Four-shaft intermediate and low speed full-automatic dispensing robot servo controller

A servo controller and robot technology, applied in the field of automatic beds, can solve the problems of lost pulses, automatic dispensing robot control system occupying a large space, and dispensing motion failure, etc., to improve operation speed and accuracy, and program portability. , the effect of favoring volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

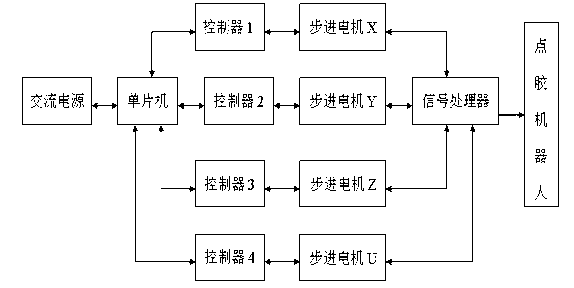

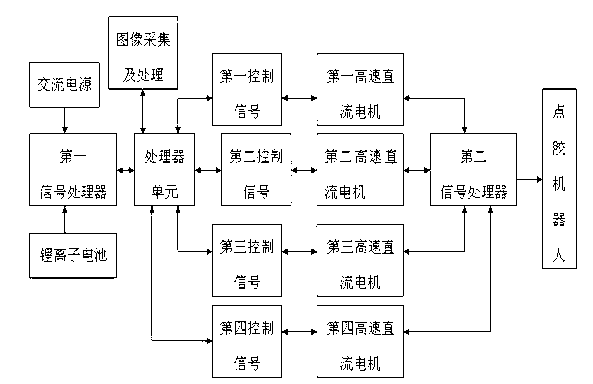

Method used

Image

Examples

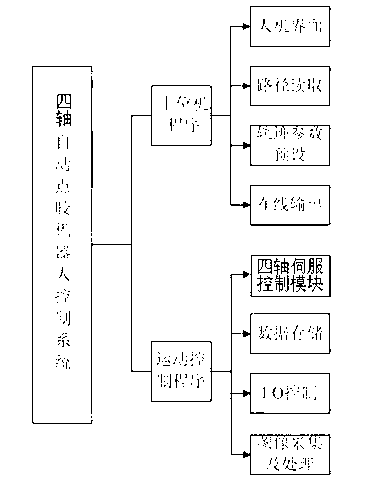

Embodiment Construction

[0040] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0041] Since the birth of single-chip microcomputer in the late 1970s, it has gone through three stages: single-chip microcomputer SCM, microcontroller MCU and system-on-chip SOC. The first two stages are represented by MCS-51 and 80C51 respectively. As the performance and function requirements of single-chip microcomputers in the embedded field are getting higher and higher, the previous single-chip microcomputers cannot meet the new design requirements in terms of operating speed and system integration. At this time, Silicon Labs launched the C8051F series Single-chip microcomputer has become a typical representative of SOC. C8051F has the characteristics of quick start (fully compatible with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com