Subcritical coordinative control method based on multiple model predictive control

A technology of predictive control and coordinated control, applied in control/regulation systems, adaptive control, general control systems, etc., can solve problems such as unsatisfactory control effect, inability to adapt to large changes in load, load and pressure deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

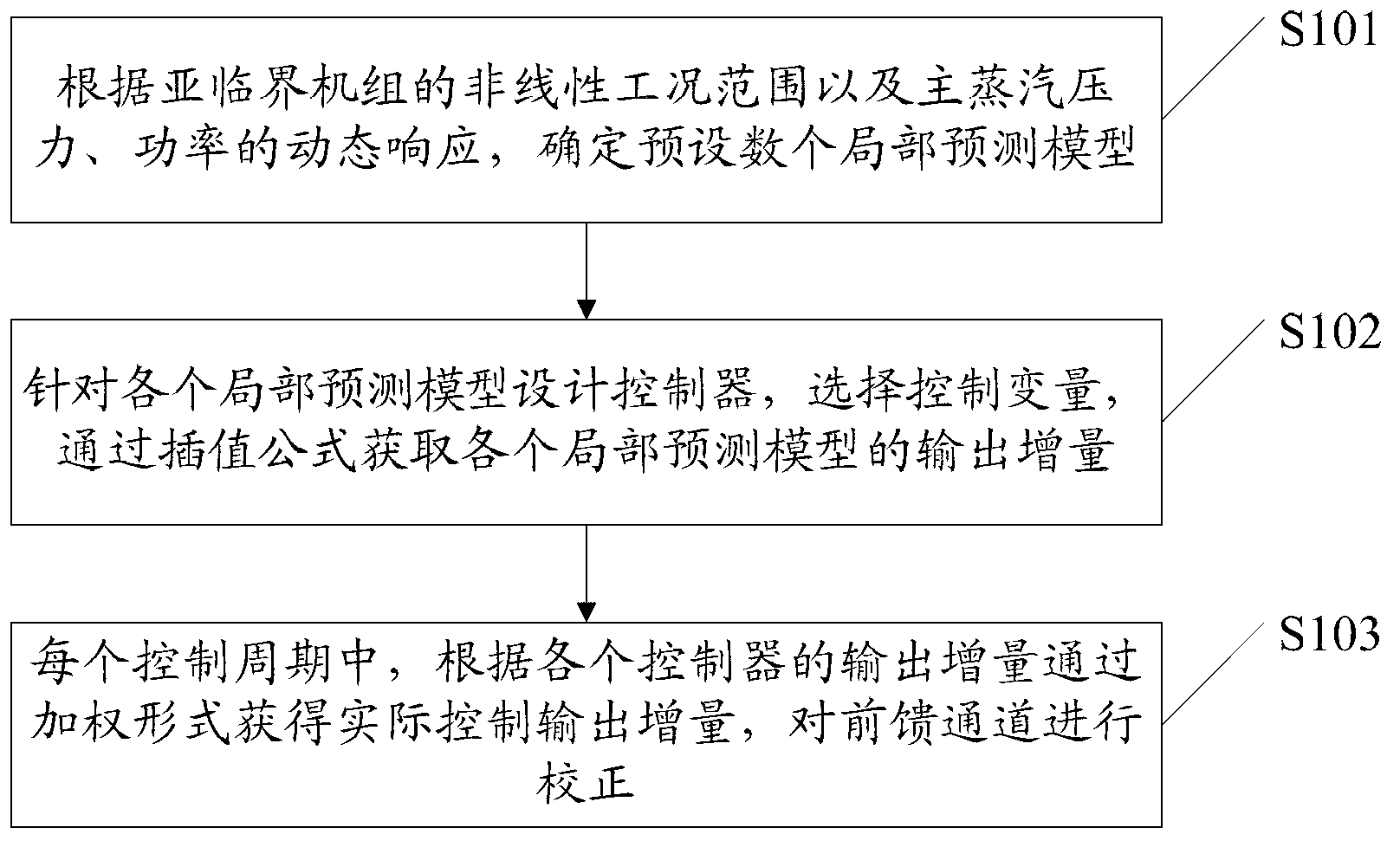

[0016] figure 1 It is a flow chart of the subcritical coordinated control method based on multi-model predictive control in the present invention, including:

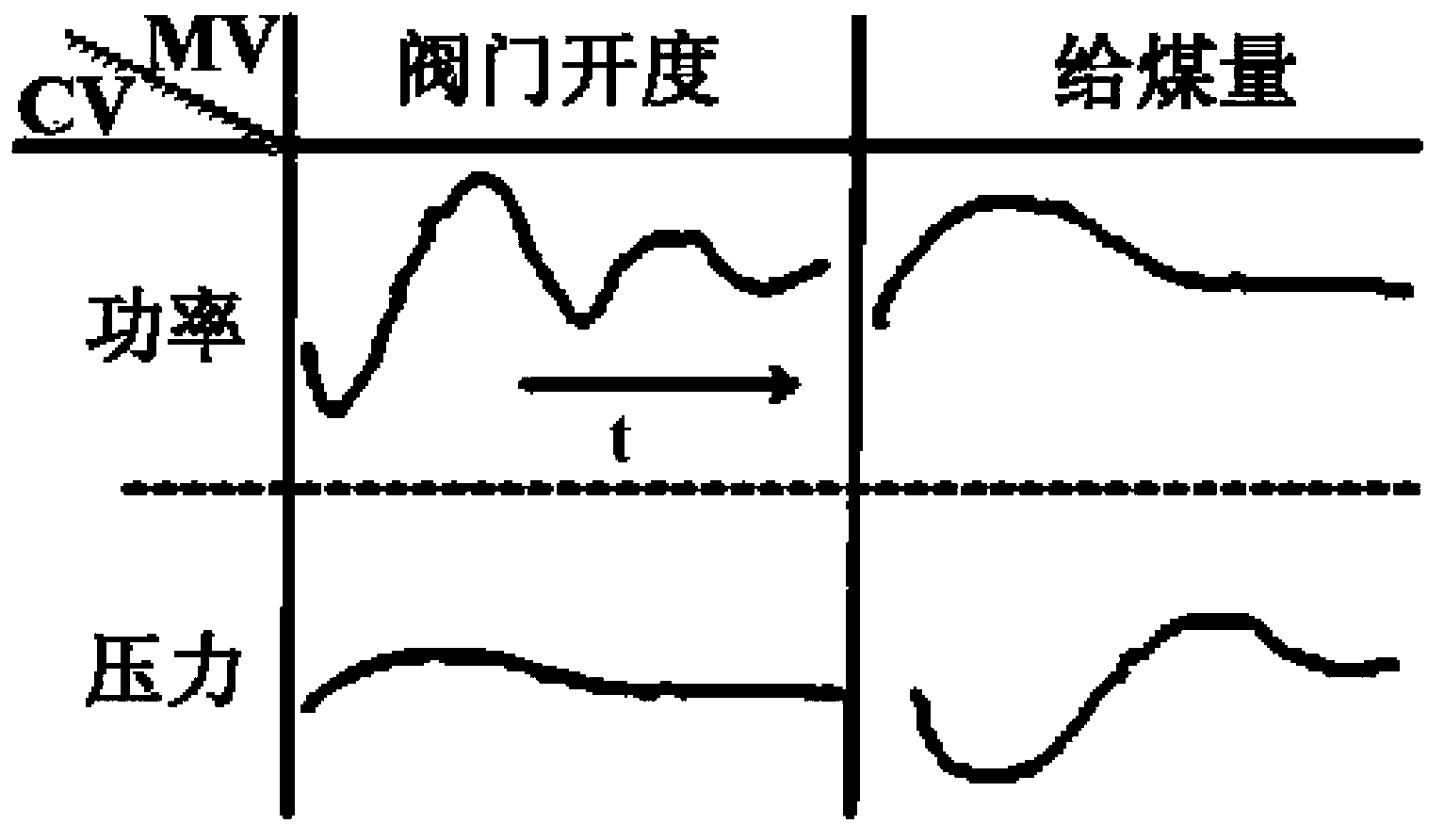

[0017] S101: According to the non-linear operating condition range of the subcritical unit and the dynamic response of the main steam pressure and power, determine several preset local prediction models;

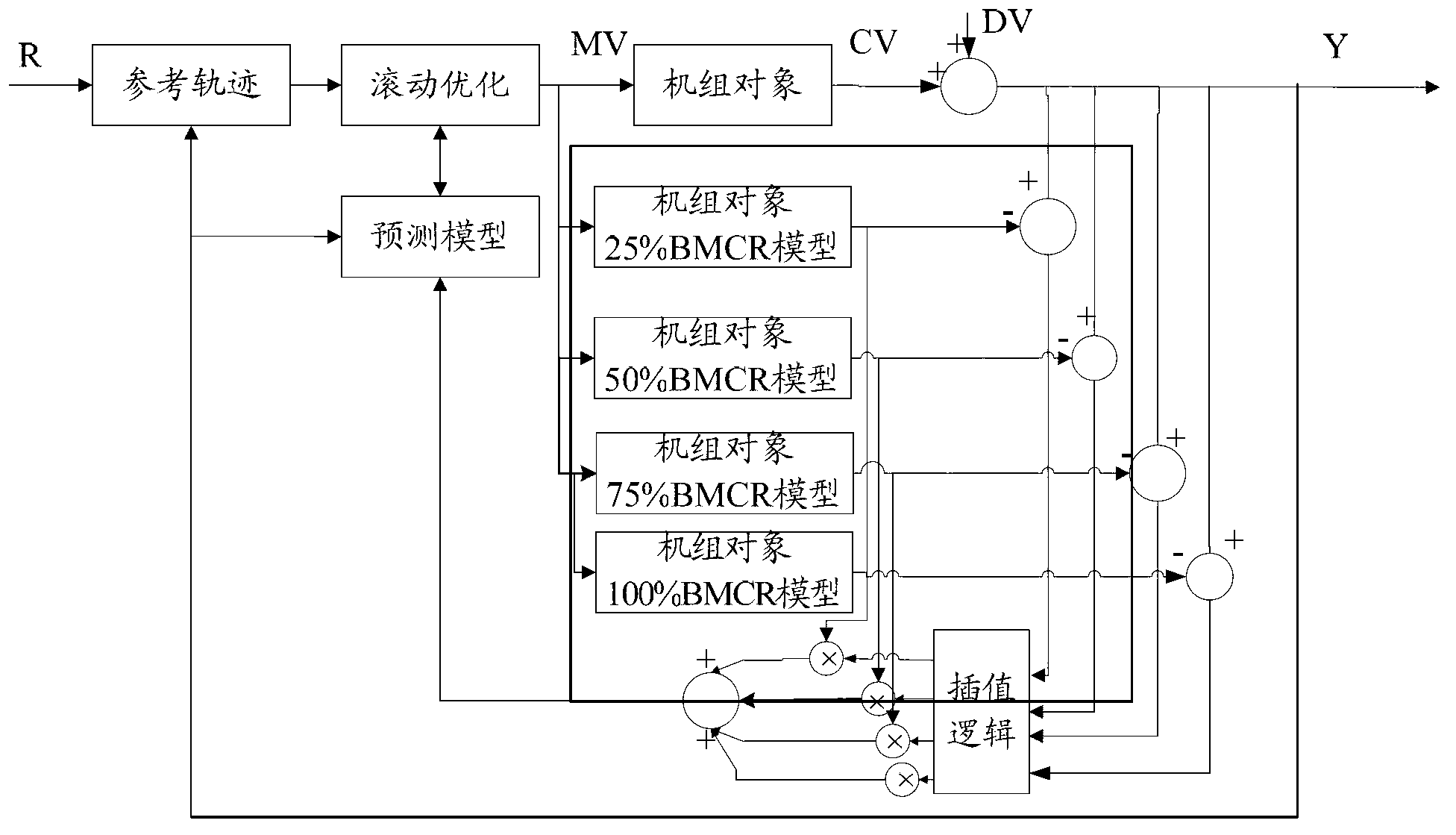

[0018] S102: Design a controller for each local prediction model, select a control variable, and obtain an output increment of each local prediction model through an interpolation formula;

[0019] S103: In each control cycle, the actual control output increment is obtained in a weighted form according to the output increment of each controller, and the feedforward channel is corrected.

[0020] Taking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com