A preparation method of a chip type ceramic sensitive element and corresponding products thereof

A technology of sensitive components and ceramics, which is applied in the field of sensing and measurement, can solve the problems of silver ion non-ohmic contact, silver-tin solder layer blending, adverse effects on the quality of final products, unfavorable standardized production, etc., to achieve a high degree of automation and eliminate non-ohmic The effect of contact phenomenon and avoiding wire bending or even breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

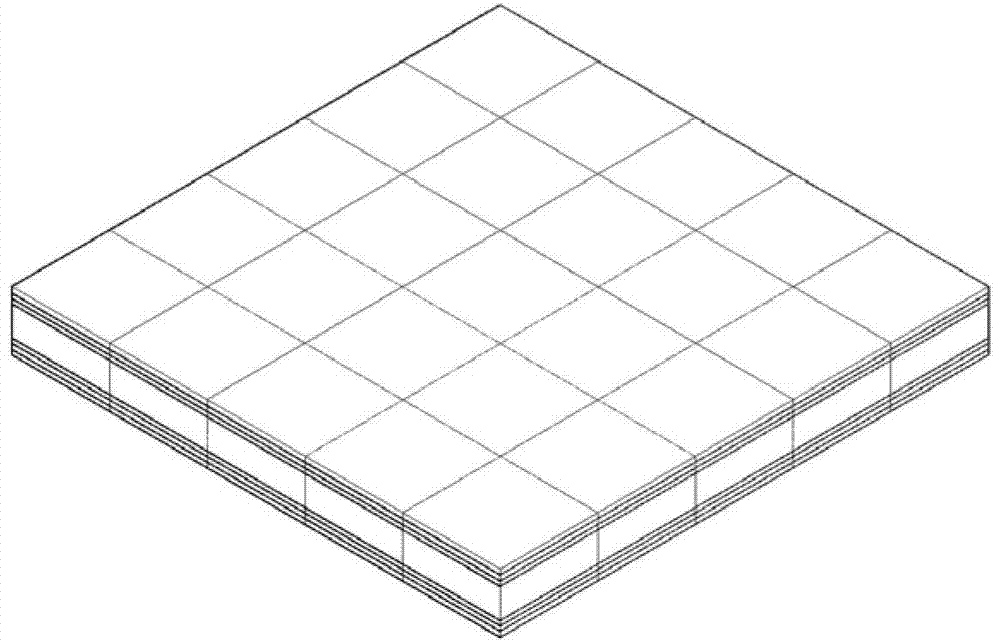

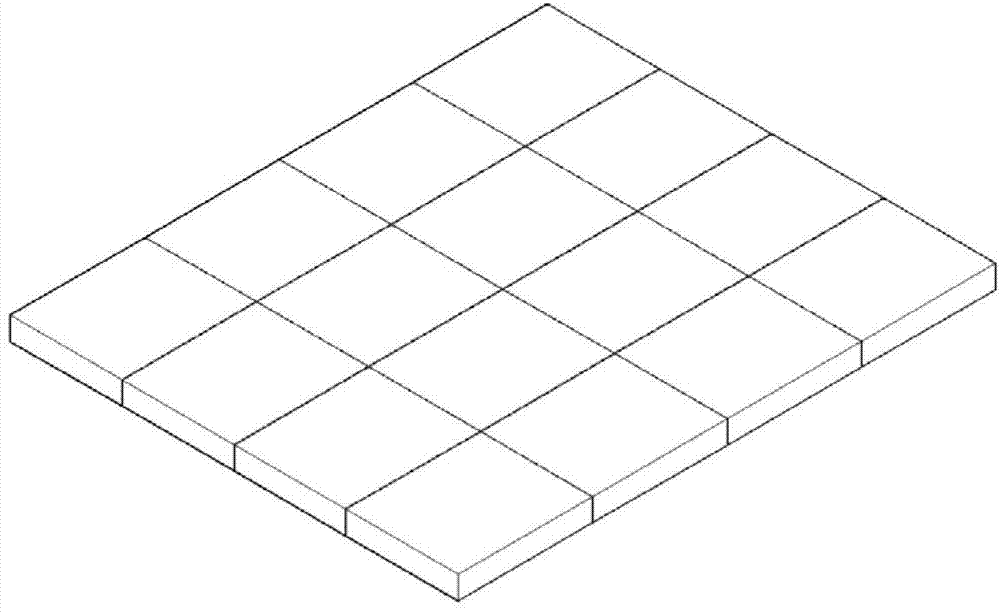

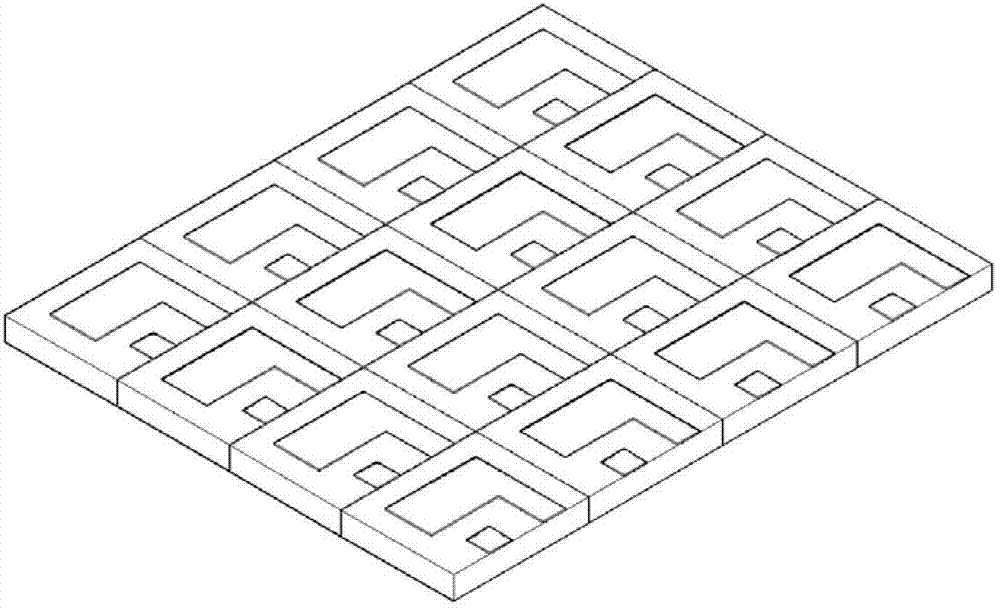

[0040] Figure 1~8 A schematic diagram of the different structures obtained during the preparation method according to the invention is shown. like figure 1 As shown in , first, the preparation steps of the sensitive element body are performed. Taking NTC ceramics as an example, the upper and lower surfaces of NTC ceramics cut into larger pieces (for example, φ50mm disc shape or 50mm×50mm rectangle) can be printed, evaporated, sputtered, etc. respectively. A metal conductive layer is attached to the NTC ceramic sheet. In this embodiment, the metal conductive layer used is a copper layer, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com