Pavement structure based on water sand backfilling technology and construction method thereof

A technology of pavement structure and construction method, which is applied to roads, roads, buildings, etc., can solve problems such as pipeline damage, complicated construction procedures, and insufficient bearing capacity, and achieve the goals of enhancing foundation bearing capacity, preventing uneven settlement, and shortening the construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

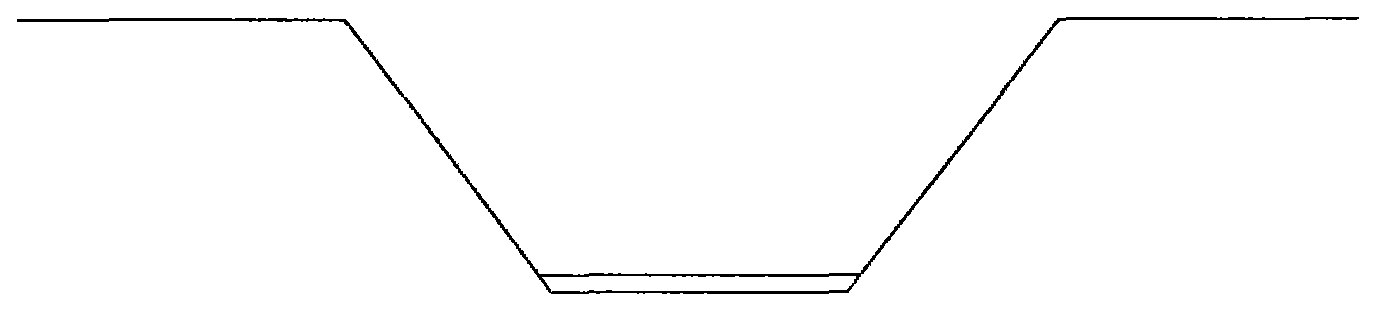

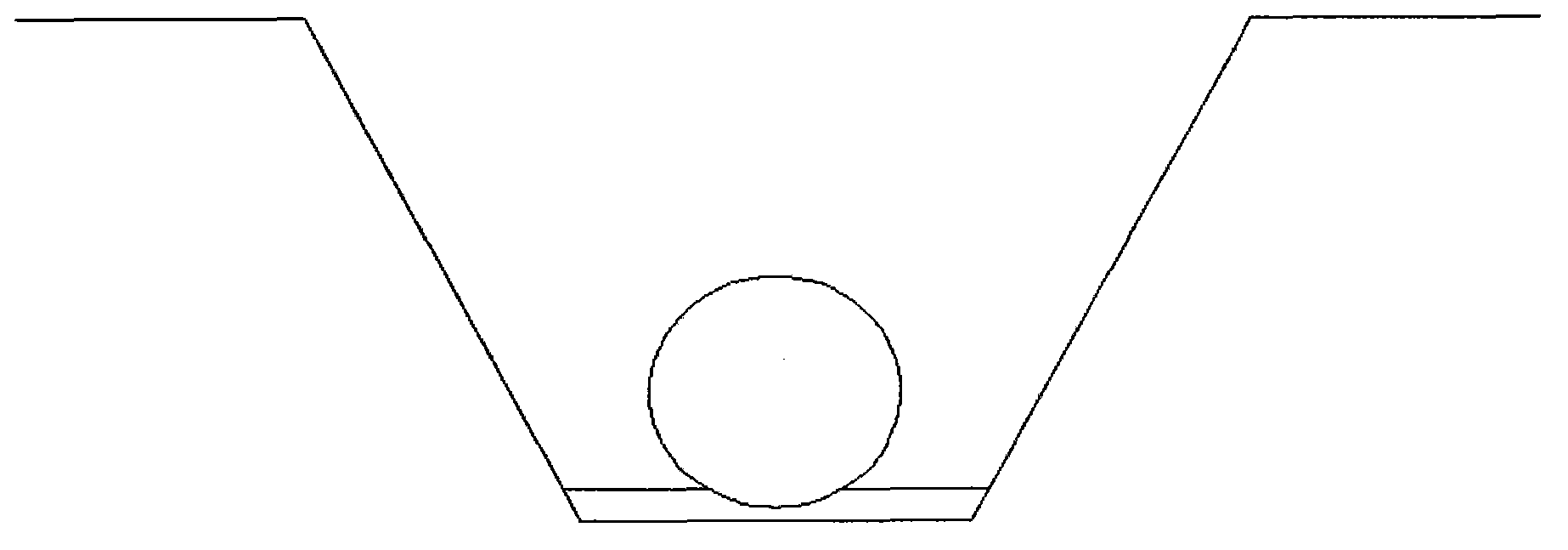

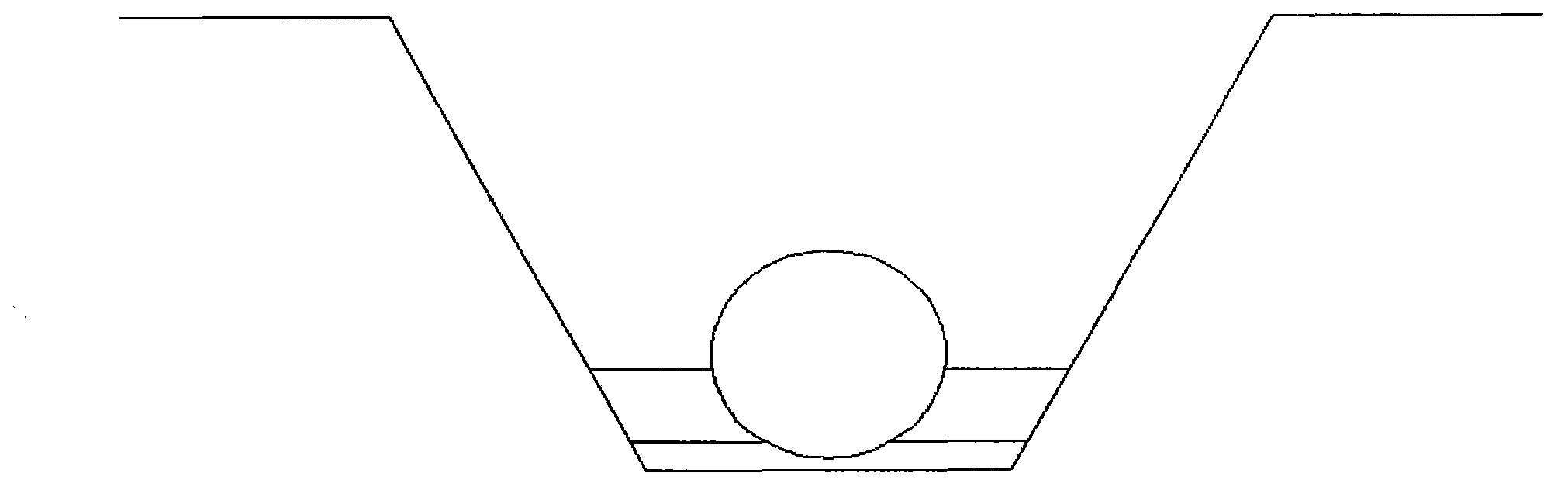

[0034] The technical solutions and specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0035] A construction method of pavement structure based on water shaking sand backfilling technology, comprising the following steps:

[0036] 1) According to the situation of the project site, after grooving, select the appropriate spacing for use in sections, the spacing is generally about 50m, mainly considering the on-site traffic, construction period, and the utilization of circulating water in the water-shaking process, and make appropriate adjustments according to the site;

[0037] 2) After the groove reaches the design depth, first check whether the bearing capacity of the bottom of the groove meets the requirements, generally reaching 100KP. If it does not meet the requirements, it is necessary to replace the pipe foundation to ensure the bearing capacity of the pipe foundation.

[0038] 3) Check whether the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com