Borate lanthanide optical glass

An optical glass and borate technology, applied in the field of borate lanthanide optical glass, can solve problems such as the deterioration of glass crystallization performance, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

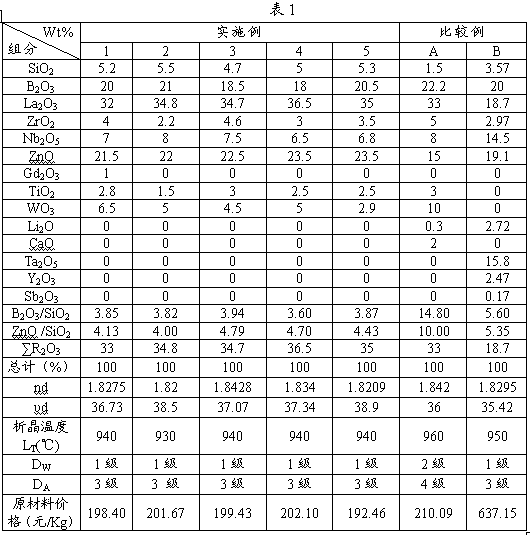

[0036] Examples 1 to 5 listed in the following table 1 are used to illustrate the borate lanthanide optics obtained with a refractive index (nd) between 1.82 and 1.84 and an Abbe number (υd) between 35 and 39 according to the present invention. Specific embodiments of glass. Comparative Examples A and B are comparative embodiments with a refractive index between 1.82-1.84 and an Abbe number between 35-39.

[0037] Calculate, weigh, and mix these raw materials according to the ratio provided in Table 1, and put the prepared batch into the smelting device (in view of the application requirements of the present invention, the smelting device needs to use a platinum crucible), and then take After smelting with proper mixing, clarification and cooling process, it is poured or leaked into the forming mold. Finally, after post-processing such as annealing and processing, or directly pressing and forming through precision pressing technology, the borate lanthanide optical glass or op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com