Electronic Control Unit

An electronic control unit and terminal technology, applied in electrical components, circuits, electrical solid devices, etc., can solve the problems of MOSFET or transistor temperature rise, increase in manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

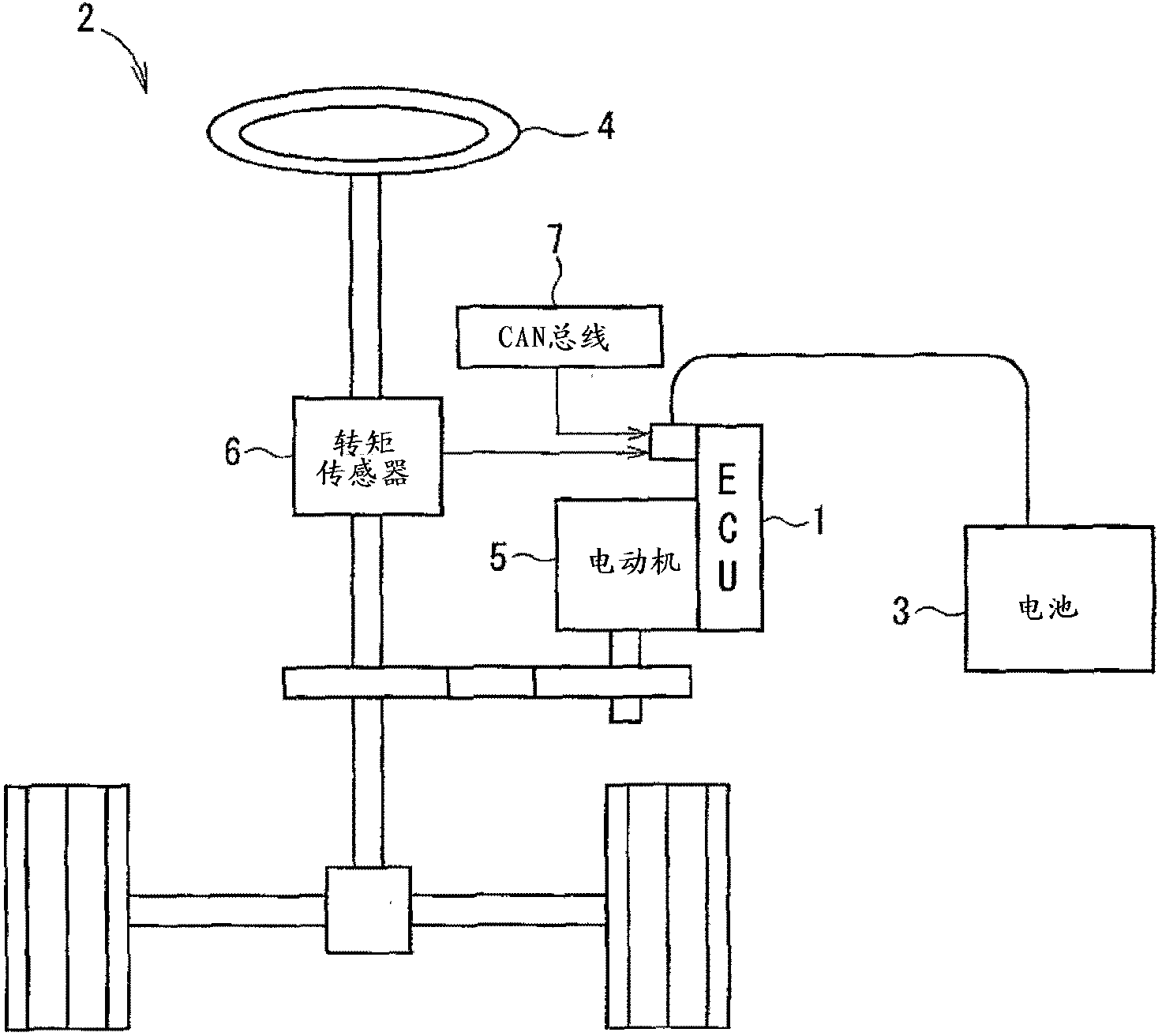

[0036] will refer to Figure 1 to Figure 6 The electronic control unit 1 according to the first embodiment of the present disclosure is described. Such as figure 2 As shown, the electronic control unit 1 can be used in an electric power steering system 2 of a vehicle. The electronic control unit 1 switches the current supplied from the battery 2 to perform drive control of the electric motor 5 for generating an assist force for steering operation to the steering wheel 4 .

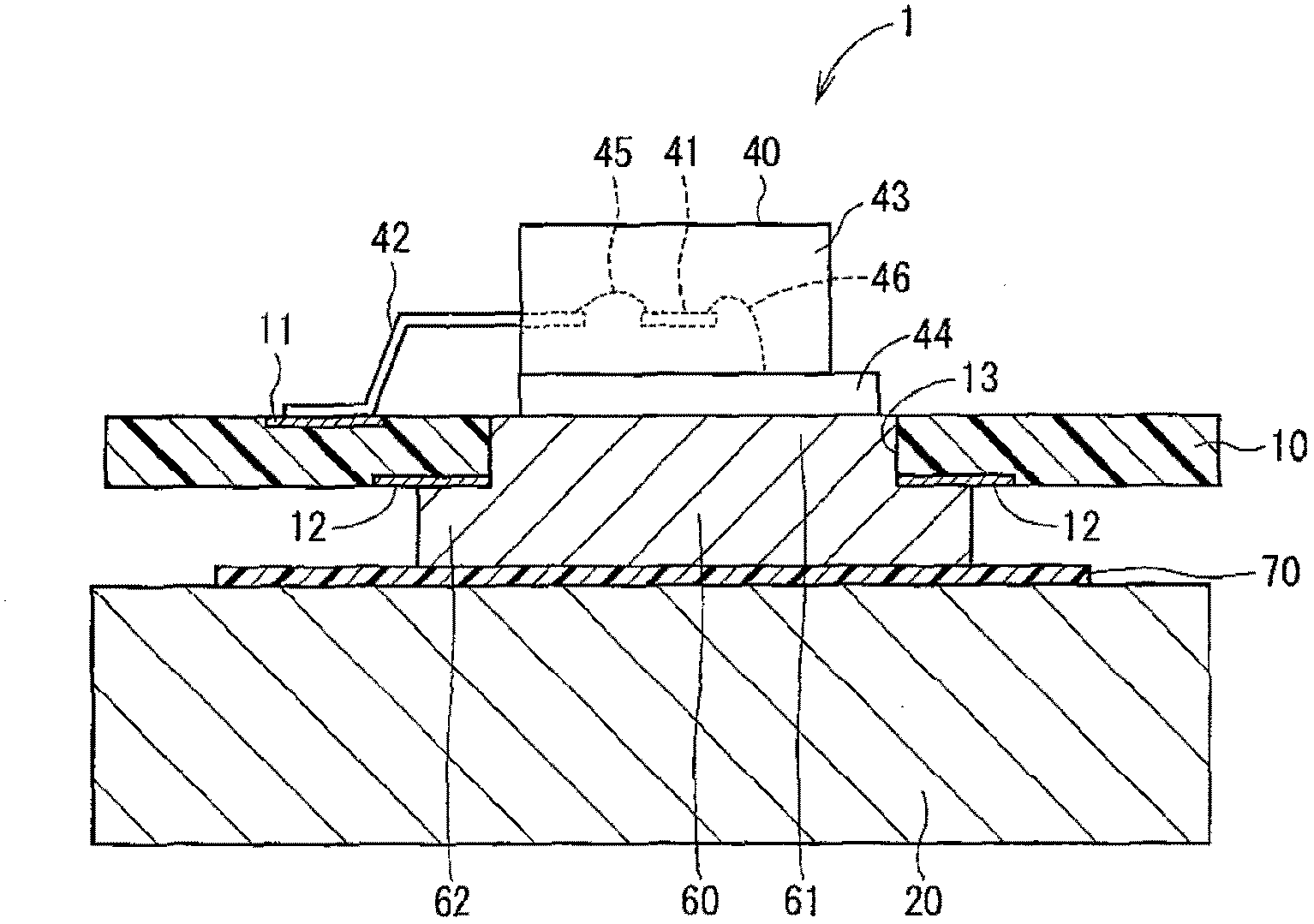

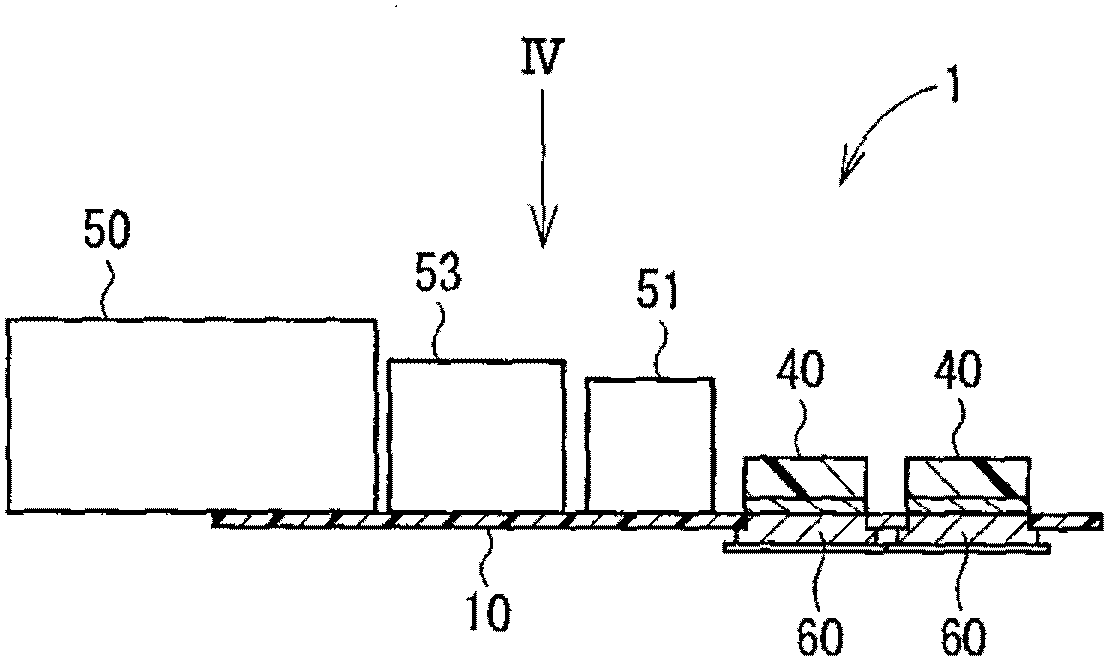

[0037] Such as Figure 3 to Figure 6 As shown, the electronic control unit 1 includes a substrate 10 , a heat sink 20 and a housing 30 . A plurality of electronic components are mounted on the surface of the substrate 10 . The substrate 10 is fixed to a heat sink 20 . The housing 30 is attached to the substrate 10 and the heat sink 20 . The substrate 10 may be a printed wiring board made of FR-4 including glass fiber and epoxy resin. Four MOSFETs 40 are mounted on the surface of the substrate 10 as ...

no. 2 example )

[0051] will refer to Figure 7 to Figure 12 An electronic control unit 1 according to a second embodiment of the present disclosure is described. In this embodiment, components substantially similar to those of the first embodiment described above are denoted by the same reference numerals.

[0052] In this example, if Figure 7 , Figure 8A and Figure 8B As shown, the heat storage body 60 includes a contact portion 63 at each corner of the heat transport portion 62 . The contact portion 63 extends from the heat transport portion 62 toward the substrate 10 . The heat storage body 60 includes an integrated contact part 63 , a heat transfer part 62 and an insertion part 61 . The heat storage body 60 is formed such that the distance H between the end surface of the contact portion 63 facing the substrate 10 and the end surface of the heat transport portion 62 facing the heat sink 20 is precise. In a section parallel to the substrate 10 , the size of the contact portion 63 ...

no. 3 example )

[0056] will refer to Figure 13 An electronic control unit 1 according to a third embodiment of the present disclosure is described. In this embodiment, the area of the surface of the insertion portion 61 facing the heat sink 44 is smaller than the area of the surface of the heat sink 44 facing the insertion portion 61 . The insertion portion 61 and the heat sink 44 are joined to each other by welding. Furthermore, in the present embodiment, when a large current flows into the MOSFET 40 for a short time, the heat sink 44 and the heat storage body 60 store heat, and the temperature rise of the MOSFET 40 can be restricted. When current flows intermittently into the MOSFET 40 for a long time, heat is transferred from the heat storage body 60 to the heat sink 20 via the insulating sheet 70 . Therefore, the temperature rise of MOSFET 40 can be restricted. In the present embodiment, since the area of the surface of the insertion portion 61 facing the heat sink 44 is reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com