Fixed aerobic composting reactor

An aerobic composting and reactor technology, applied in application, organic fertilizer, fertilization device, etc., can solve the problems of energy consumption, fertilizer agglomeration, low oxygen supply efficiency, etc., and achieve the goal of reducing heat loss, strengthening effect, and high-efficiency fermentation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

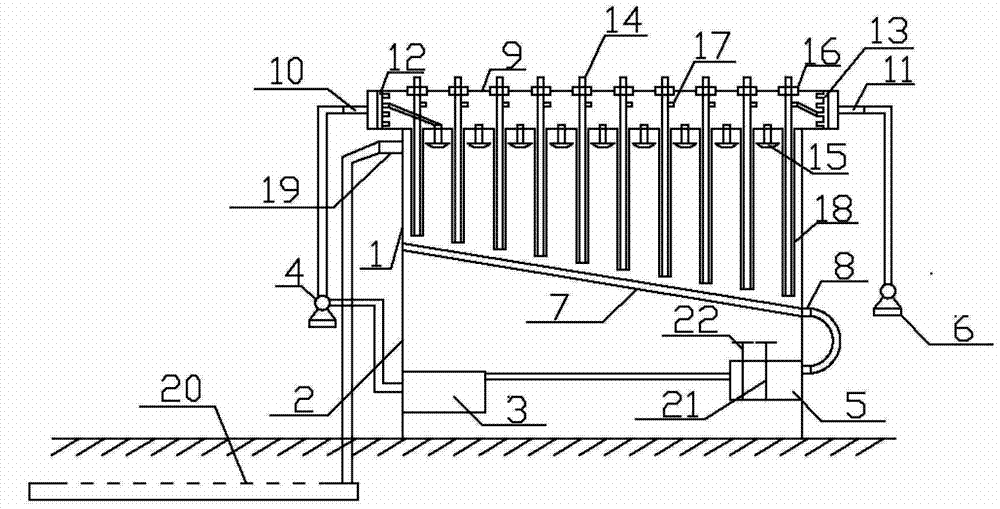

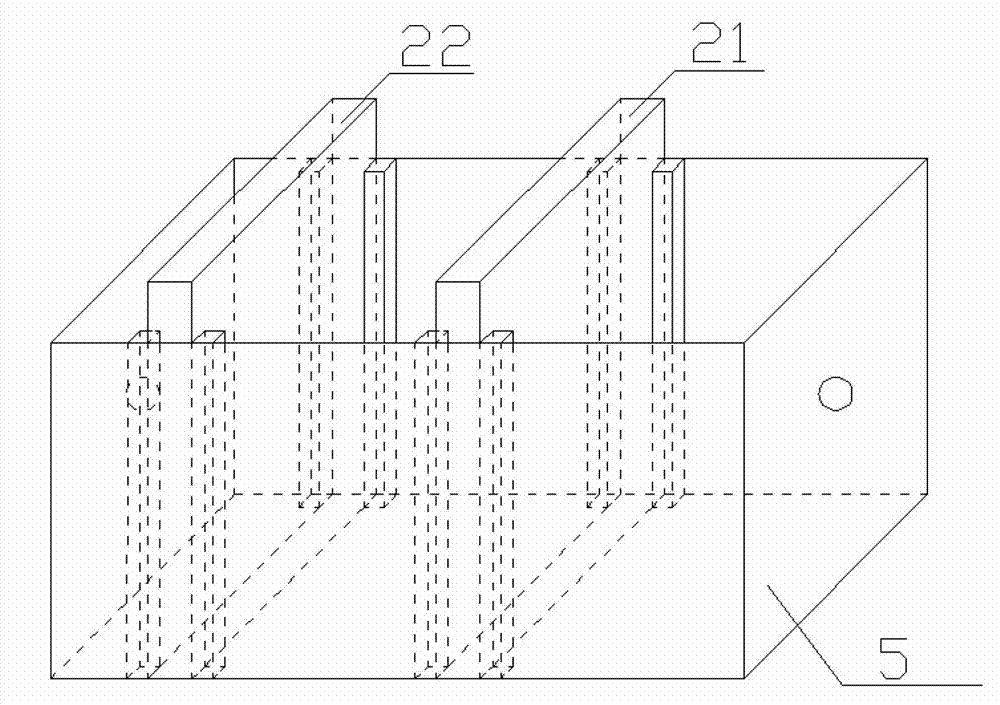

[0015] A stationary aerobic composting reactor such as figure 1 As shown, it includes reaction chamber 1, support 2, water tank 3, water pump 4, filter tank 5 and fan 6, reaction chamber 1 is a rectangular airtight box, the bottom plate of the box is a slanted plate with a slope of 45°, and the middle of the slanted plate is set There is a rectangular groove 7, the bottom of the groove is provided with a reaction chamber liquid outlet 8, the top of the box is provided with a detachable top cover 9, the top cover 9 is a closed sandwich structure, and the upper and lower plates of the top cover are respectively evenly distributed with The two sides of the top cover 9 are provided with a water inlet 10 and an air inlet 11 respectively, and a water distribution plate 12 and an air distribution plate 13 are respectively provided in the inlet. The water distribution plate 12 and the air distribution plate 13 are both airtight interlayer structures. The inner plates of the interlayer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com