Electrical heater and fabricating method thereof, and vehicle

An electric heater and the technology of the manufacturing method are applied in the direction of ohmic resistance heating parts, heating elements, heating/cooling equipment, etc., which can solve the problem of poor heat conduction and heat dissipation, and the heating system is not suitable for defrosting, defogging and heating, and cannot Adapt to problems such as long-term use of automobiles, achieve high heating efficiency, good heat dissipation effect, and good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

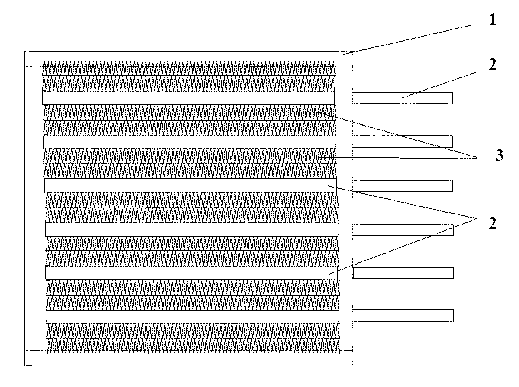

[0038] This embodiment combines figure 1 For illustrating the making of electric heater of the present invention:

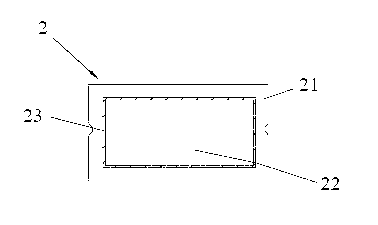

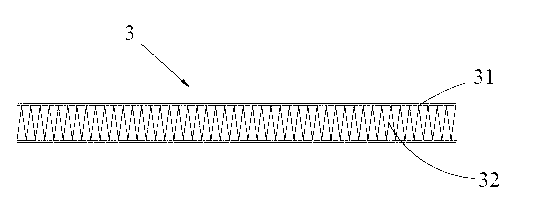

[0039] Step 1. Provide a square frame, 7 corrugated aluminum cooling strips, and provide 6 aluminum square tubes and multiple PTC thermistors, and install the multiple PTC thermistors on the six Six heating elements are formed in the aluminum square tube;

[0040] Step 2. Use the sandblasting process to perform sandblasting treatment on the surface of the aluminum square that is connected to the heat dissipation strip to form the first sandblasting surface; the sandblasting process uses compressed air as the power to spray the spray material to the surface to be treated at high speed , the pressure of the compressed air is 4Kg / m 2 , the spray material uses quartz sand, the particle size of the quartz sand is 40 microns, the purity is higher than 99.5%, and the flow rate of the quartz sand is 1.0m 3 / min;

[0041] Step 3. The 6 heating elements and the 14 heat...

Embodiment 2

[0043] The manufacturing method of the electric heater in embodiment 2 is basically the same as that in embodiment 1, the difference is that step 2 also includes sandblasting the surface of the heat dissipation strip used to connect with the aluminum square to form a second sandblasting process by using a sandblasting process. surface; step 3, heat-conducting silica gel is arranged between the first sandblasting surface of the aluminum square tube and the second sandblasting surface of the adjacent heat dissipation strip, and the electric heater A2 is obtained by the manufacturing method of Example 2.

Embodiment 3

[0045] The manufacturing method of the electric heater of embodiment 3 is basically the same as that of embodiment 1, the difference is that the number of corrugated aluminum heat dissipation strips provided in step 1 is 7, and the number of adjacent two heating elements in step 3 is One heat dissipation strip is provided, and one heat dissipation strip is provided between the outermost heating element and the frame, and the electric heater A3 is manufactured by the manufacturing method of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com