Pile Quality Control Method Based on the Synchronization of Drill Lifting and Piling Speed

A quality control method, the technology of long screw pile machine, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., to achieve the effect of liberating labor force, avoiding necking, and improving pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

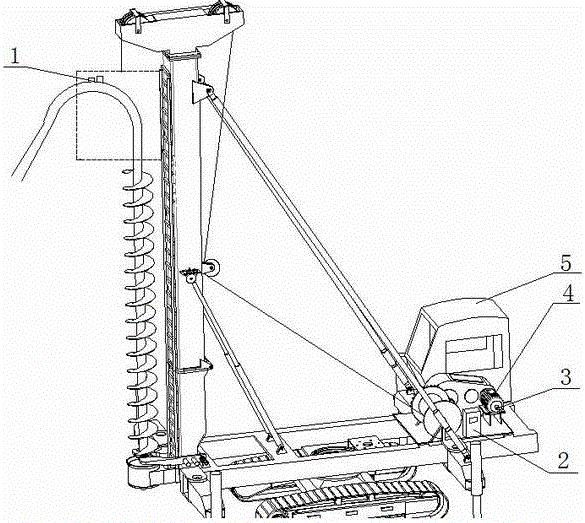

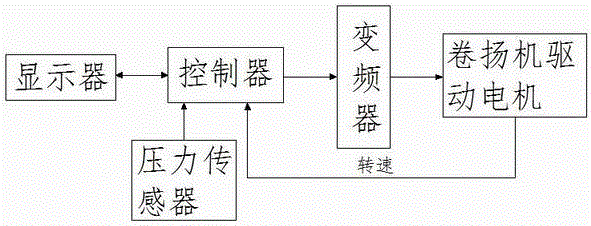

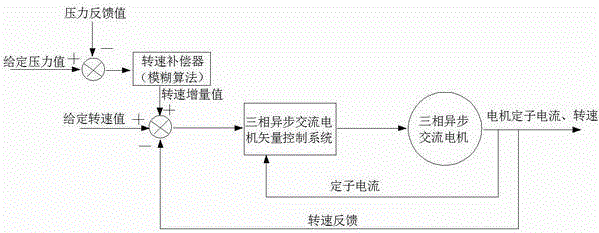

[0023] The present invention solves the problem of mutual coordination and speed matching of drilling, grouting, and pile formation in the drilling process of the long screw pile machine, overcomes the shortcomings of low automation and high labor intensity in the current drilling process, and prevents necking at the same time , broken piles and other quality problems, the present invention proposes a coordinated control scheme based on concrete pressure feedback to synchronize the drilling speed and pile-forming speed, so as to improve the pile-forming quality.

[0024] Since the concrete pressure at the elbow of the power head can reflect whether the concrete in the hollow drill pipe is sufficient, it also indirectly reflects whether the drilling speed is coordinated with the pumping speed of the concrete. Therefore, in this drill lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com