Terminal extension structure and manufacturing method thereof

A technology of junction terminal extension and extension area, which is applied to the junction terminal extension structure of high-voltage IGBT and its manufacturing field, can solve the problems affecting the breakdown voltage and reliability of the device, and the influence of the surface electric field, so as to improve the distribution of the surface electric field and reduce the Area, the effect of reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

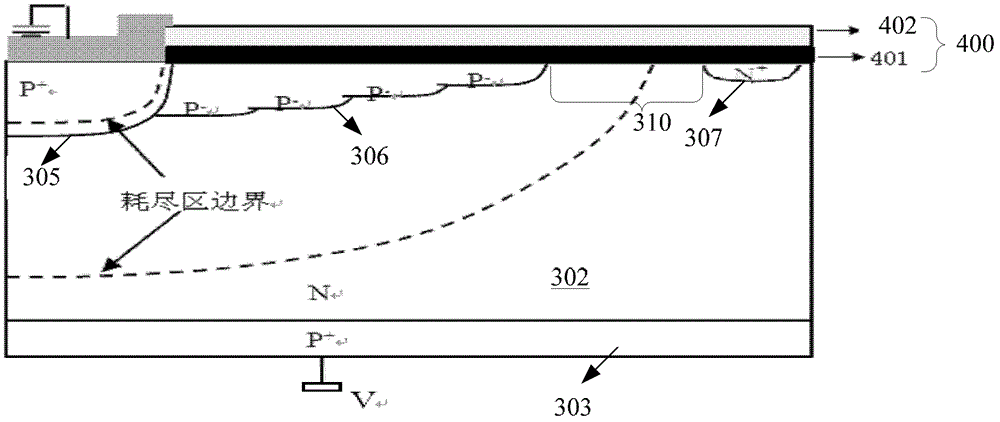

[0047] In this example, refer to image 3 As shown, the junction terminal extension structure includes:

[0048] P + collector area 303;

[0049] P + N on collector region 303 - Drift zone 302;

[0050] N - P on drift zone 302 + The main junction region 305, and the P on the side of the main junction region 305 - Extension 306;

[0051] N outside the extension + cut-off ring 307;

[0052] A stacked structure 400 covering at least the area outside the main junction region 305, the stacked structure 400 includes a semi-insulating polysilicon field plate (SIPOS) 401 and an oxide layer 402, and the oxide layer 402 can be located on the half On the insulating polysilicon field plate 401, there may also be a semi-insulating polysilicon field plate located on the oxide layer, and the semi-insulating polysilicon field plate is located at least part of the extension region 306 and the region between the extension region 306 and the stop ring 307 310 is a continuous structure...

Embodiment 2

[0065] In this example, if Figure 4 As shown, the junction terminal extension structure includes:

[0066] P + collector area 303;

[0067] P + N on collector region 303 - Drift zone 302;

[0068] N - P on drift zone 302 + The main junction region 305, and the P on the side of the main junction region 305 - Extension 306;

[0069] N outside the extension + cut-off ring 307;

[0070] Covering at least the stacked structure 400 outside the main junction region, the field plate is a metal field plate, the stacked structure 400 includes an oxide layer 501 and a metal field plate 502 on the oxide layer 501, the metal The field plate 502 is located on the oxide layer 501 and is a continuous structure located on at least part of the extension region 306 and at least a part of the region between the extension region 306 and the stop ring 307 .

[0071] In this embodiment, the metal field plate can completely cover the extension region and the area between the extension reg...

Embodiment 3

[0081] In this embodiment, by forming a multilevel field plate combined with a polysilicon (POLY) field plate and a metal field plate, the polysilicon (POLY) field plate and the metal field plate are separated by an oxide, while shielding the interface charges, by Optimize the influence of the thickness of the oxide layer on breakdown, improve the phenomenon of surface electric field concentration, suppress premature breakdown, better stabilize the breakdown voltage of the device and improve the reliability of the device.

[0082] refer to Figure 5 As shown, the junction terminal extension structure includes:

[0083] P + collector area 303;

[0084] P + N drift region 302 on collector region 303;

[0085] P on N drift region 302 + The main junction region 305, and the P on the side of the main junction region 305 - Extension 306;

[0086] N outside the extension + cut-off ring 307;

[0087] The stacked structure 400 at least partially covering the area outside the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com