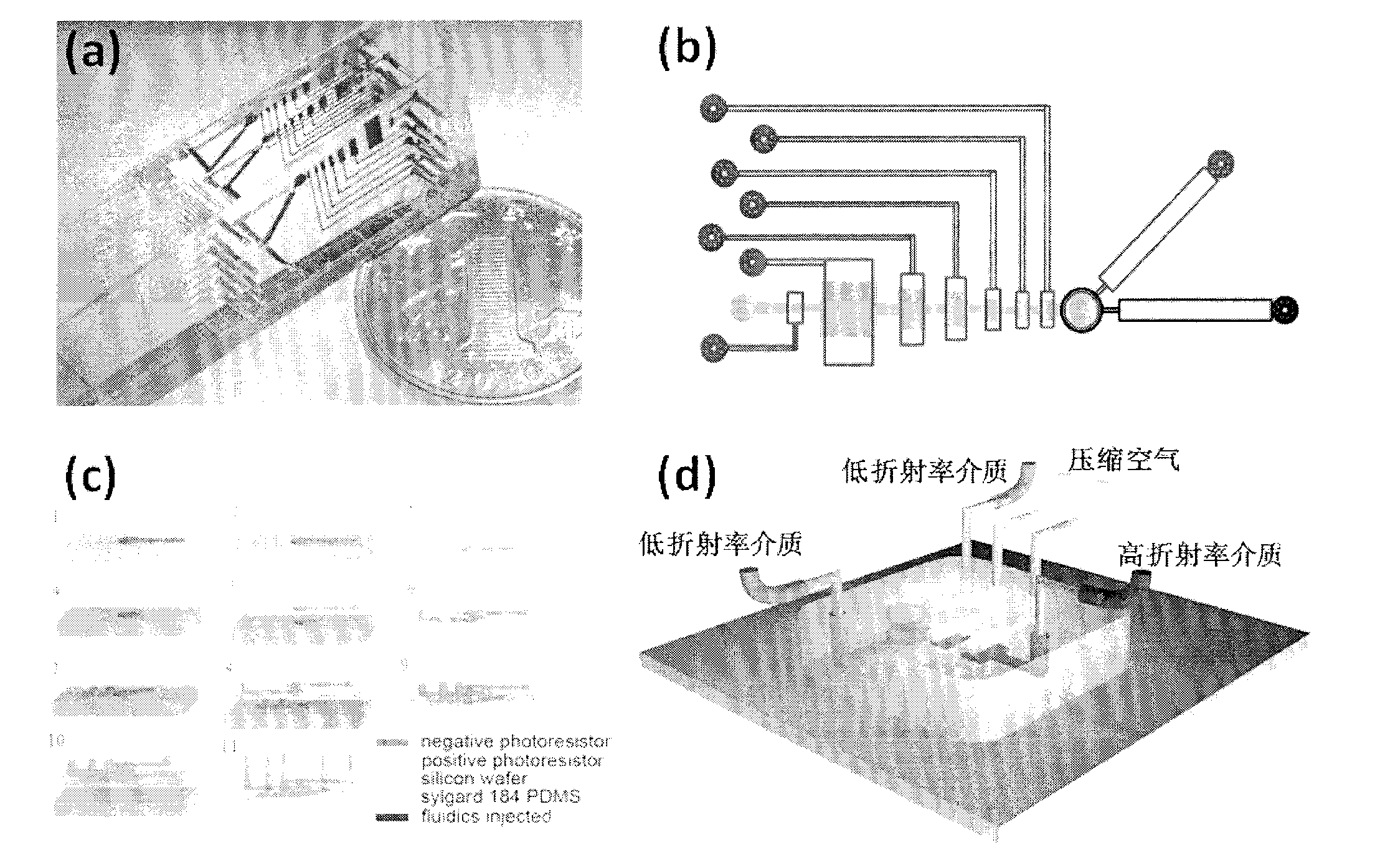

[0024] Composite micromirror chip zoom imaging process.

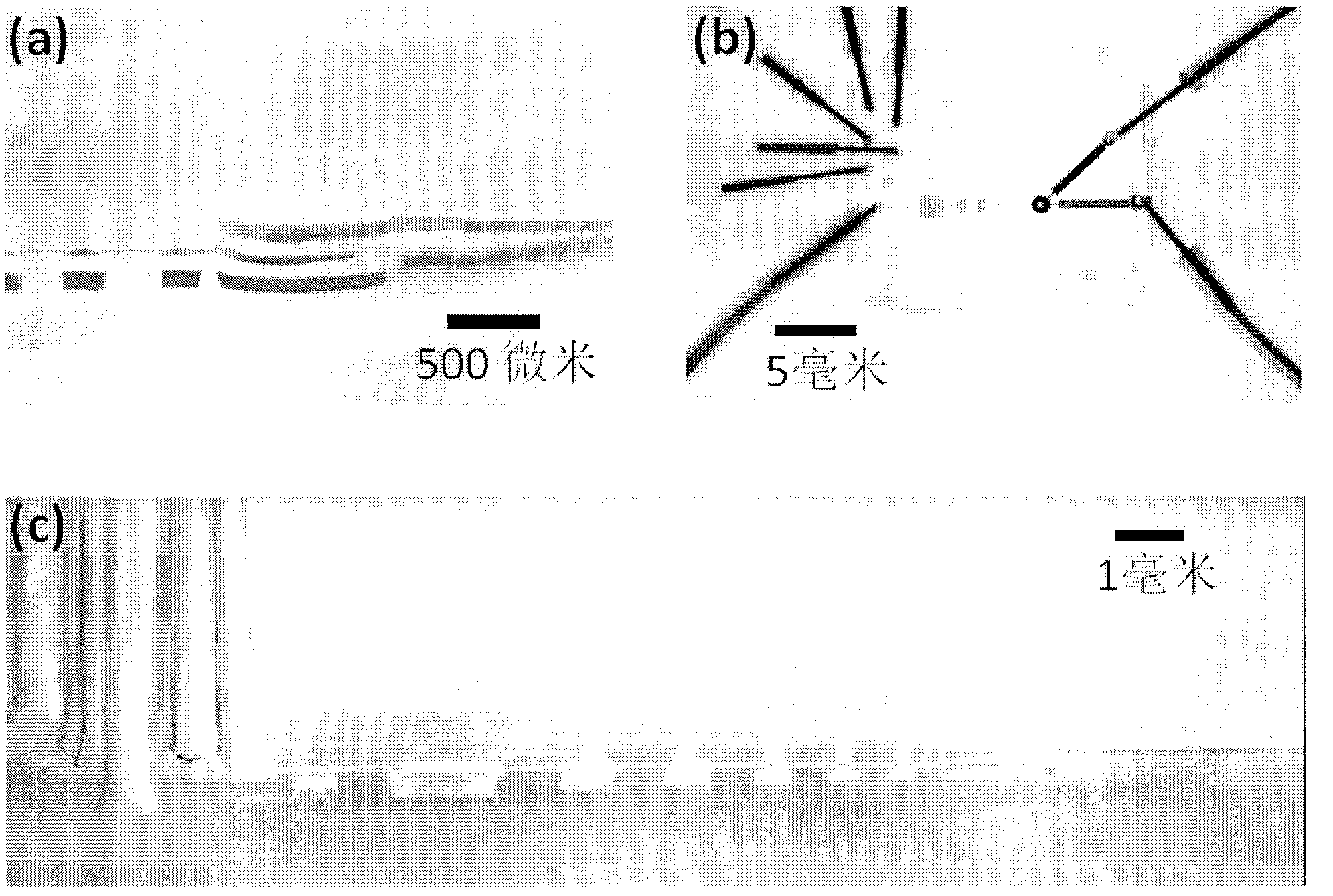

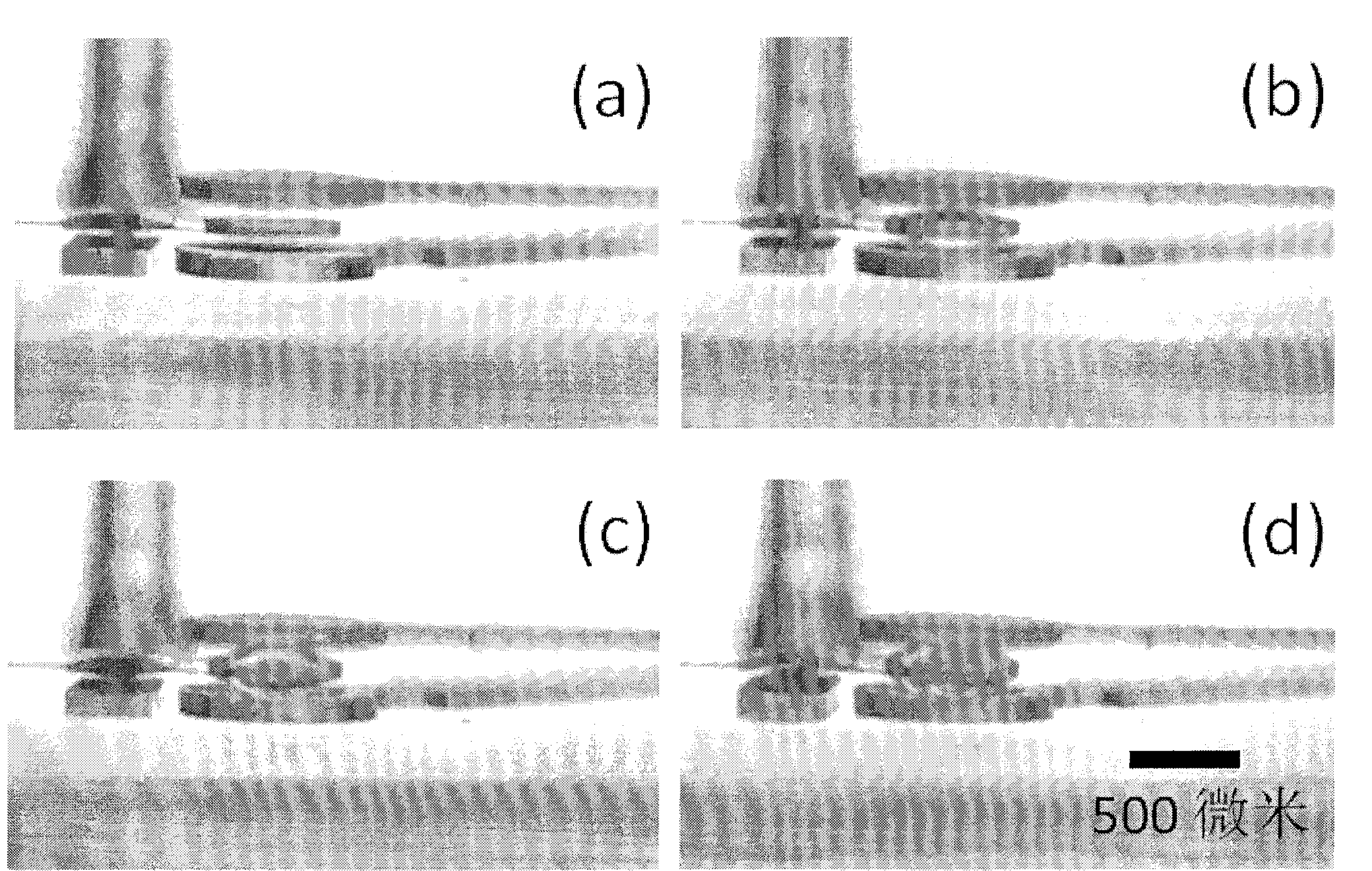

[0025] For the experimental process and results, see Figure 4 and Figure 5 . exist Figure 4 In a, from 0 to 7, we sequentially pressurize and close 7 control valves, the fluid layer liquid is gradually squeezed into the micromirror at the end of the pipeline, and the two layers of PDMS films above and below the micromirror are pressed to deform and expand to both sides accordingly. Extrude the combination of a biconvex mirror with stepwise change of curvature (focal length) plus two single concave mirrors. Figure 4 b clearly shows the process of digital deformation of this compound mirror group. In the experiment, the top and bottom micromirrors are filled with air, which are negative mirrors with large refractive index difference. Therefore, the two negative refractive index single concave mirrors in the compound mirror group become the core components of magnifying (microscopic) imaging. We used AUTOCAD to d...

Embodiment 2

[0027] Micromirror chip zoom performance.

[0028] Compared with the micromirrors developed based on microfluidic technology in the past, the multilayer composite microgroups we prepared have the characteristics of precise and controllable focal length, fast response speed, and various adjustment methods. At the same time, the design of the three-layer structure has a larger numerical aperture than the traditional single-layer micromirror, and the introduction of a new type of large refractive index difference air concave mirror greatly improves the optical magnification ability of the micromirror. We first set the lateral displacement of the central point of the PDMS film with a step size of 5 microns to simulate the various deformation states of the micromirror (states with different curvatures), and then use the optical calculation software Zemax to calculate the mirror group in each state The focal length, and finally get the change curve of the focal length of the lens gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com