Resistance welding method suitable for multi-point circumferentially-arranged sheets

A circular arrangement and resistance welding technology, which is applied in the field of mechanical equipment and welding, can solve the problems of increased residual stress and welding deformation of workpieces, inability to realize workpiece welding, and high labor intensity of workers, so as to improve welding efficiency, improve welding quality and Welding efficiency and the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

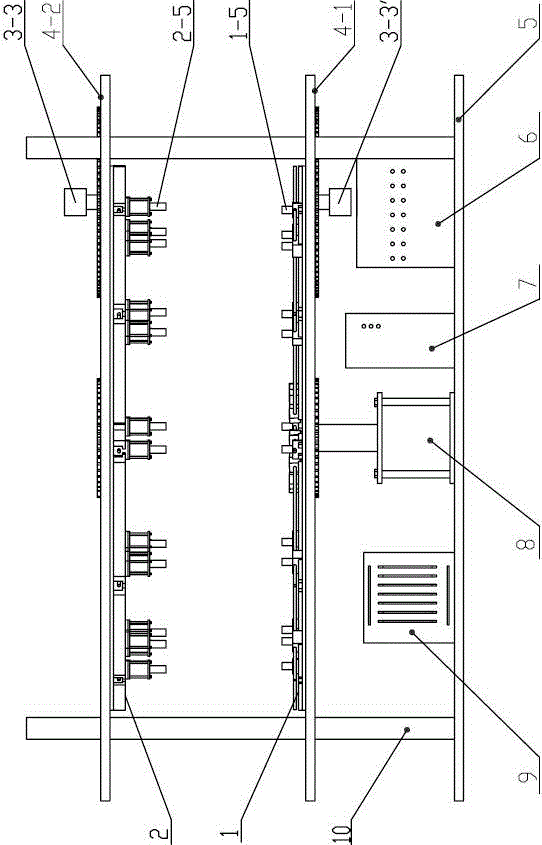

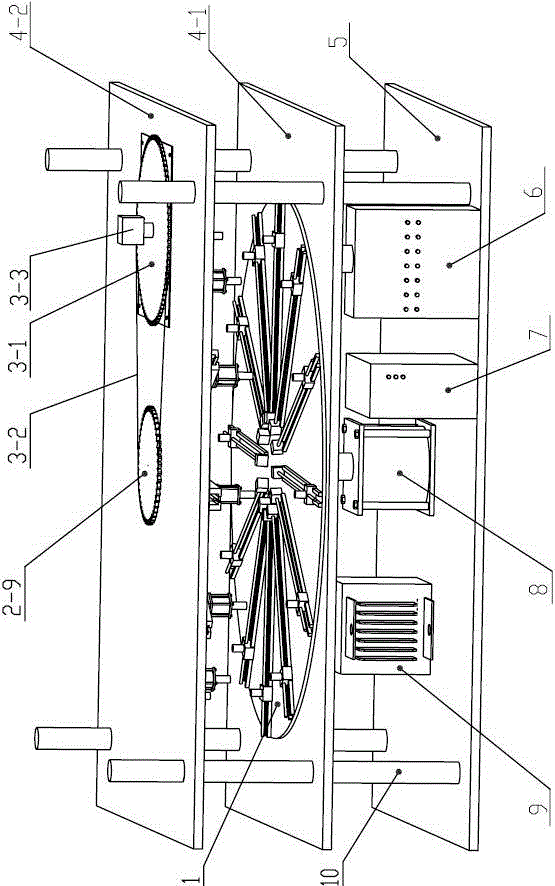

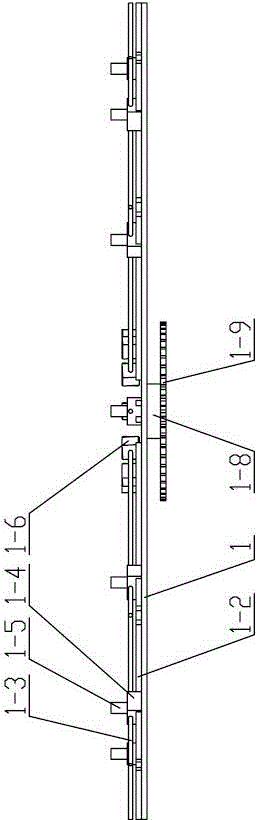

[0029] Such as figure 1 Shown is the structural representation of equipment of the present invention, figure 2 Shown is figure 1 A schematic diagram of the three-dimensional structure. The resistance welding equipment of the present invention includes a base 5 on which a PLC cylinder control cabinet 6, a stepping motor control cabinet 7, a lifting cylinder 8 and a transformer 9 are installed; the base 5 is arranged horizontally and fixed on the ground by bolts arranged at its four corners On, frame 10 is fixed on the base 5. The top of frame 10 is fixed with upper workbench 4-2, and last rotary tray 2 is installed on the bottom of upper workbench 4-2, and lower workbench 4-1 is installed between upper workbench 4-2 and base 5, and lower The rotating tray 1 is installed on the lower workbench 4-1, a pair of rotating trays 2 and 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com