Ultrasonic washing device for single crystal silicon wafer

A cleaning device and technology for monocrystalline silicon wafers, which are applied in the field of solar cells, can solve the problems of unclean silicon wafer surface, unclean cleaning in local areas, blocking, etc., and achieve the effects of simple structure, reduced water consumption, and increased cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

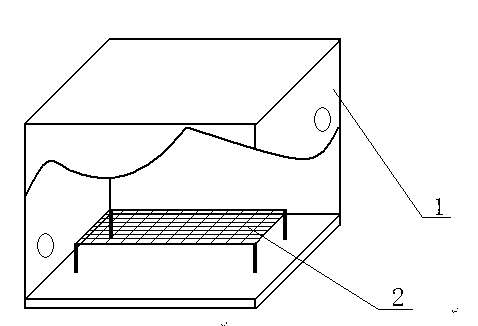

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] as attached figure 1 Shown is an ultrasonic cleaning device for monocrystalline silicon wafers, including a cleaning tank 1 and a frame 2 for placing monocrystalline silicon wafers. The side wall of the cleaning tank 1 is provided with a water inlet and a water outlet for deionized water. The bottom of the tank 1 cavity is provided with an ultrasonic vibrator; the frame 2 includes a quartz grid surface and a support, and the quartz grid surface is placed in the cleaning tank 1 through the support, and the quartz grid surface is lower than the deionized water level and There is a distance from the bottom of the inner cavity of the cleaning tank 1 .

[0012] The above is only a preferred embodiment of the present invention, it should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com